The Challenge

Building Pallets of Mixed Carton Formats at High Throughput

Manual pallet stacking and case handling was inefficient, inconsistent, and ergonomically challenging. The customer needed a solution to:

- Automatically pick and layer cases of various sizes and patterns

- Insert slip-sheets and wrap pallets without manual labor

- Achieve stack integrity suitable for transportation and storage

- Scale throughput while reducing labor reliance

MWES was chosen for their expertise in robotics-based palletization systems capable of handling variable carton sizes and complex pallet stacking logic.

The Solution

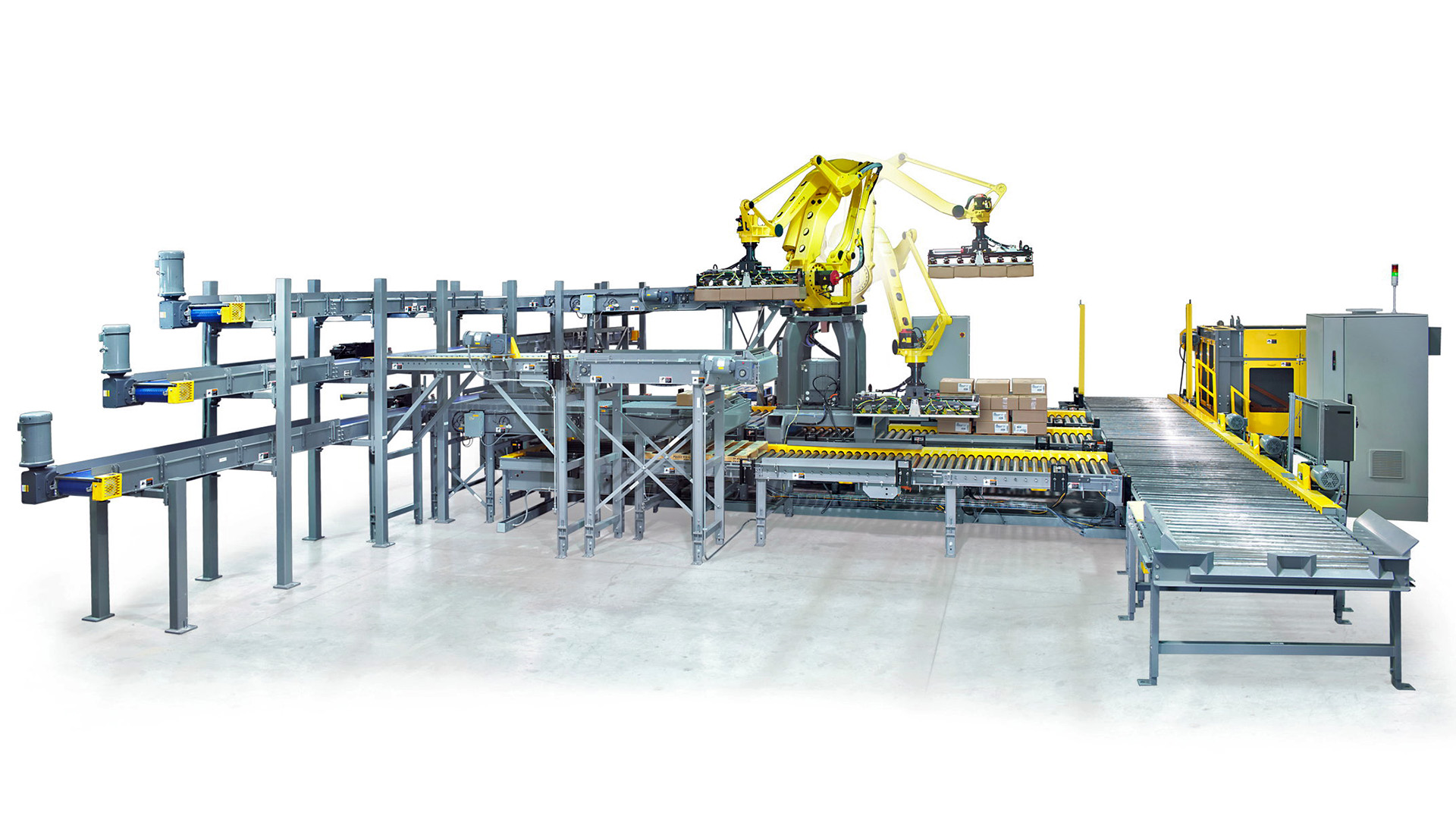

Custom Robot Cell Integrating Layer Patterning, Slip Sheets & Wrapping

MWES engineered a full robotic palletizing solution featuring:

- A high-payload floor-mounted robot capable of row and layer picking

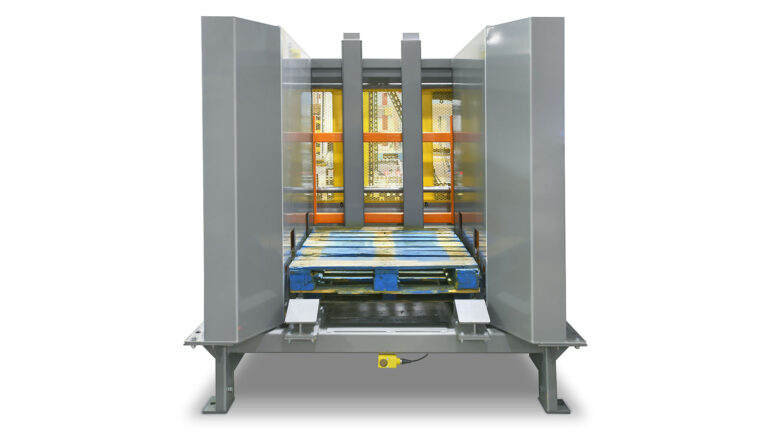

- Automated slip-sheet insertion between layers to support heavy loads

- Recipe-driven pattern logic allowing mixed-case stacking and pallet height adjustments

- Integrated stretch wrapping station after pallet build-out

- Compact safety fencing, pallet dispenser, and HMI interface for operators

This turnkey system delivers fully automated pallet builds—from loading cases to wrapped, finished pallets—without manual stacking or rehandling.

The Results

Faster Pallet Builds, Labor Reduction & Improved Load Quality

The automation delivered measurable operational benefits:

- Increased stacking rate to more than 4 layers per minute

- Eliminated repetitive manual pallet stacking and reduced ergonomic risk

- Maintained stable pallet integrity with slip-sheet reinforcement

- Supported multi-SKU pallets with recipe changeover and minimal operator input

By automating full-pallet assembly, MWES helped the customer boost productivity, improve load quality, and reduce labor dependency—all within a modular, scalable palletizing module.