The Challenge

Robotic Assembly Required to Mitigate Labor Shortages & Improve Quality

Relying on manual assembly posed risks due to workforce variability, increasing defect rates and inconsistent output. The customer needed automation to:

- Assemble a range of hair trimmer models reliably and efficiently

- Maintain high build quality and minimize human error

- Integrate laser marking and packing inline

- Handle reject logic and part tracking automatically

MWES was selected for their track record in flexible robotic assembly systems for consumer electronics production.

The Solution

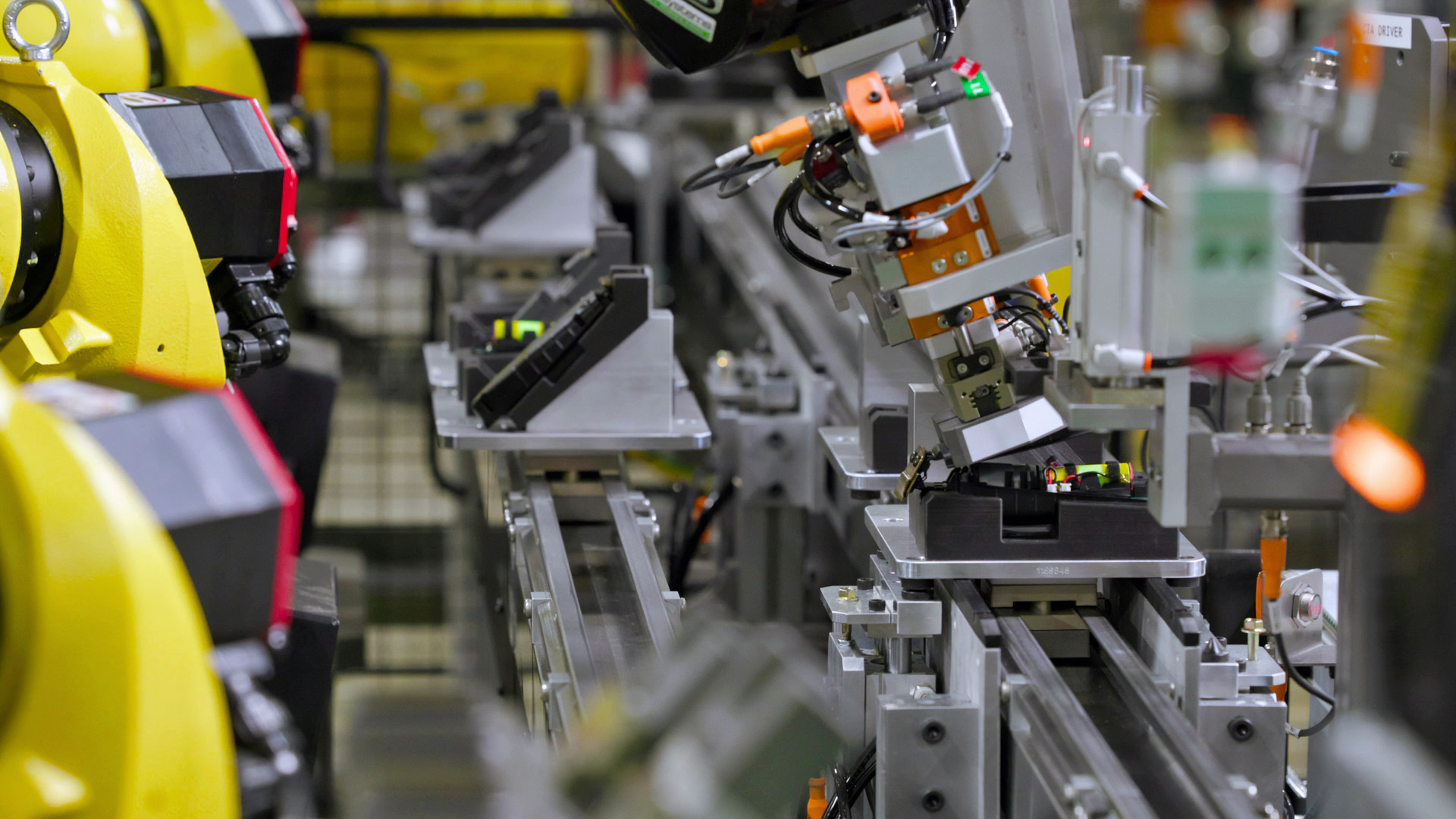

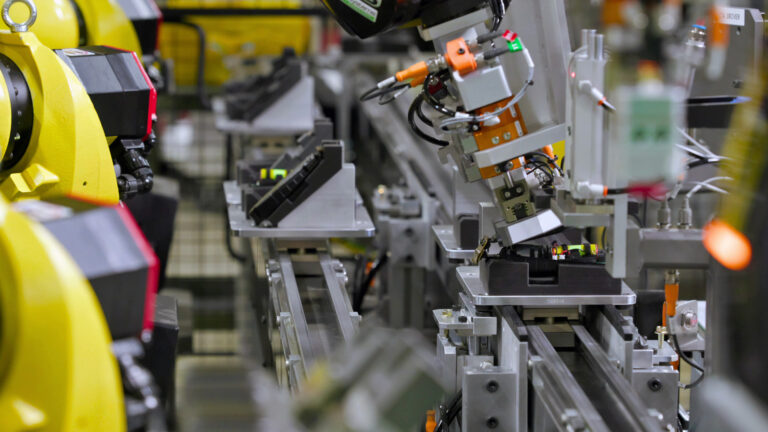

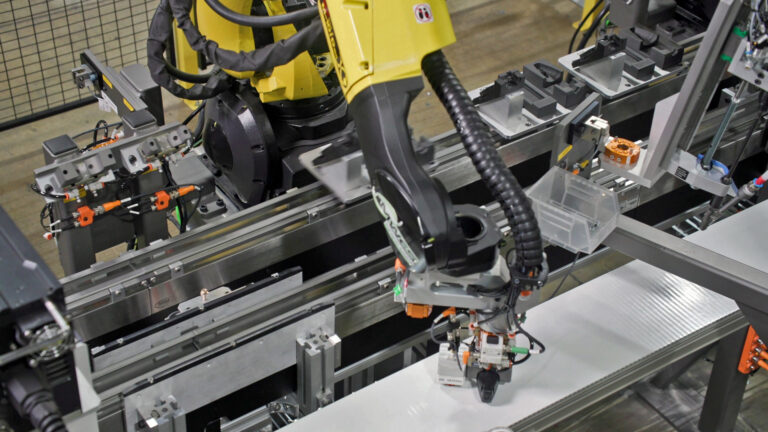

Three-Station Robotic Assembly Line with Integrated Vision and Laser Marking

MWES delivered a compact, turnkey assembly line including:

- Three robot stations handling fastening, housing placement, and part insertion

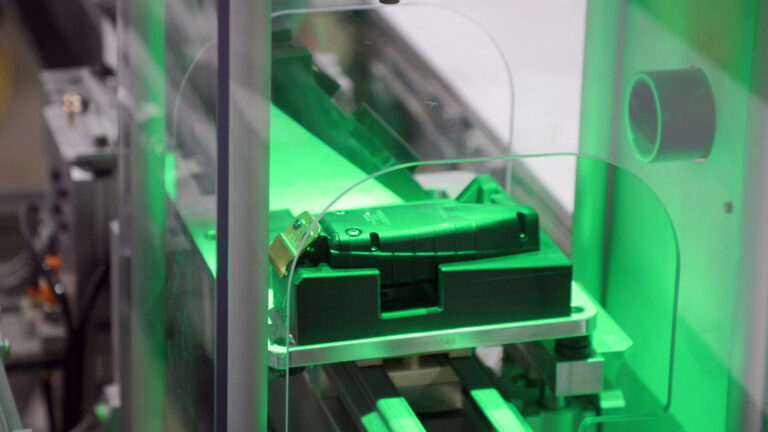

- Conveyor-fed part fixtures with vision-based part verification at each handoff

- Barcode scanning and laser marking station for serialized traceability

- Operator load station and downstream test-and-pack area staffed by two people

This system unifies assembly, vision inspection, marking, and packing into an efficient production flow. The result delivers high consistency with minimal labor dependency.

The Results

Scalable Production with Improved Quality & Reduced Labor Needs

Implementation of the line produced measurable benefits:

- High-rate assembly of multiple trimmer models per shift

- Nearly 100% part traceability via barcode and laser marking

- Elimination of assembly errors and improved consistency

- Only three operators needed (one at load, two at pack/test)

By automating core assembly, quality verification, and marking, MWES helped the customer reliably scale trimmer production with better quality control and lower labor overhead.