The Challenge

Eliminating Variability in Connecting Rod Assembly via Automation

Achieving consistent assembly quality across high-volume engine connecting rods was a major challenge. Manual bolt installation had led to inconsistent torque, alignment issues, and rework. The main objectives were:

- Automate the installation and exact torque of four cap bolts per rod

- Maintain assembly precision across variable rod geometries

- Reduce errors and eliminate manual handling risks

- Deliver consistent throughput in a lights‑out assembly environment

MWES was selected for its experience integrating robotic high-torque assembly with reliable feed and handling systems.

The Solution

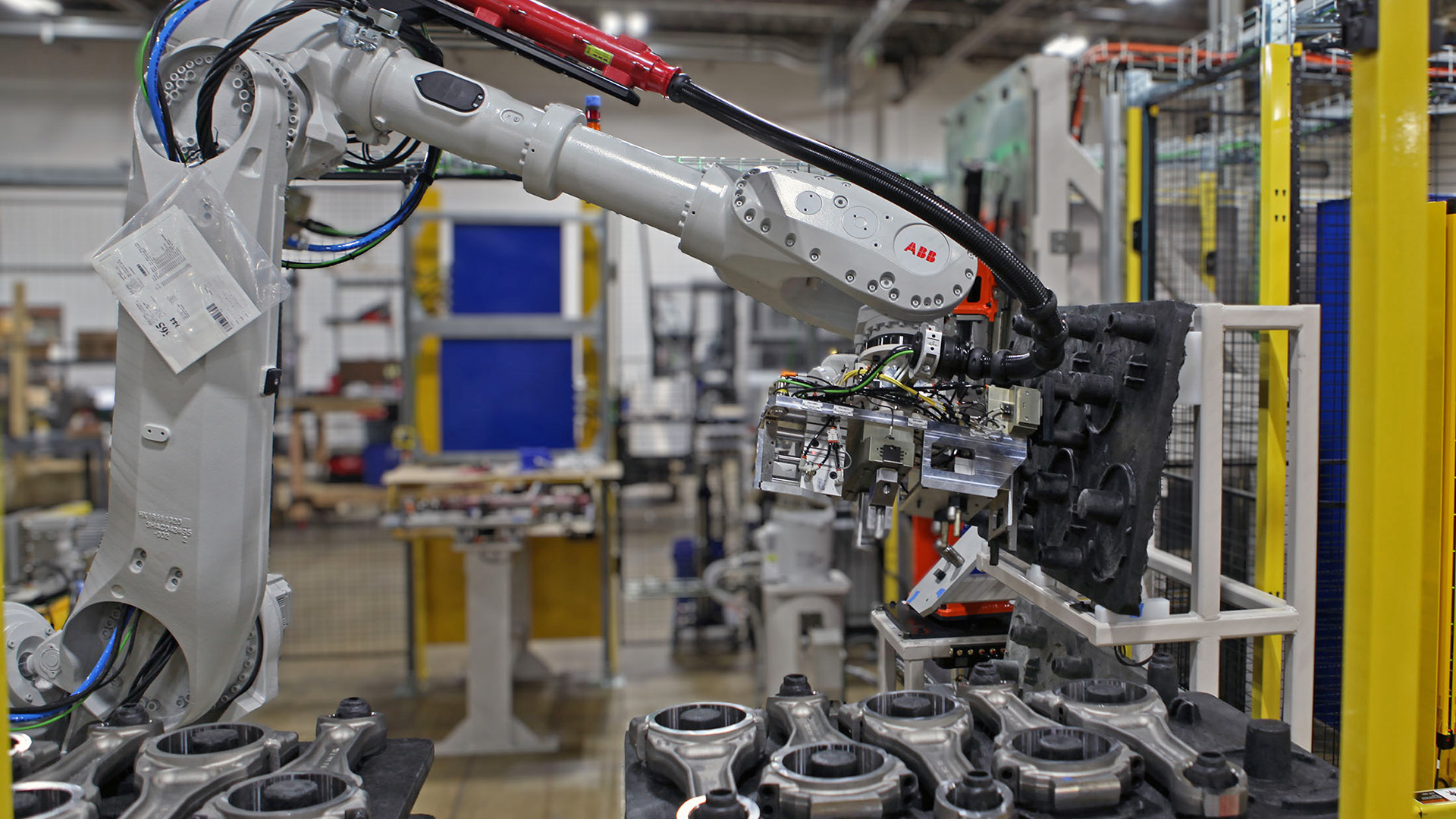

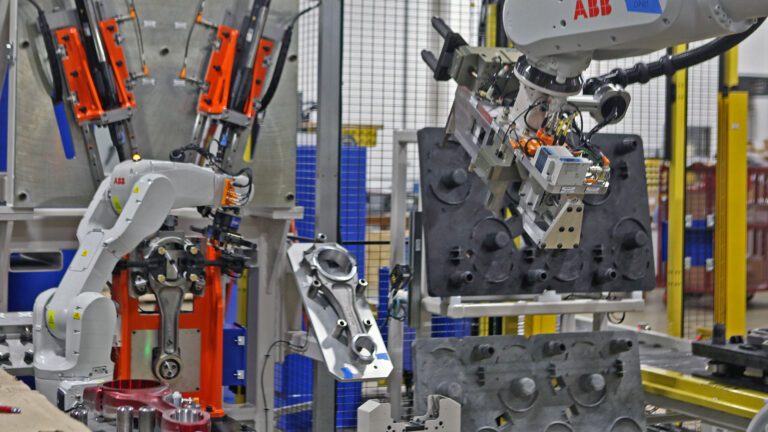

Dual‑Robot Assembly Cell for Bolt Installation, Lube, and Torquing

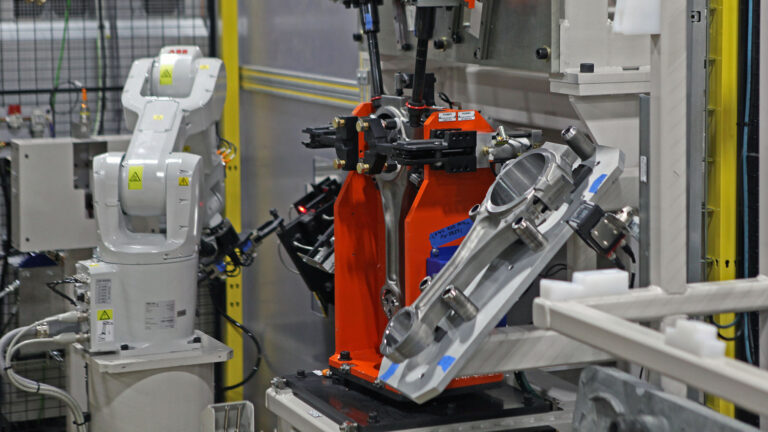

MWES delivered a fully integrated robotic assembly cell featuring:

- ABB IRB6700 robot for loading, transfer, and unloading of connecting rods

- ABB IRB140 robot for precise bolt pickup, lubrication, and placement

- Bolt rundown and final torque application to specified torque targets

- Integration with rod and cap fixturing, conveyors, and V‑block pallets

- Automated removal and replacement of full and empty pallets for continuous operation

An operator places rod blanks and initiates the process via HMI. The system handles all torque application, part transfer, and pallet management—flowing smoothly from infeed to outfeed with minimal operator intervention.

This turnkey cell enables automated, high-precision connecting rod assembly from start to finish.

The Results

85‑Second Cycle Time, Greater Consistency & Reduced Labor Dependency

MWES’s automation delivered significant operational advantages:

- Achieved a consistent 85‑second full‑assembly cycle per rod

- Eliminated variability in bolt torque and rotational alignment

- Reduced manual assembly and rework due to precise automation

- Enabled consistent part quality with lights‑out operational capability

By replacing manual labor with a dual-robot cell, MWES helped the manufacturer achieve scalable, high‑accuracy assembly with lower staffing and higher throughput.