The Challenge

Reducing Manual Labor While Improving Throughput and Safety

This motorcycle manufacturer relied on manual clutch assembly, limiting throughput and introducing ergonomic risk. They required a footprint-efficient solution to:

- Automate assembly of ball ramp clutch components safely

- Support single-operator control while maintaining production rates

- Apply grease, insert ball bearings, and install clips reliably

- Integrate safety features to protect the operator

MWES was selected to provide a turn-key semi-automated assembly system that could augment manual labor without requiring a high degree of worker training.

The Solution

Single‑Operator Turn‑Key Assembly Machine with Indexing & Grease Application

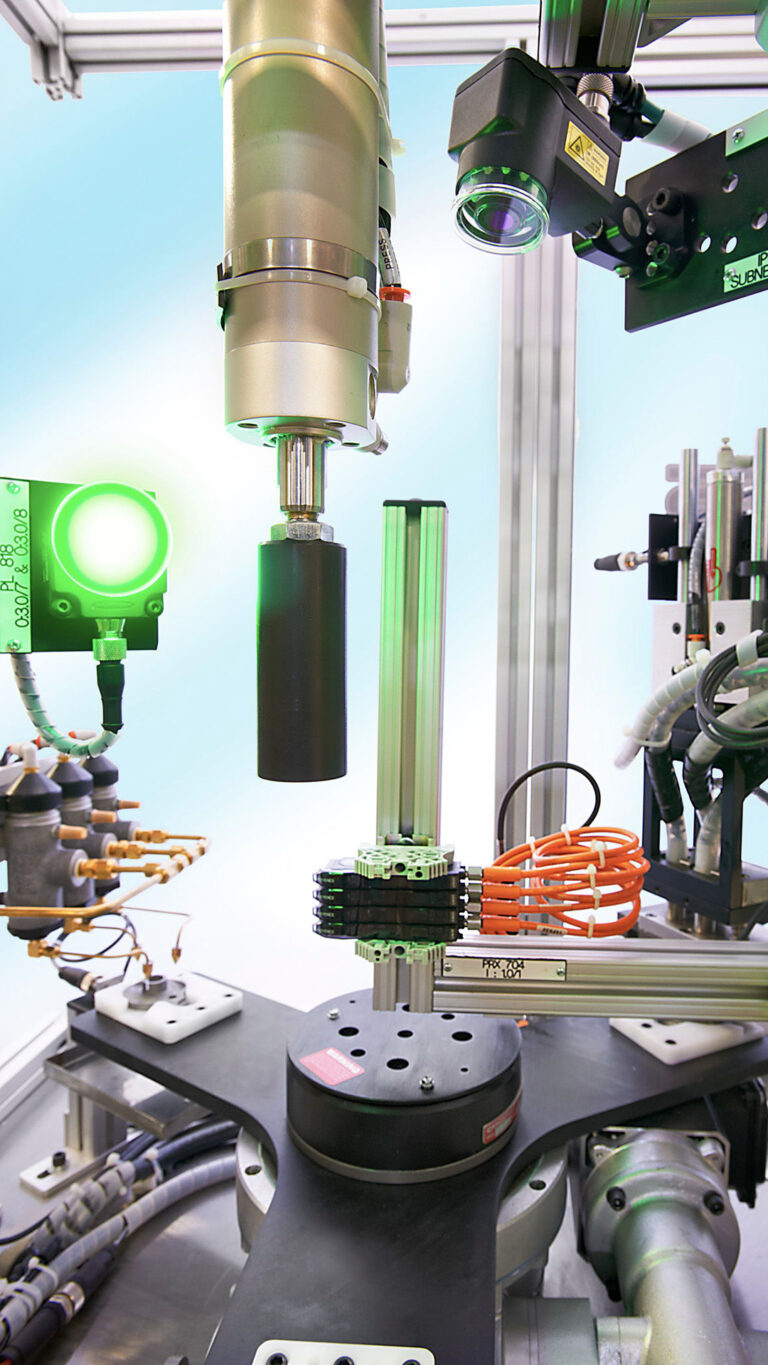

MWES delivered a specialized assembly machine featuring:

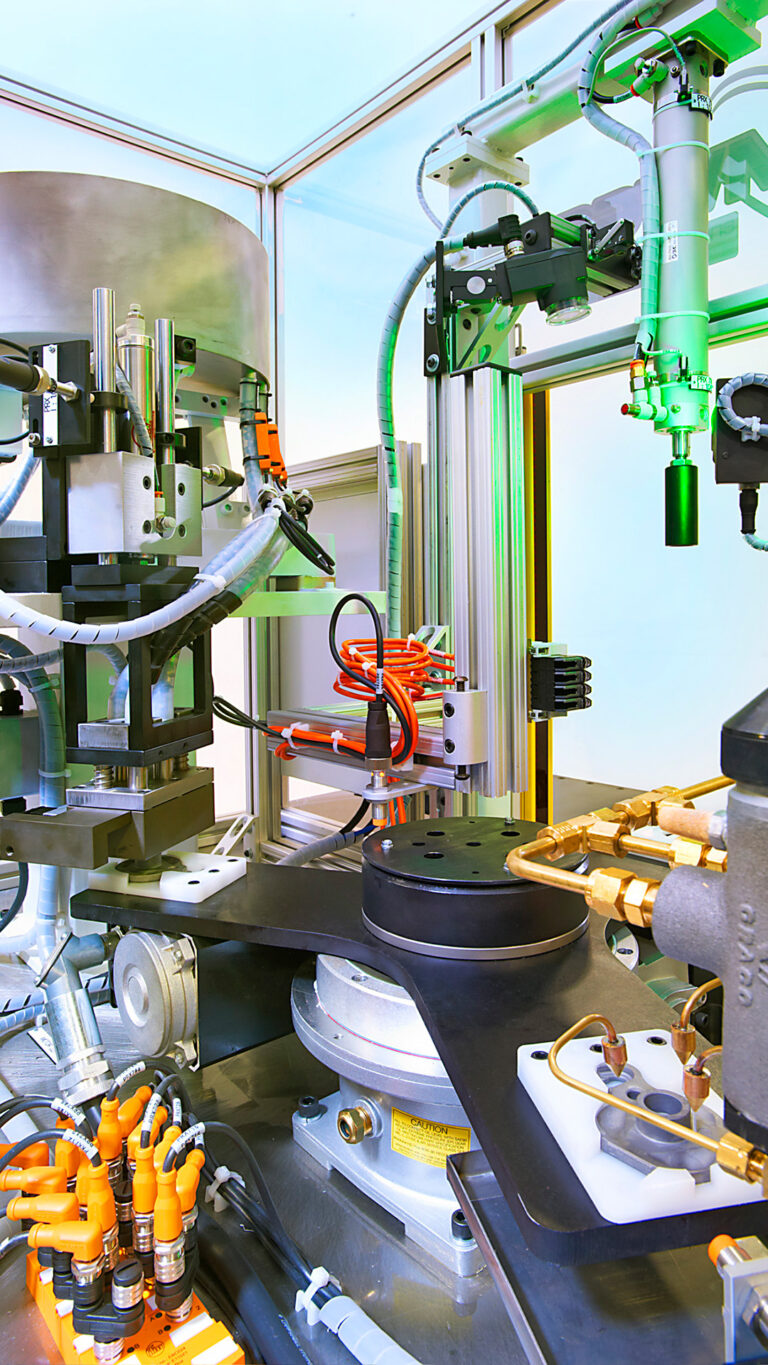

- A three-position indexing dial table that advances each assembly through loading, grease application, ball insertion, and c‑clip pressing stations

- Automatic ball-feeder and grease applicator synchronously loading bearings and grease into lower ramp pockets

- Sensor-based verification and c-clip insertion for secure assembly

- Safety features including light curtain and two-hand control to ensure operator arms are clear during operation

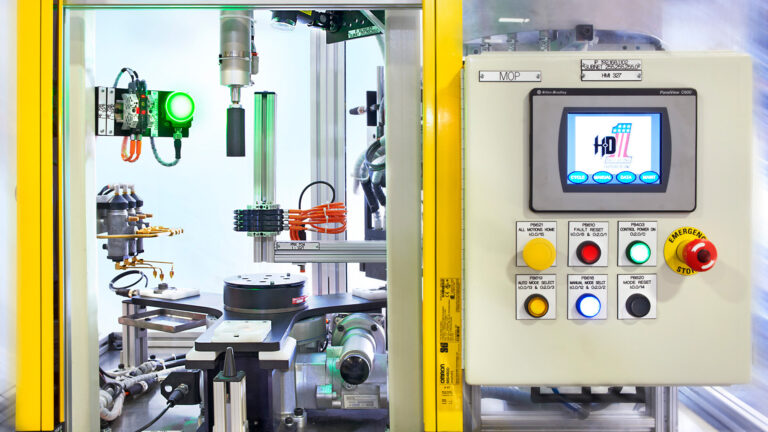

In operation, the operator loads ramp components, starts the cycle via HMI, and removes completed assemblies—enabling reliable production with minimal operator strain.

Summary: This semi-automated unit supports ball and ramp assembly using precision staging, grease application, and clip press—all with built-in operator safeguarding and one-person usability.

The Results

Higher Throughput, Safer Ergonomics & Minimal Labor Dependency

Post-installation improvements included:

- Increased clutch assembly throughput vs fully manual operation

- Maintained existing headcount while reducing physical strain and risk

- Consistent, repeatable quality through automated sequence logic

- Improved operator efficiency—manual component work augmented but not replaced

By combining automation with operator oversight, MWES helped the customer boost productivity, improve safety, and reduce variability—all with a compact and cost-effective footprint.