The Challenge

Precise Machining of Heavy, Long Steel Straps

Machining long steel crane straps manually was time-consuming and prone to misalignment errors. The customer needed a system that could:

- Bore and mill two holes (2″–10″) accurately into straps up to 40′ long

- Automate positioning and machining across variable lengths without multiple changeovers

- Maintain machining accuracy under heavy-tool loads

- Minimize operator effort while maximizing throughput

- Handle steel thicknesses with precision and consistency

- Reduce manual labor and setup time between cycles

The system allows the operator to load fixtures and secure straps with bar knobs, enter part numbers into the controller, and safely trigger the automated boring sequence—minimizing hands-on labor while maximizing repeatability.

This custom automation enables the consistent production of high-quality tailstocks while improving operator ergonomics and safety.

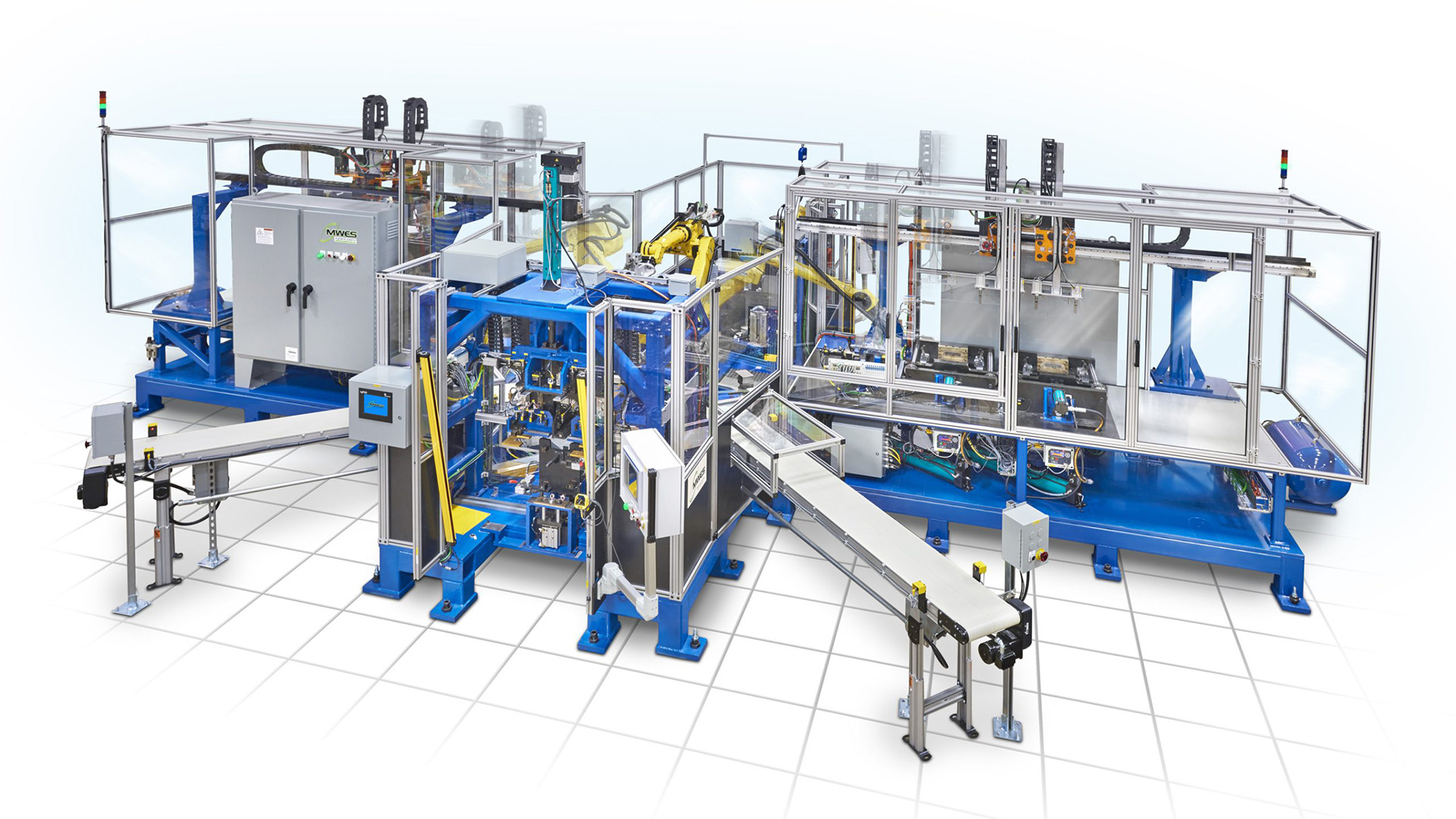

The Solution

Custom 4-Axis Vertical Machining Cell with Automated Positioning

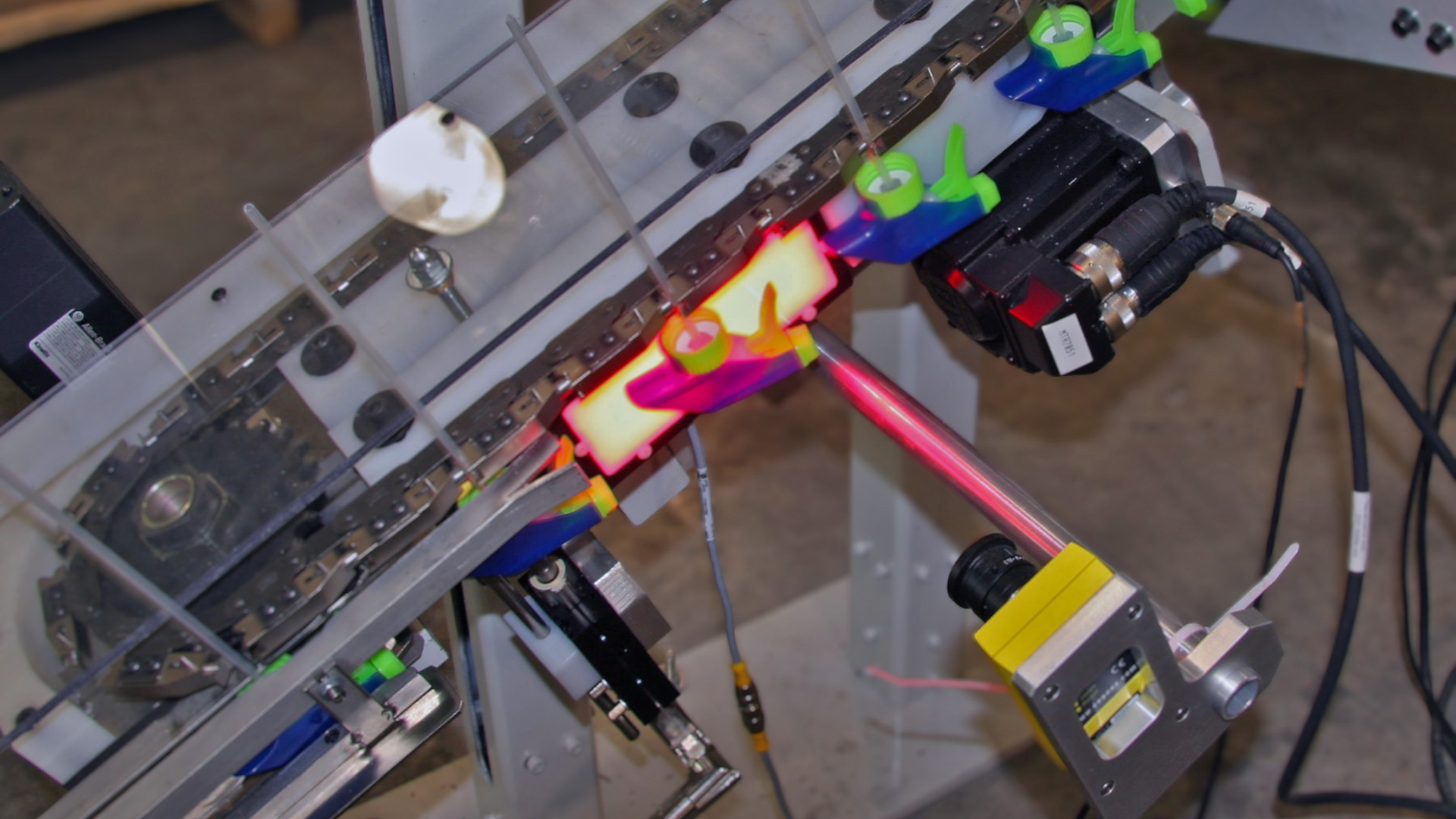

MWES engineered a fully automated machining system featuring:

- 4-axis vertical machining center mounted on a 13.5 m motorized carriage to accommodate strap lengths up to 40′

- Toolpaths for rough milling, high-speed boring, and precision finishing of two holes per strap

- Operator setup via crane-supported fixture loading and CNC start program activation

- Chip-evacuation air valve to clear debris during machining cycles

- Fixture-mounted weldment for secure tailstock positioning

- CNC control system with part-number-based machining programs

The system allows the operator to load fixtures and secure straps with bar knobs, enter part numbers into the controller, and safely trigger the automated boring sequence—minimizing hands-on labor while maximizing repeatability.

This custom automation enables the consistent production of high-quality tailstocks while improving operator ergonomics and safety.

The Results

Consistent Hole Placement, Expanded Capacity & Lower Labor Demand

The automated boring machine delivered measurable performance improvements:

- Achieved precise, repeatable hole milling across 10–40′ straps

- Reduced scrap and rework resulting from manual misalignment

- Enabled consistent, scalable capacity without increasing labor

- Streamlined loading and part setup via fixture-based design

- Reduced operator exposure to steel chips and airborne particles

By automating a previously manual process, MWES helped the customer improve consistency, speed, and flexibility in machining critical crane strap components—all while preserving existing workflow infrastructure.