The Challenge

High‑Volume Spot Welding with Consistent Quality and Minimal Labor

The customer faced several operational challenges that prompted MWES engagement:

- Manual welding introduced variability in weld placement and quality

- Labor shortages and lack of trained welders limited production scalability

- Automotive part tolerances required consistent cyclical welding

- The baffle assembly needed to be completed in under 10 seconds per part

MWES was selected to apply its expertise in resistance-spot welding systems for demanding automotive manufacturing environments.

The Solution

Dual Dial-Table Cell with Automated Spot Welding and Reject Handling

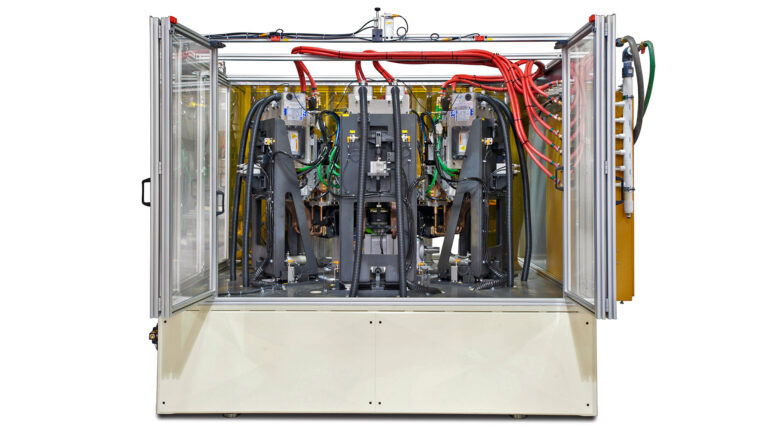

MWES engineered two fully enclosed welding cells that operate in parallel and include:

- Six-station indexing dial systems for both louver and diverter welding modules

- Dual Milco C‑type resistance weld guns at each weld station to apply consistent spot welds

- Fixture-based part holding optimized for accuracy and repeatability

- Integrated pneumatic unloading and reject chutes to manage good and scrap parts

- HMI-based control and automated cycle sequencing to ensure reliable throughput

This spot-welding automation delivers rapid, consistent weld application and reduces operator dependency while maintaining high-volume output.

The Results

One Weld Every Ten Seconds,700K+ Parts Annually, Minimal Labor

Implementation realized substantial performance and quality improvements:

- Capable of welding over 800,000 parts per year, or one complete part every 10 seconds

- Eliminated manual weld labor and associated fatigue or inconsistency

- Achieved high-repeatability weld placement across long production runs

- Seamlessly integrated into existing cell layout without requiring new tooling or infrastructure

By replacing manual spot welding with automated dial-table cells and precision resistive welding, MWES dramatically increased throughput and quality, while minimizing labor involvement.