The Challenge

Tackling Complex Weldments with Limited Welders and Tight Torch Access

Fabricating aerial lift components historically required hard-to-access welds, multiple part rotations, and a workforce of highly skilled welders. The customer needed a scalable automation solution that could:

- Accommodate a variety of aerial lift weldment geometries and sizes

- Ensure ergonomic access to all critical weld locations

- Reduce dependency on manual welders amid rising volume

- Enable continuous operation with minimal changeover burden

MWES was selected to design flexible robotic cells that could meet these production and accessibility demands.

The Solution

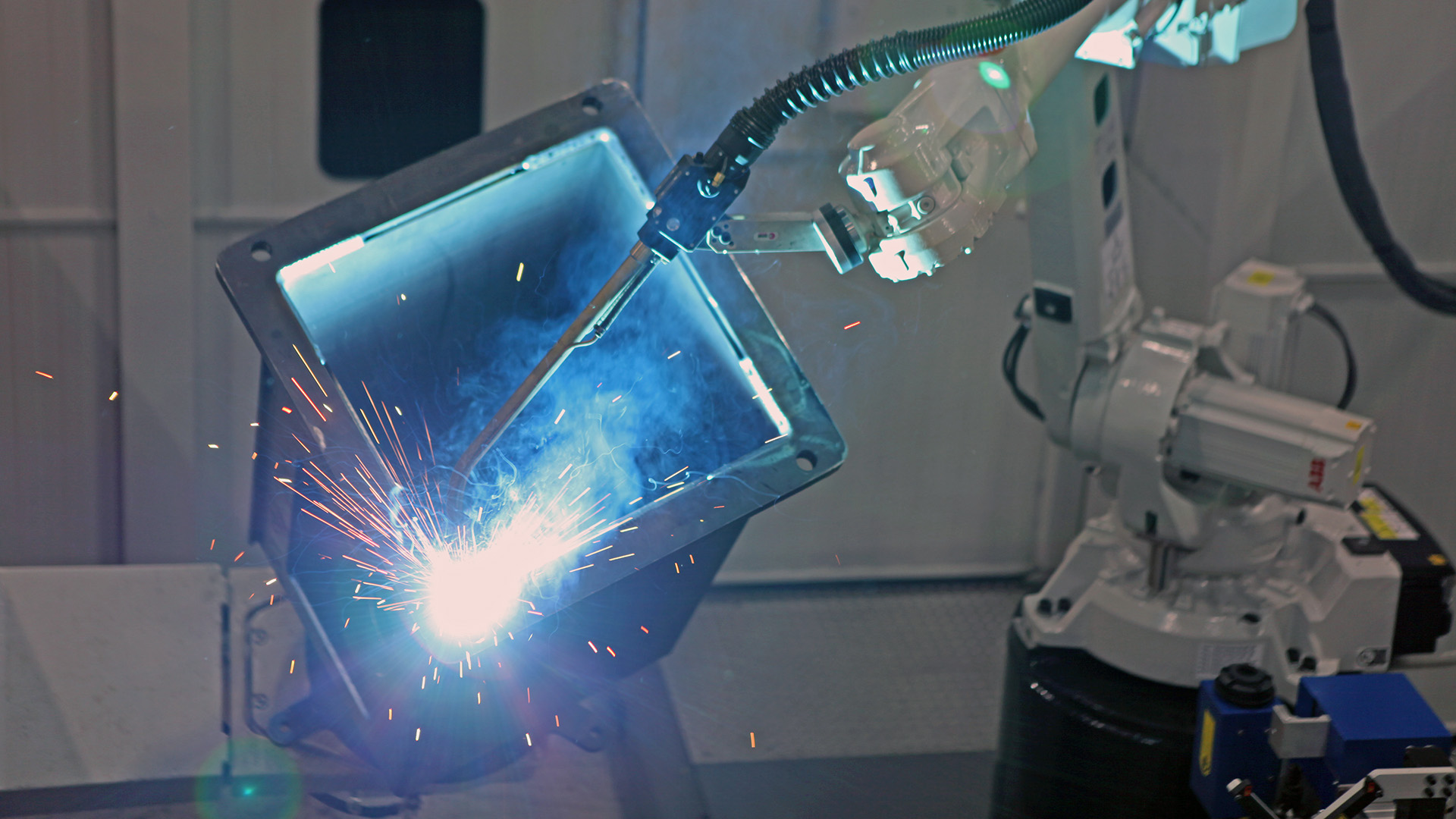

Two Robotic Weld Cells Featuring Servo-Driven Positioners & Track-Mounted Robots

MWES developed two distinct robotic systems tailored to the weldment size and shape:

- Cell 1: Dual-station configuration with two-axis servo-driven positioners at each station, providing total manipulation capability ideal for turret and pedestal weldments

- Cell 2: Single robot on a servo Floortrack paired with a large two-axis positioner—optimized for large outriggers and boom sections requiring broader access

Both cells follow a shared operator workflow: while one station welds, the operator loads or unloads the other. The positioner then indexes the weldment into place and the robot executes its programmed sequence

In summary, MWES delivered two modular robotic cells with dynamic fixturing and workflow design—enabling full parameter flexibility across varying lift weldment geometries.

The Results

Improved Throughput, Reduced Labor, and Consistent Quality Across Weldments

As a result of implementing this automation, the customer experienced:

- Streamlined welding of aerial lift weldments with minimal manual intervention

- Enhanced throughput and weld consistency across varied part sizes

- Elimination of ergonomic strain and access challenges for operators

- Scalable automation which supports production growth without hiring new welders

By combining dual robotic cells with adaptable positioning, MWES enabled safer, faster, and more flexible weld handling for aerial lift components.