The Challenge

Handling Large Vessel Heads Was Labor-Intensive, Inconsistent & Unsafe

Pressure vessel head fabrication demands exact welding quality and safe part handling. Manual approaches involving overhead cranes were slow, risky, and difficult to scale.

- Heavy cylindrical heads required crane operation to position for welding

- Manual welding introduced quality variability and rework

- Labor-intensive processes limited throughput

- Ergonomic and safety concerns from heavy manual handling

MWES was chosen to deliver an ergonomic, scalable, and quality-assured automation solution suited for heavy-duty welding.

The Solution

Multi‑Station Hybrid Cell with Manual Tack & Robotic Finishing

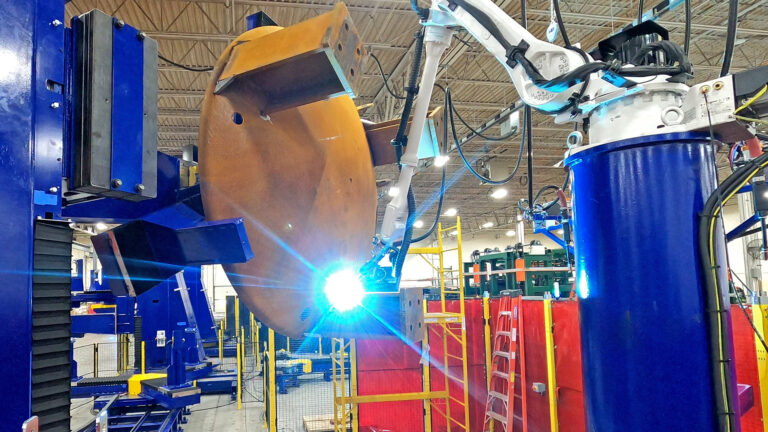

The system includes multiple workstations: two manual-positioner stations for operator tacking and root-pass welding, followed by a robotic weld finish station with integrated transfer tables.

- Large multi-axis weld positioners support varied head geometries across station types

- Manual tack/weld stations accommodate misalignment and operator finishing for root passes

- Robotic finishing cell completes automated weld joints using three industrial robots

- Transfer tables and fixtures move parts through manual tack stations into the robotic cell efficiently

Part data and tooling workflows are coordinated through PLC HMI interfaces and servo positioner logic to support both manual and automated tasks.

The Results

Safer, Higher‑Quality Welding with 40 % Throughput Improvement

The integrated system improved production quality and safety while meeting scale demands without added labor:

- Increased pressure vessel production throughput by 40 %

- Eliminated awkward crane handling and improved operator ergonomics

- Reduced rework through consistent, controlled welding sequences

- Enabled smoother part transfer and cycle alignment across stations

This hybrid automation effectively blended human precision for first-pass welding with robotic speed and consistency, delivering maximum impact for heavy‐part fabrication.