EasyArc™ Welding Software

EasyArc™ Software for Robotic & Cobot Welding

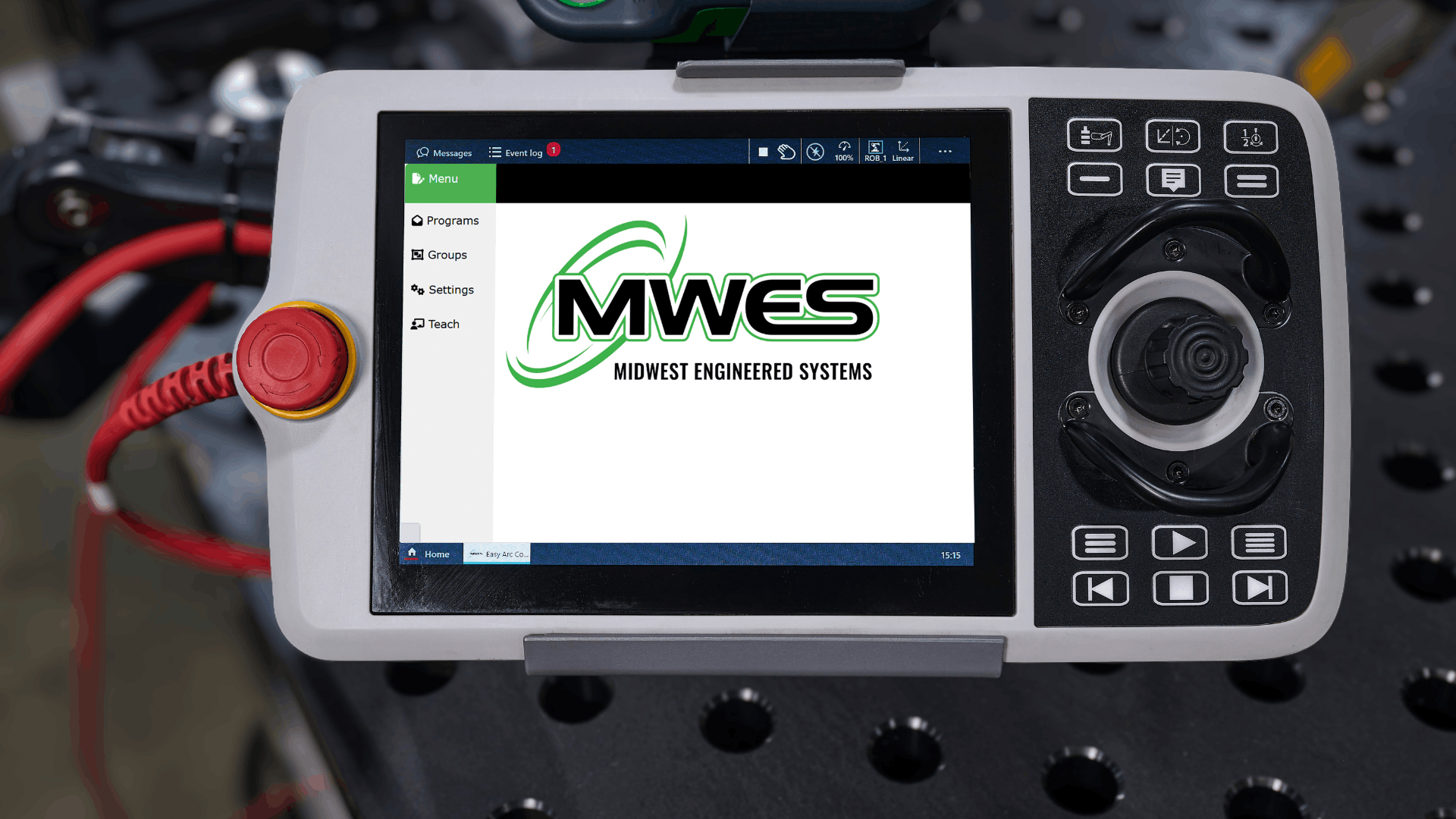

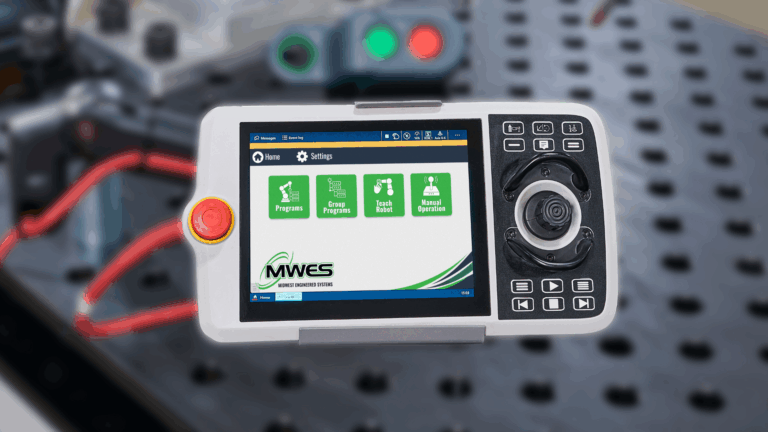

EasyArc was designed specifically for robotic welding and collaborative welding systems, giving manufacturers an easy way to adopt automation without sacrificing precision or flexibility. Operators can set weld paths, adjust parameters, and trigger weld routines using a clean, guided interface built for shop-floor usability.

Key Benefits:

- Simplified robot programming with intuitive menus

- Faster weld setup and changeovers

- Improved weld consistency and repeatability

- Reduced learning curve for new automation users

- Ideal for high-mix, low-volume production environments

Built for Production Welding

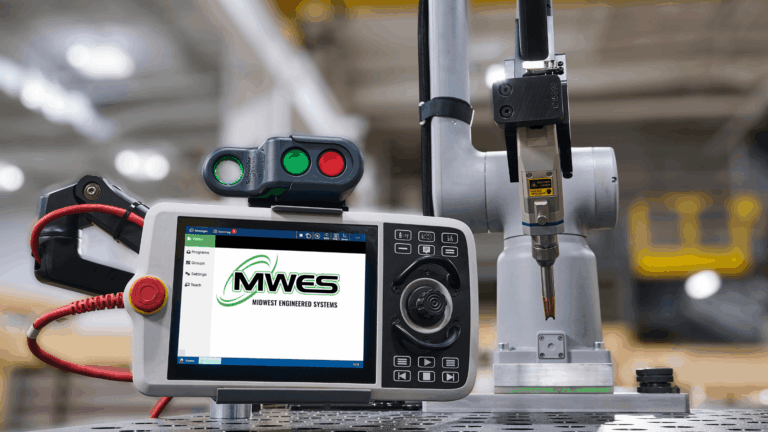

Whether running industrial robotic welding cells or cobot weld carts, EasyArc improves workflow and output quality. The software includes built-in weld path tools, templated routines, and user-friendly adjustment controls — empowering welding operators to run automation confidently and efficiently.

Integration-Ready for MWES Welding Systems

EasyArc is fully integrated into MWES EasyArc™ Cobot Welding Systems and can be configured for custom robotic welding cells. With built-in safety logic, industrial-grade reliability, and process-driven functionality, EasyArc gives manufacturers a scalable foundation for robotic welding adoption.

Why EasyArc Software?

- Purpose-built for welding automation

- Supports cobots and industrial robots

- Enables rapid deployment & operator adoption

- Enhances shop-floor efficiency and weld quality

- Reduces dependency on advanced robot programming skills

EasyArc™ Software gives manufacturers the tools to unlock welding automation — without complexity. Designed by welders and automation experts, it delivers simple programming, consistent results, and fast ROI for robotic and cobot welding.

Contact us to learn how EasyArc can accelerate your welding automation program.