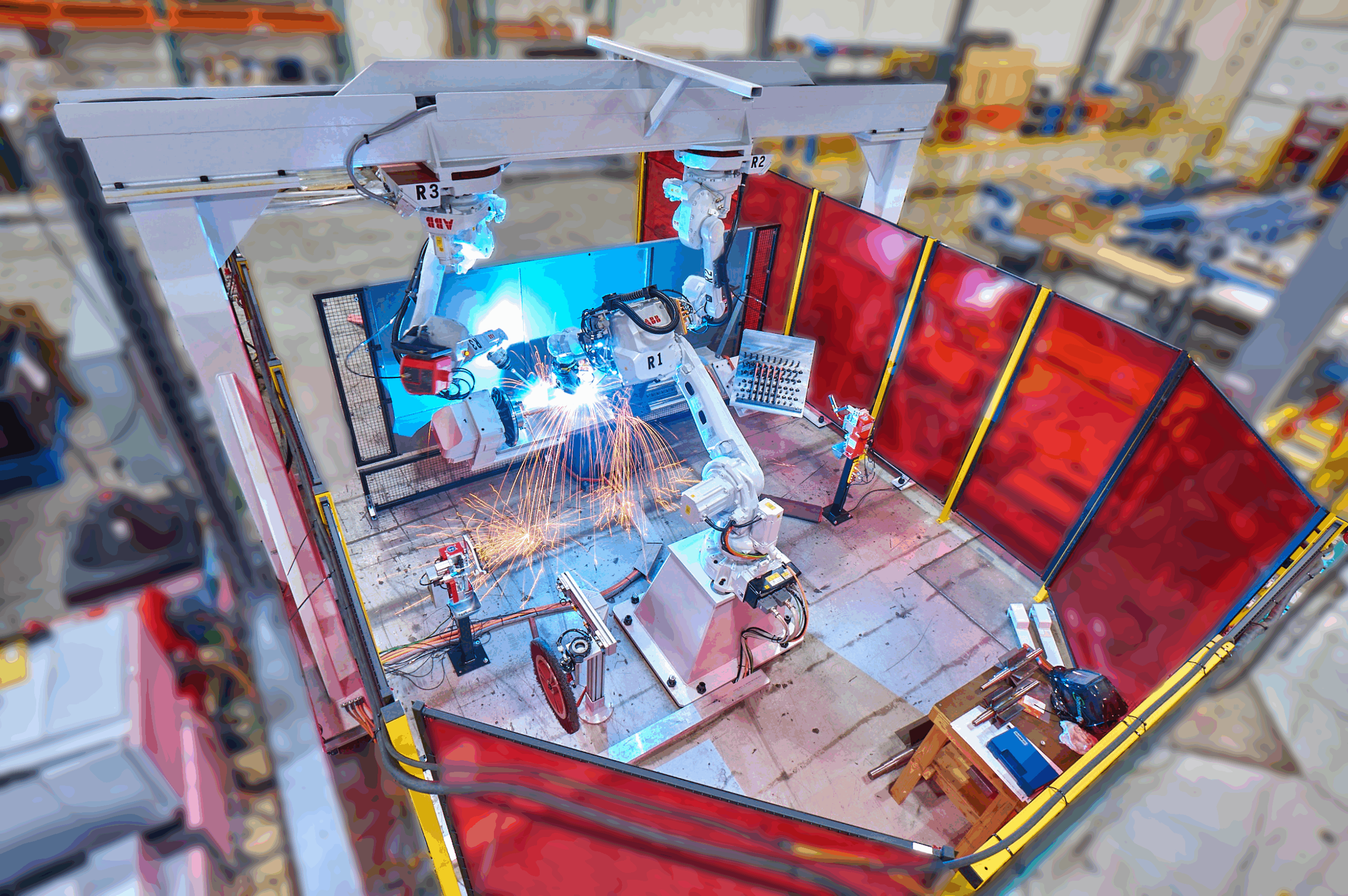

Custom Weld Cells & Fixturing

Easy-Arc Custom Welding Cells

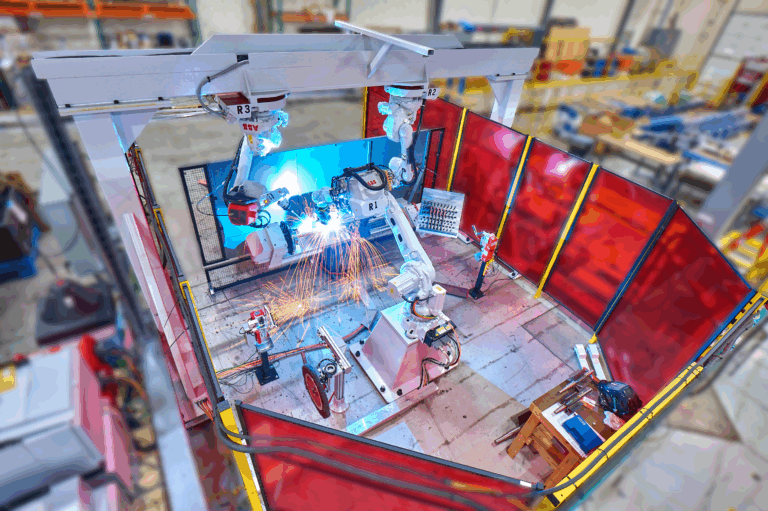

Complex welding challenges require systems built to exact specifications. MWES develops custom robotic welding cells tailored to complex and high-mix manufacturing environments. We engineer welding solutions that deliver consistency, eliminate production bottlenecks, and reduce reliance on scarce skilled labor.

Advantages of Automated Welding Cells:

- Consistent, repeatable weld quality

- Increased production efficiency and uptime

- Reduced need for specialized manual welders

- Enhanced operator safety and ergonomics

Our Weld Cell Expertise

MWES has delivered complete, turnkey welding systems for diverse industries, incorporating advanced technologies such as laser welding, robotic vision, adaptive welding, and material handling. Our designs minimize heat distortion, improve weld quality, and accommodate even the most complex geometries.

With over 30 years of experience, we know what works, what doesn’t, and how to refine solutions for maximum performance. Each custom weld cell we build is informed by our decades of successful integrations.

Welding Fixtures & Tooling

No welding automation project is complete without fixturing. MWES designs custom welding fixtures that ensure precise part positioning and alignment during robotic welding operations. Proper fixturing is essential for maintaining part tolerances, improving weld repeatability, and reducing rework. Each fixture is engineered for your process and can be powered hydraulically, pneumatically, or via servo actuation for ultimate control and speed.

Types of Welding Fixtures:

- Hydraulic Fixtures – Deliver strong, distortion-free clamping for heavy weldments.

- Pneumatic Fixtures – Air-powered systems ideal for high-speed, repetitive welding.

- Manual Fixtures – Ergonomic and flexible for skilled welders and hybrid workflows.

Our engineering team evaluates each process to determine the best fixture solution, maximizing efficiency, safety, and reliability.

Proven MWES Welding Automation Solutions

Our solutions are tailored to customer requirements, with proven results across industries:

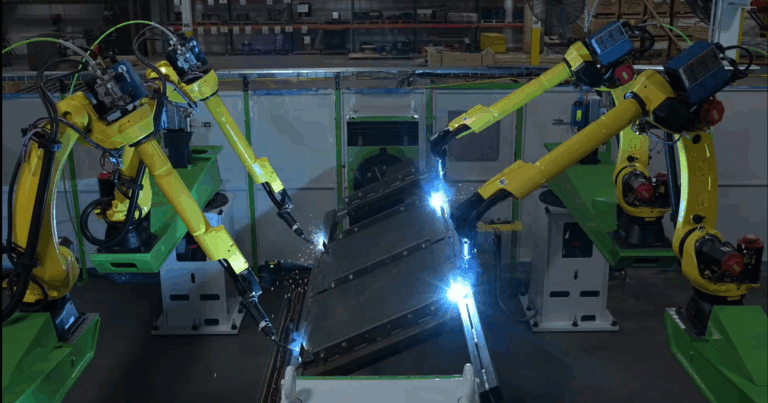

- Robotic Welding & Positioner System – Integrated into a conveyor system to automate tack-welded assemblies.

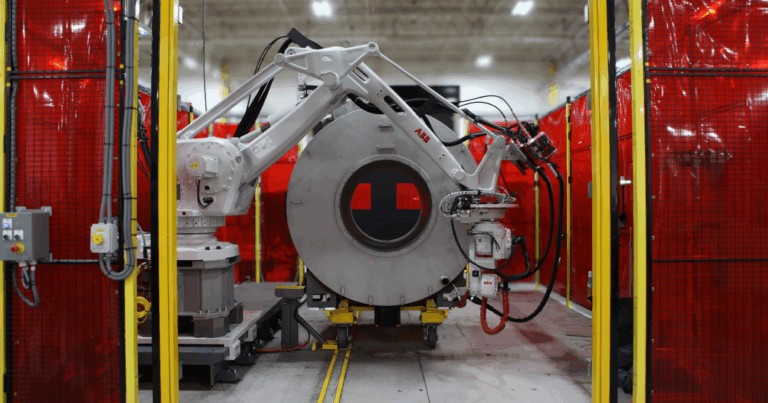

- Pressure Vessel Head Welding Cell – Combined manual and robotic welding stations for head assemblies.

- Concrete Mixer Drum Welding Cell – Automated welding of sub-assemblies using Skyhook Positioners.

- Automated 3-Piece Pipe Weld Cell – Freed manufacturers from labor shortages by automating pipe welding.

Our Welding Automation Expertise

As a certified robotic integrator, MWES combines mechanical design, controls engineering, and programming expertise to deliver complete automated welding systems. Our robotic weld cells integrate vision guidance, adaptive controls, and advanced material handling—reducing distortion, improving accuracy, and increasing manufacturing efficiency.

From fixturing to full-scale robotic automation, MWES builds custom welding solutions that deliver precision, consistency, and performance. Whether you need to automate a single station or an entire line, our engineers can design and integrate a system tailored to your operation.

Contact our team to explore how MWES can transform your welding process with automation.