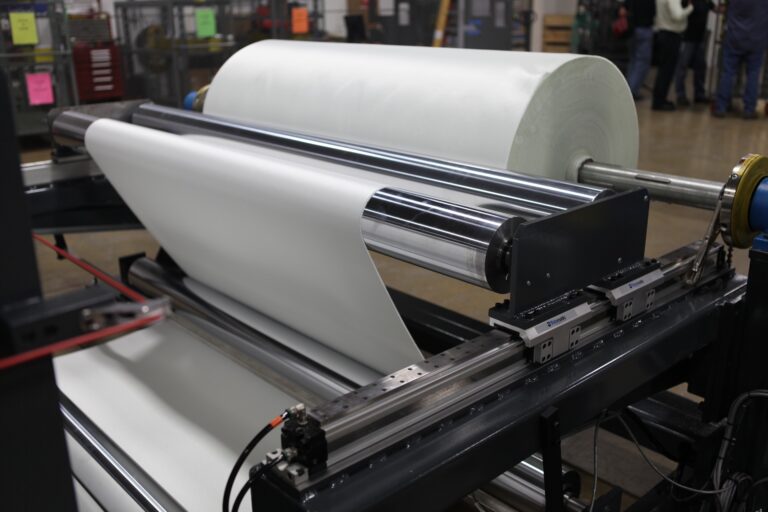

Unwinds and Rewinds

Engineered for Consistent Tension and Control

Effective unwinding and rewinding are essential for maintaining web quality. Midwest Engineered Systems’ systems are designed to ensure constant web tension, regardless of roll diameter, speed, or material type. Using dancer rolls, load cells, or closed-loop drive control, our unwind and rewind modules maintain precise tension isolation between process zones—minimizing defects such as wrinkling, telescoping, or gauge variation

Flexible Unwind & Rewind Configurations

MWES offers a wide range of unwind and rewind designs to match your operation’s layout, speed, and roll requirements:

- Shafted or Shaftless Unwinds for secure roll holding and quick changeovers

- Single-Position, Dual, or Turret Designs for continuous or roll-to-roll operation

- Driven or Braked Unwinds for adjustable web tension control

- Automatic Splicing Systems for uninterrupted web transfer

- Core or Surface Rewind Systems to handle a range of materials and roll diameters

- Edge Guiding and Web Alignment Systems for precise lateral positioning

Built for Stability, Safety & Integration

Every MWES unwind and rewind system is engineered for stability and smooth web conveyance. Our designs incorporate proper roller geometry, critical speed balancing, and low-inertia materials such as anodized aluminum or carbon fiber to reduce drag and vibration. Safety features such as guarding, automatic roll handling, and torque-limited drive systems ensure operator protection and long-term reliability.

Whether you’re processing delicate films or heavy-gauge laminates, MWES provides reliable, precision-engineered unwind and rewind systems that keep your web running straight, smooth, and stable. Partner with us to upgrade your line performance and roll quality.