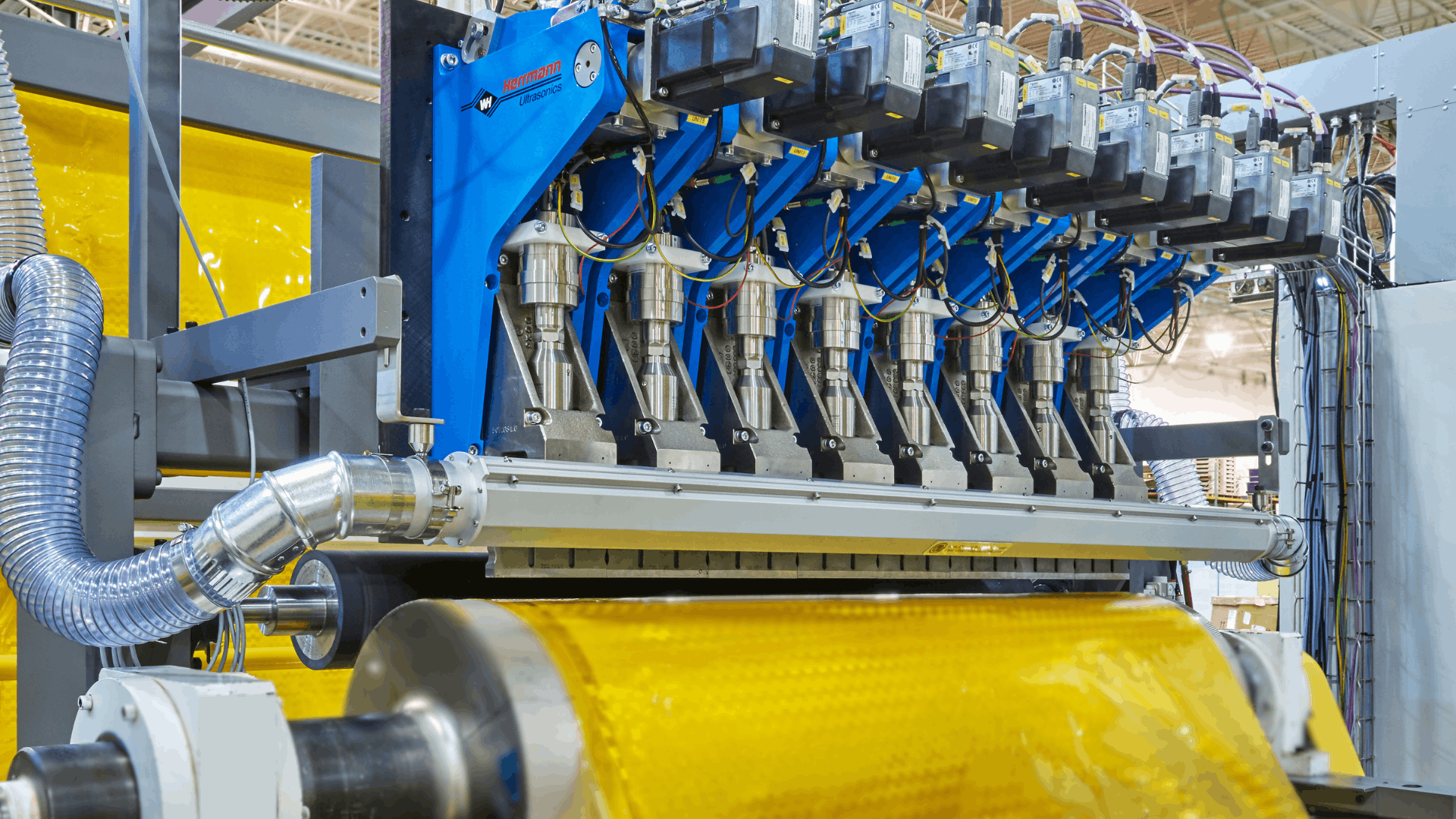

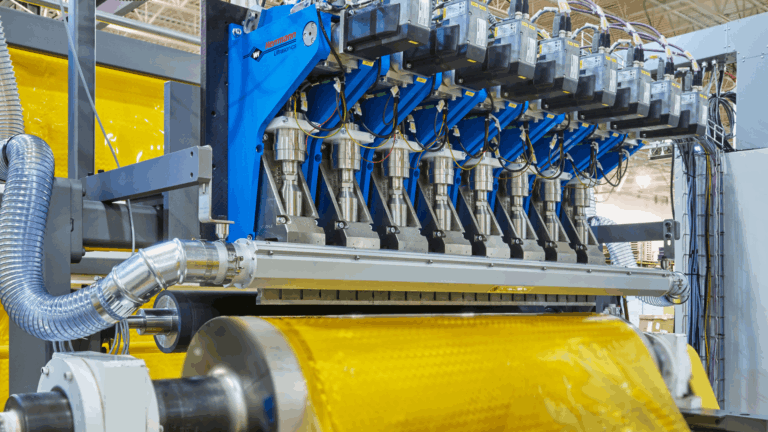

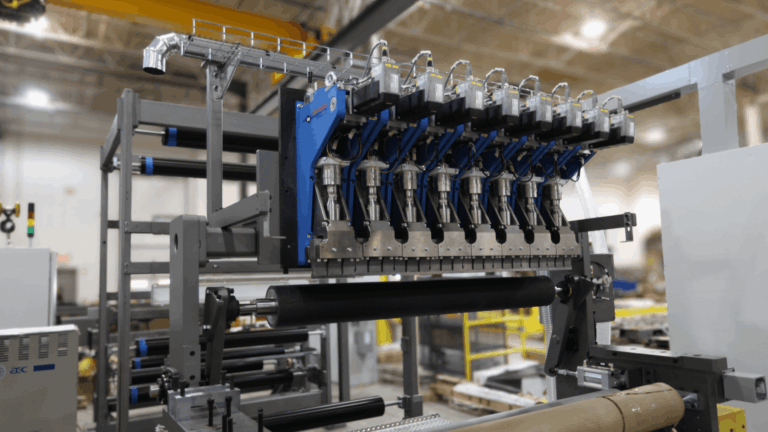

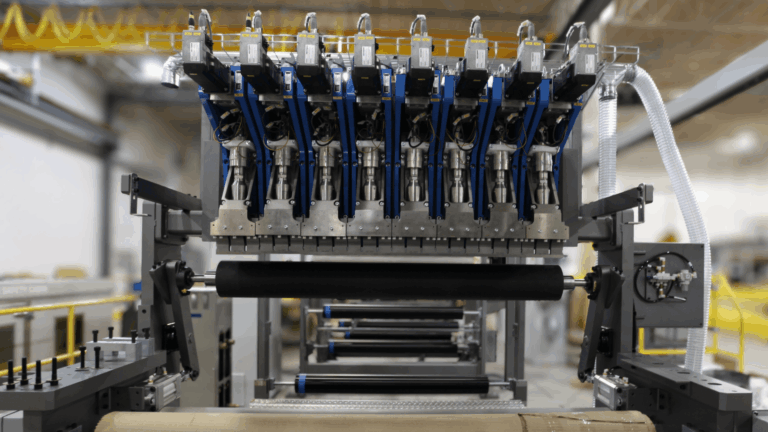

Ultrasonic Welding

High-Precision Welding for Web and Part Applications

Ultrasonic welding offers a clean, efficient alternative to traditional bonding methods by creating molecular-level joins through vibration and pressure. MWES engineers systems for a wide range of applications, from web-based sealing and fabric bonding to part joining and assembly. Each system is tuned for your specific material thickness, geometry, and production speed—ensuring consistent results and minimal material stress.

Benefits of Ultrasonic Welding Technology

- Clean and Precise Welds: No adhesives, consumables, or contamination

- Fast Cycle Times: Instant bond formation for high-throughput operations

- Energy Efficient: Uses focused vibration energy only where needed

- Strong, Repeatable Bonds: Consistent weld quality across production runs

- Low Maintenance: Minimal tooling wear and fast setup changes

MWES Ultrasonic Welding Capabilities

Our team designs complete ultrasonic welding solutions tailored to your operation, including:

- Continuous and spot-welding systems for plastic webs

- Ultrasonic sealing and edge-trimming stations

- Integration with existing converting or assembly lines

- Automated part handling and weld inspection options

- Custom tooling and frequency tuning for specific materials

Whether you’re welding thin films, filter materials, or rigid thermoplastic parts, MWES delivers precision-engineered ultrasonic systems that improve quality, reduce waste, and boost productivity. Partner with us to bring high-speed, high-strength ultrasonic welding to your production process.