Equipment Retrofits & Upgrades

Many production lines operate on durable but aging equipment. MWES upgrades help bridge the gap—bringing older systems up to today’s performance and safety standards. Our engineering teams assess mechanical and control systems, identifying areas where new technology can improve throughput, web quality, and operator usability.

MWES offers a range of modernization services tailored to your process, including:

Typical System Upgrades Capabilities

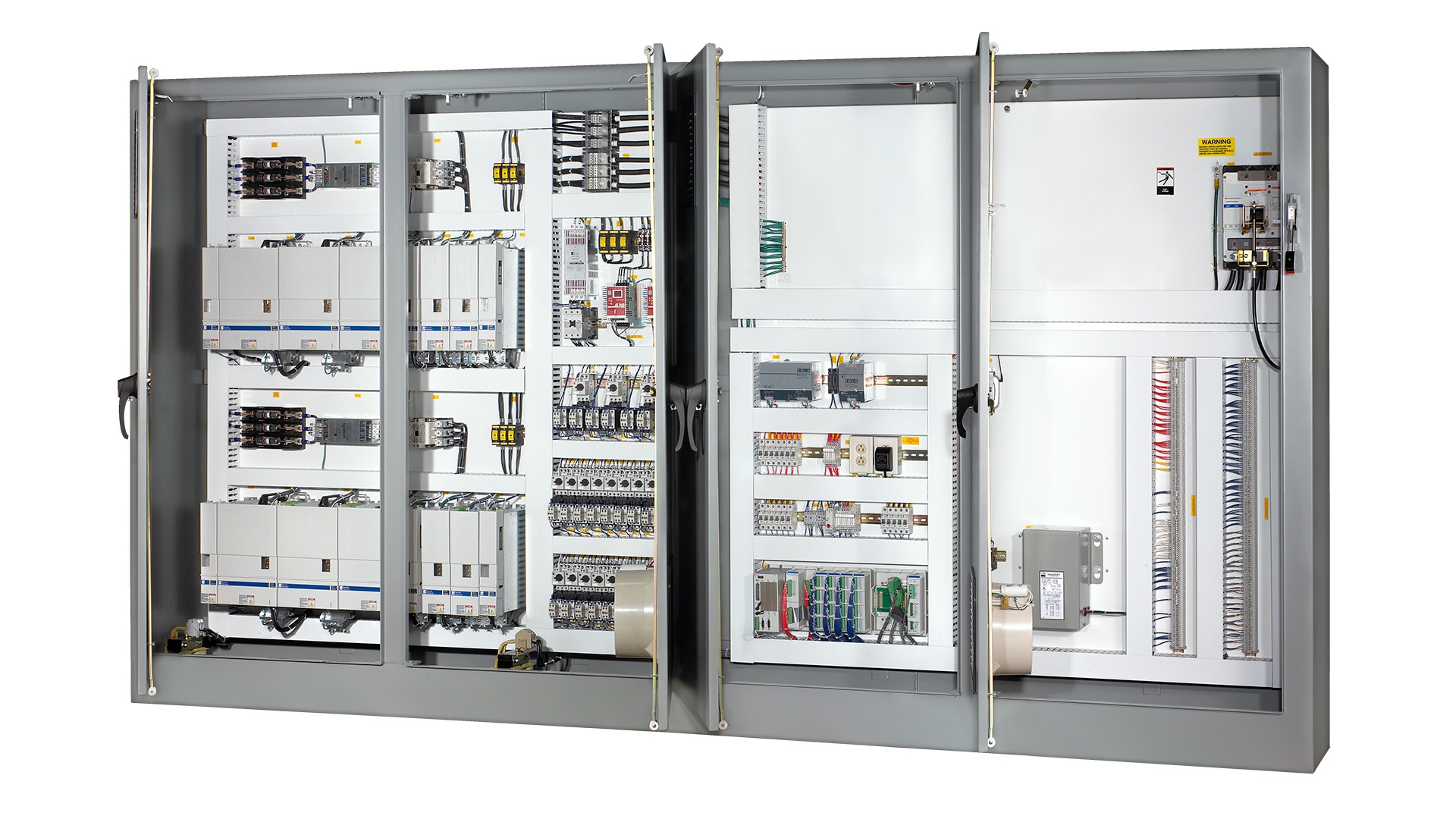

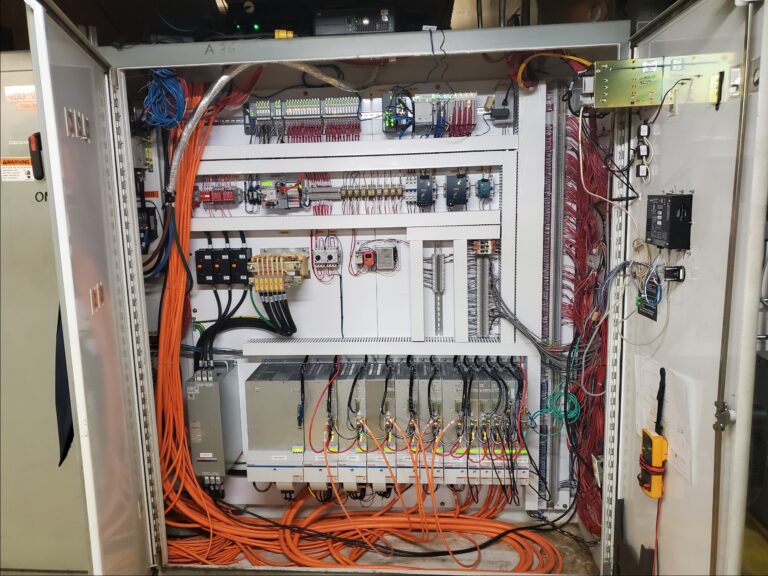

Controls & Drives

- PLC, HMI, and servo drive integration

- Drive system conversions and tuning

- Control configuration updates

- Replacement of obsolete hardware and components

- Software and programming upgrades

- System modernization and re-engineering

Mechanical & Performance Upgrades

- Tension control and dancer system enhancements

- Precision web guiding and alignment improvements

- Roll handling and splicing system retrofits

- Mechanical refurbishment and roller replacement

- Machine component upgrades and modifications

- Line speed and throughput improvements

Safety & Integration

- Safety and guarding updates to meet current standards

- Equipment relocation and reinstallation

- Full factory automation system integration

- Performance optimization and ROI extension

Benefits of Retrofitting with MWES

Our upgrade approach ensures your production system performs like new—often with a shorter lead time and lower cost than replacement. Benefits include:

- Increased throughput and uptime

- Improved web tension stability and product consistency

- Reduced maintenance and spare parts costs

- Enhanced operator control and safety compliance

- Extended equipment lifespan and ROI

From control retrofits to full mechanical rebuilds, MWES combines decades of converting experience with cutting-edge engineering to deliver reliable, high-performance upgrades.

Partner with us to bring new life and next-level capability to your existing web handling equipment.