Standard Automation Solutions

Standard Palletizer Cell

Fast, Flexible Palletizing

This pre-engineered robotic cell is designed for quick deployment and efficient stacking of cases, totes, or bags onto pallets. It’s ideal for manufacturers seeking to automate end-of-line packaging without the lead time of a custom solution.

Key Features:

- Industrial-grade 6-axis robot

- End-of-arm tooling for case, bag, or tote handling

- Safety fencing with interlocked doors

- User-friendly touchscreen HMI

- Programmable pallet configurations

- Compact frame for easy floor integration

Typical Specs:

- Up to 15 picks per minute (depending on product size/weight)

- Handles standard pallet sizes GMA, Block, and CHEP

- Supports multiple SKU palletizing

- Optional pallet dispenser and slip sheet system

- Configurable for one or two pallet stations

- Designed for 24/7 industrial environments

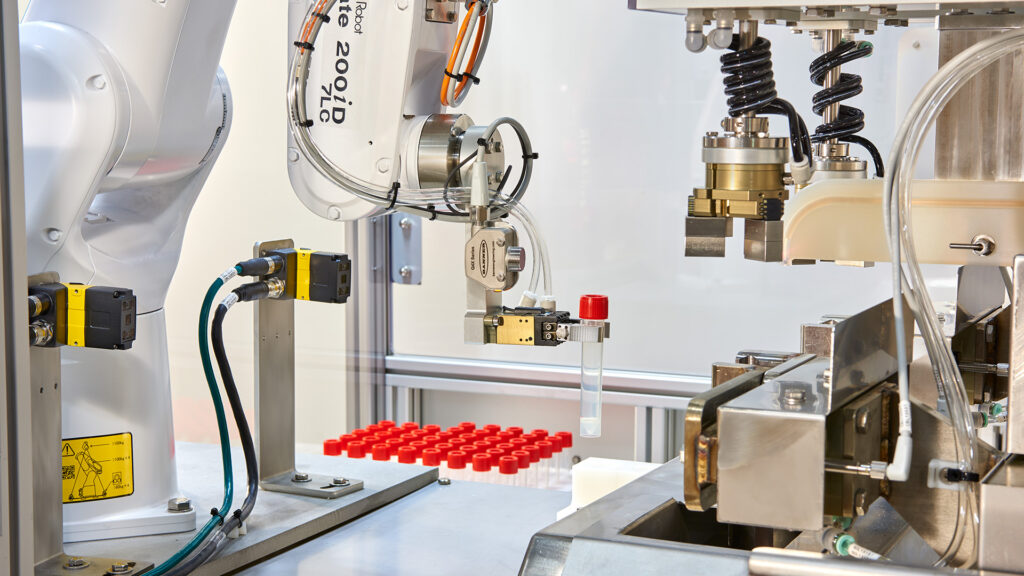

Standard Vial Filling Machine

Vial Filling Built for Precision, Speed, and Sterility

Our standard vial filling machine automates the precise filling and capping of vials in pharmaceutical and laboratory environments. Designed to minimize contamination risk and maximize throughput, this turnkey solution is ready for rapid deployment. MWES can also integrate several other additional options to meet your operational needs, such as vial labeling, automated closure methods, and additional quality control operations.

Included Features:

- Processes up to 17 parts per minute (1,028 parts per hour)

- Exposure time of 5 seconds between vial opening and securing the cap

- Configurable for vials, syringes, T-flasks, bottles or cell-culture dishes

- Handles press-fit, screw cap and crimp close containers

- Safe ISO-5 clean room rated 304 non-passivated stainless-steel enclosure

- FANUC LR Mate 200iD/7LC 6-axis Robot with IP67 protection and force sensing gripper

- Touch-screen color HMI with Estop push button

- R-30iB Mate Plus Controller and teach pendant with Estop

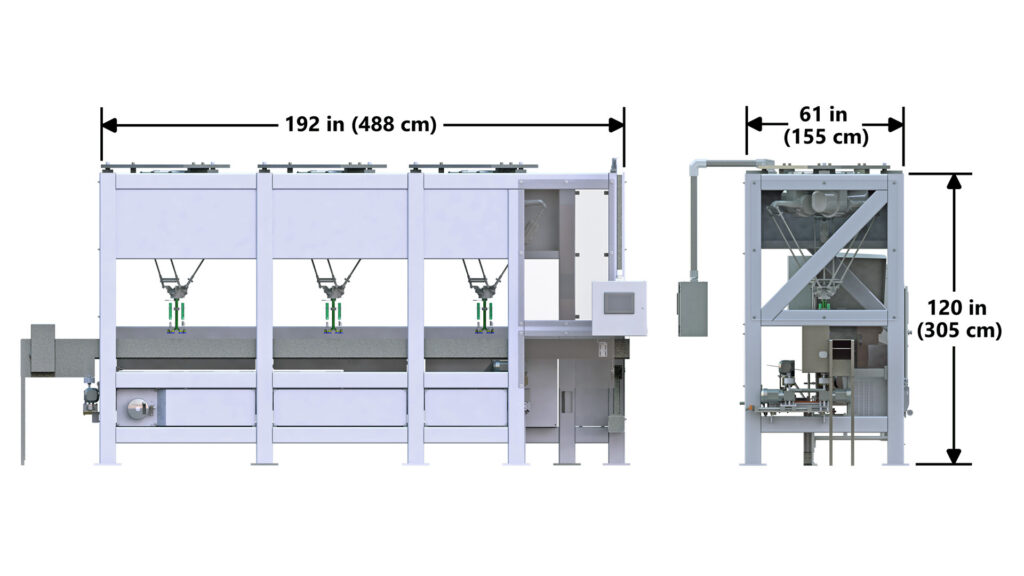

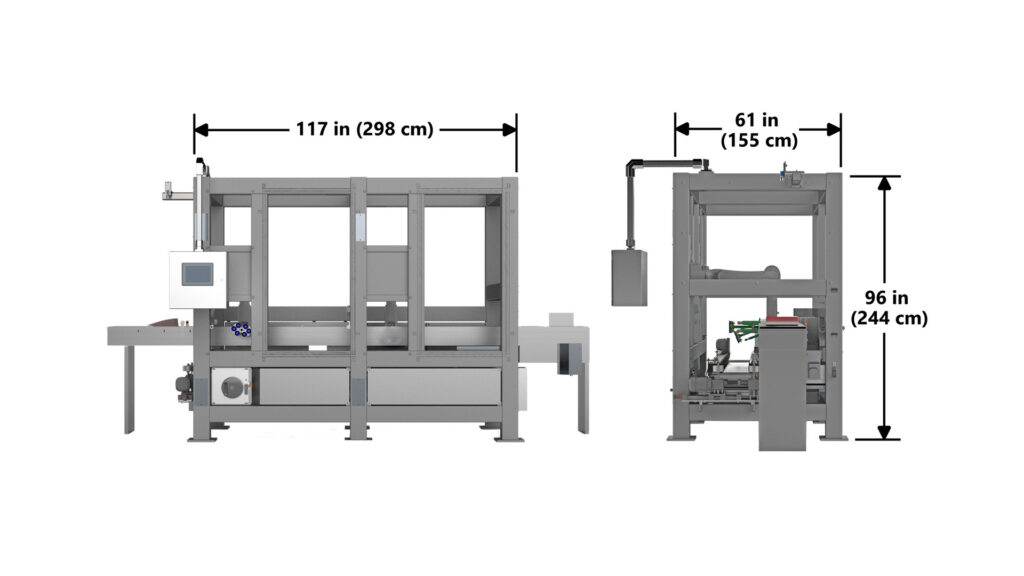

Standard Case Packing Machine

Modernize Operations with Two- and Three-Robot Packing Machines

A compact, high-performance system for efficient case packing automation designed to fit seamlessly into existing operations to increase throughput and reduce worker burnout.

Key Features:

- Ideal for medium to high-speed case packing applications

- Compact footprint saves floor space

- Integrated with a Fanuc robot for precise and repeatable motion

- Designed for efficient packing of a variety of products into cases

- Three robot system can fill 120-160 packages per minute

Standard Specs:

- Adjustable to handle different case sizes

- Includes robotic arm, infeed conveyor, and case presentation system

- Built-in safety enclosure

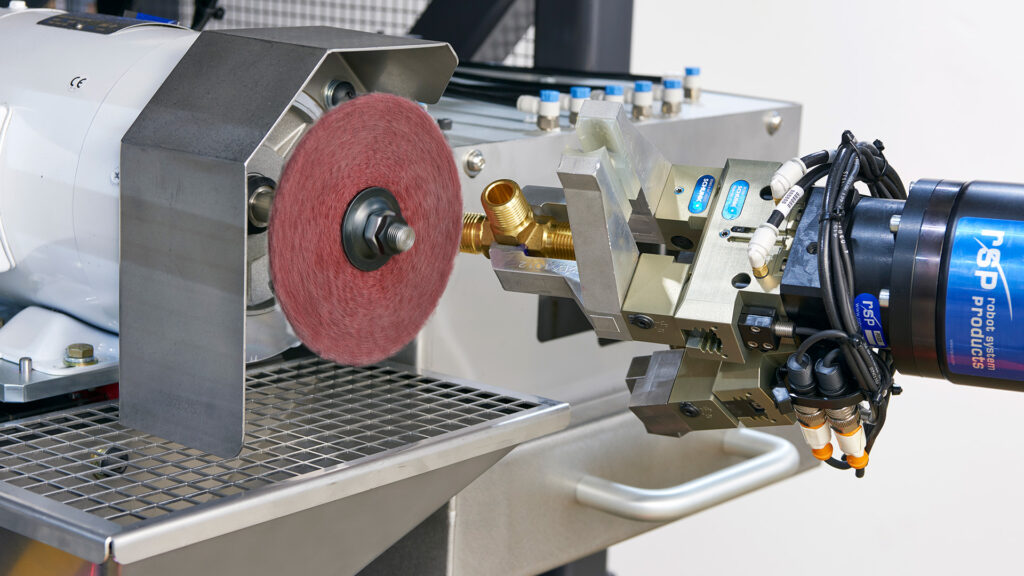

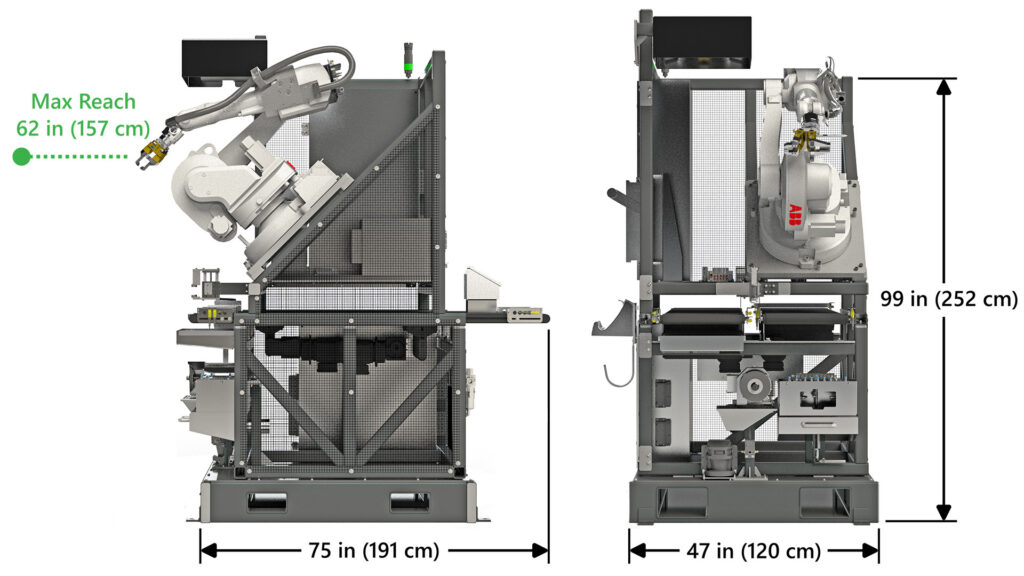

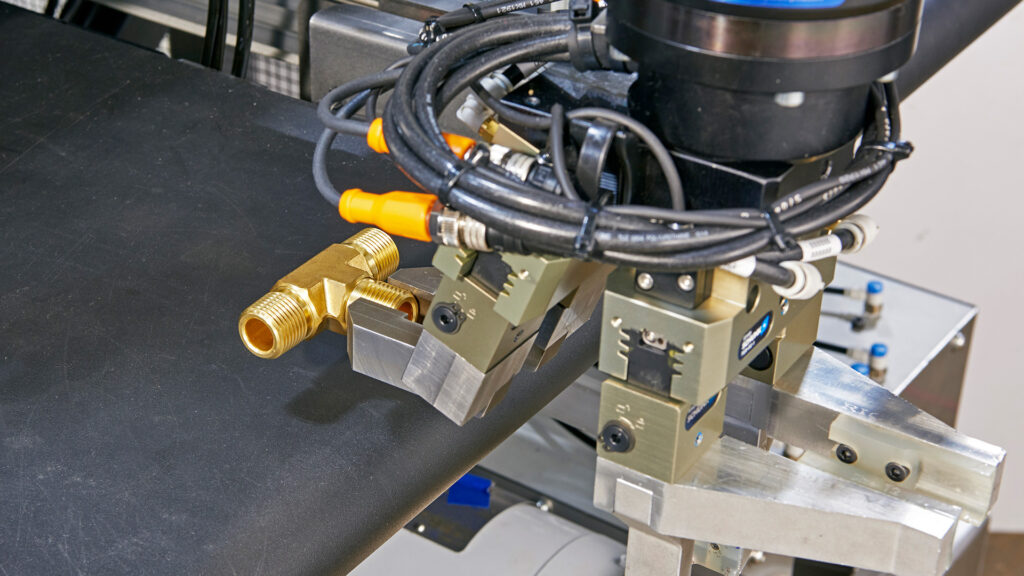

Standard Machine Tending Systems

Reliable, Pre-Built Machine Tending for CNC Operations

A compact, ready-to-run robotic cell designed to load and unload parts from lathes, mills, or other CNC machines. Built for flexibility, repeatability, and safe operation.

Included Features:

- ABB IRB1600ID robot with IRC5 controller

- Pneumatic dual-gripper EOAT

- Steel base with forklift pockets for system movement

- Infeed & outfeed conveyors

- Machine vision camera system

- Motor-driven softwheel deburr in enclosure

- Blow-off nozzles

Typical Options:

- Footprint: Approx. 5′ x 3.5’ x 8′ (varies by model)

- Max reach: 62”

- HMI touch screen

- With and without conveyor

- Slip sheets

- Picking: single case or row forming

- Vacuum, clamp, fork

Standard Welding Systems

Weld Smarter with a Pre-Engineered System

Our standard robotic welding cell delivers consistent, high-quality welds in a ready-to-deploy package. Designed and built in-house, this solution streamlines your operations with repeatable performance, reduced labor costs, and minimal setup time—so you can start producing faster.

Included features:

- Pre-engineered robotic welding cell

- Integrated safety features and guarding

- Flexible configuration for a variety of part sizes

- In-house mechanical and controls design

- Quick installation and start-up support

System Advantages:

- Increased weld precision and repeatability

- Faster cycle times and improved throughput

- Reduced rework and labor demands

- Enhanced operator safety

Included in Every Standard System

Why Choose a Standard System?

Pre-engineered systems from MWES are ideal for businesses looking to automate common processes without the time or cost of building a custom solution from scratch. Designed by experts, each system is built to deliver consistent performance across a variety of industries and applications.

Benefits at a glance:

- Faster lead times

- Lower engineering and integration costs

- Proven, production-ready performance

- Easily configurable for different products or environments

Need Something Custom?

We can tailor each solution to your product size, speed requirements, or factory layout.