Standard Arc Weld Cells

Why Standard Arc Weld Cells?

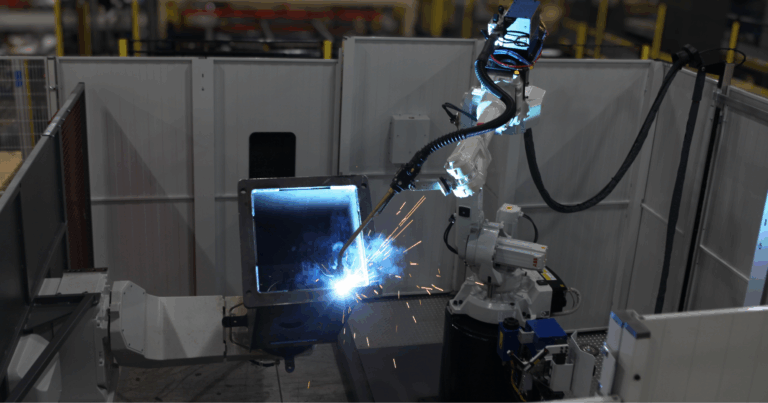

Standard Arc Weld Cells offer manufacturers a flexible, turnkey welding automation solution. By combining advanced robotics with indexing tables and multi-axis positioners, they enable nonstop production. These systems improve throughput, ensure repeatable accuracy, and create safer work environments—all while lowering dependency on manual welding labor.

Types of MWES Standard Arc Weld Cells

Indexing 2-Axis Positioner Weld Cell

This system features a two-station design with rotation and tilt axes, up to two robots, and load capacities up to 1,700 lbs. While one station welds, the other is used for loading and unloading, enabling uninterrupted production.

- Key Benefits: Continuous operation, cycle time reduction, improved safety, repeatability (+/- 0.05 mm).

- Options: Roll door or light curtain for loading zones.

- Applications: Heavy and complex assemblies requiring tilt and rotation.

Featured Project: MWES developed a robotic welding solution for aerial lift weldments, increasing consistency across multiple part types.

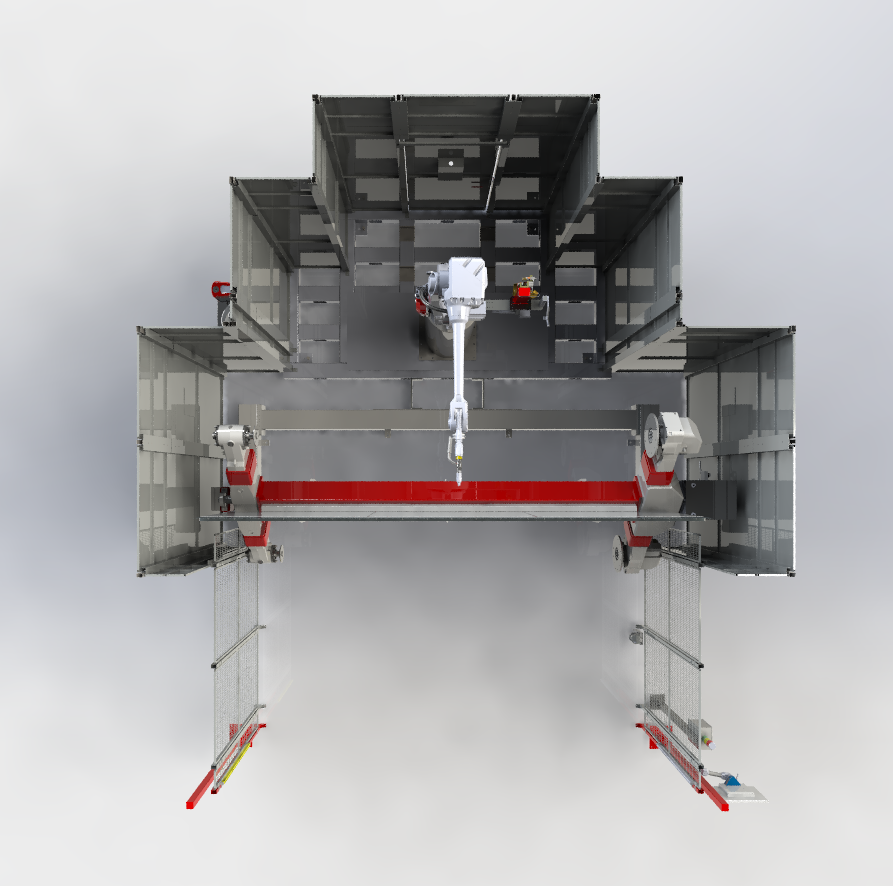

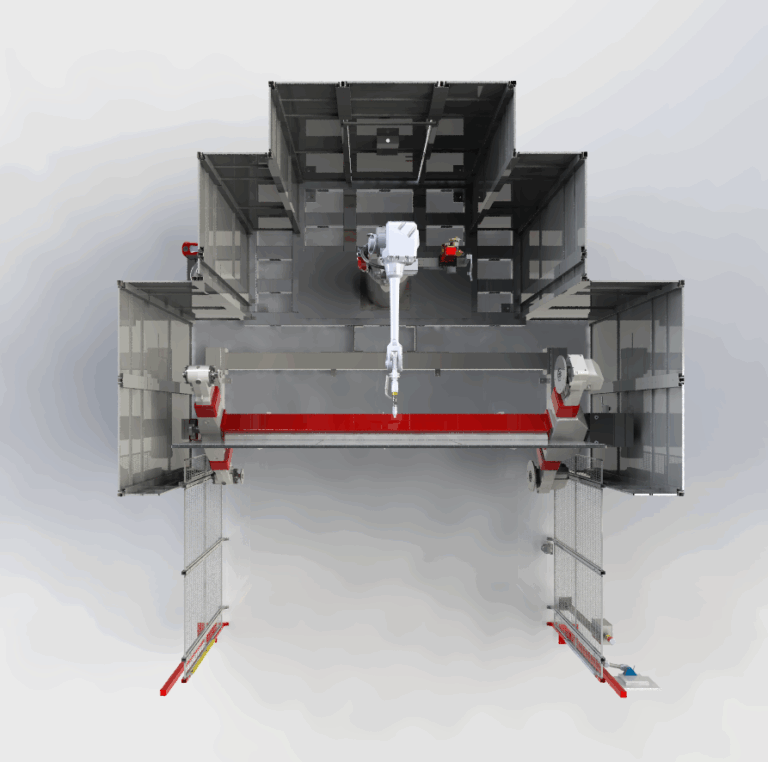

Indexing H-Frame Weld Cell

Equipped with a rotating horizontal table, this cell supports up to three robots and can handle fixtures weighing up to 1,000 kg. It enables simultaneous loading/unloading while welding is in progress.

- Key Benefits: Flexible robot capacity, quick changeovers, precision component rotation.

- Options: Roll door or light curtain loading zones.

- Applications: Medium-to-heavy assemblies requiring rotation for multi-sided welds.

Indexing Standard Weld Cell

The Standard Cell strikes a balance between performance and versatility, featuring two processing stations, rotation and tilt axes, and supporting up to three robots. Fixtures handle loads up to 1,000 kg while maintaining high repeatability.

- Key Benefits: Versatility for various part sizes, high productivity, reduced labor costs.

- Options: Three positioner variants available.

- Applications: Manufacturers requiring flexibility and fast changeovers.

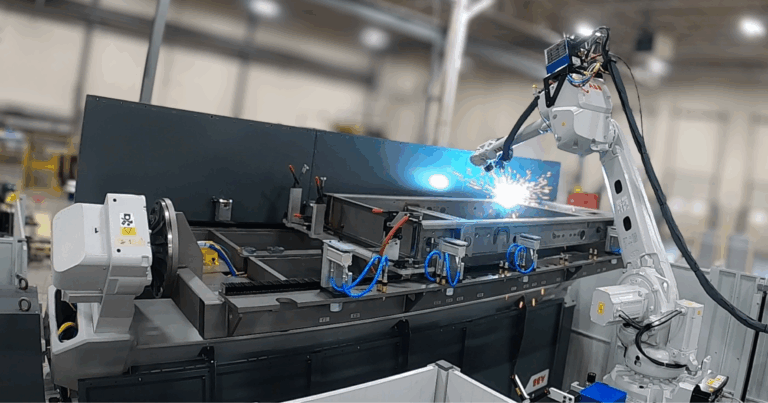

Indexing Ferris Wheel Weld Cell

The Ferris Wheel configuration uses vertical rotation for alternating stations, supporting up to two robots and loads of up to 1,000 kg. Its design is compact yet highly productive.

- Key Benefits: Space-saving vertical rotation, continuous workflow, high-speed cycle times.

- Options: Roll door or light curtain for loading zones.

- Applications: Frame welding and projects requiring compact layouts.

Featured Project: MWES designed a robotic frame welding system with custom fixturing and a 2-sided interchanging positioner.

General System Specifications Across MWES Weld Cells

- Stations: Two or more for continuous operation

- Robots: Up to three, depending on configuration

- Positioners: Rotation and tilt (2-Axis, Standard) or rotation only (H-Frame, Ferris Wheel)

- Load Capacity: 250–1,700 lbs. (varies by system)

- Repeatability: +/- 0.05 mm

- Safety Features: Roll doors, light curtains, and full enclosures

Rely on MWES for Standard Arc Weld Cells

MWES has decades of experience building turnkey welding solutions that improve throughput, safety, and weld quality. Whether you need a heavy-duty positioner cell or a space-saving Ferris Wheel system, our team can design, build, and integrate the right solution for your production requirements. Contact our Application Engineers today to learn more about our Standard Arc Weld Cells.