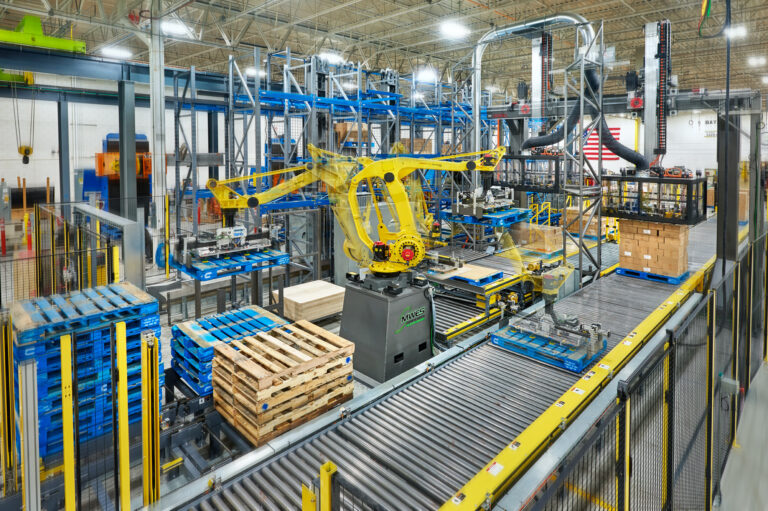

Mixed Layer Palletizing

A range of offerings provides levels of throughput from 1,000 to 3,500 layers per day increasing the fulfillment for warehouse and workers alike. Automatic scanning of inbound products ensures accurate picks from the warehouses and reduces product shrinkage. Completed loads can be stretch-wrapped and labeled automatically reducing the opportunity for missed picks and errors. Material handling can be further error-proofed with the use of mobile robotics to stage and load shipments.

Load stability is built into every order as each product and layer is validated in Midwest Engineered Systems database. Customer-based rules dictate the load and layer combinations that can be stacked. This ensures that loads arrive in the same quality condition that they are shipped in. The result is increased efficiency for the shipper and receiver alike.

MIXED LAYER Palletizing FEATURES

- Pick Single or Multiple Layers

- Secure Grasp Even with Chimneys and Voids

- WMS Interface with Workflow Simulation and Management

- Batch and Wave Enablement

- AS/RS Buffer System

- Pallet Inspection

- Mobile Robotics

- Pallet Handling

- Stretch Wrapping

- Print Label and Apply