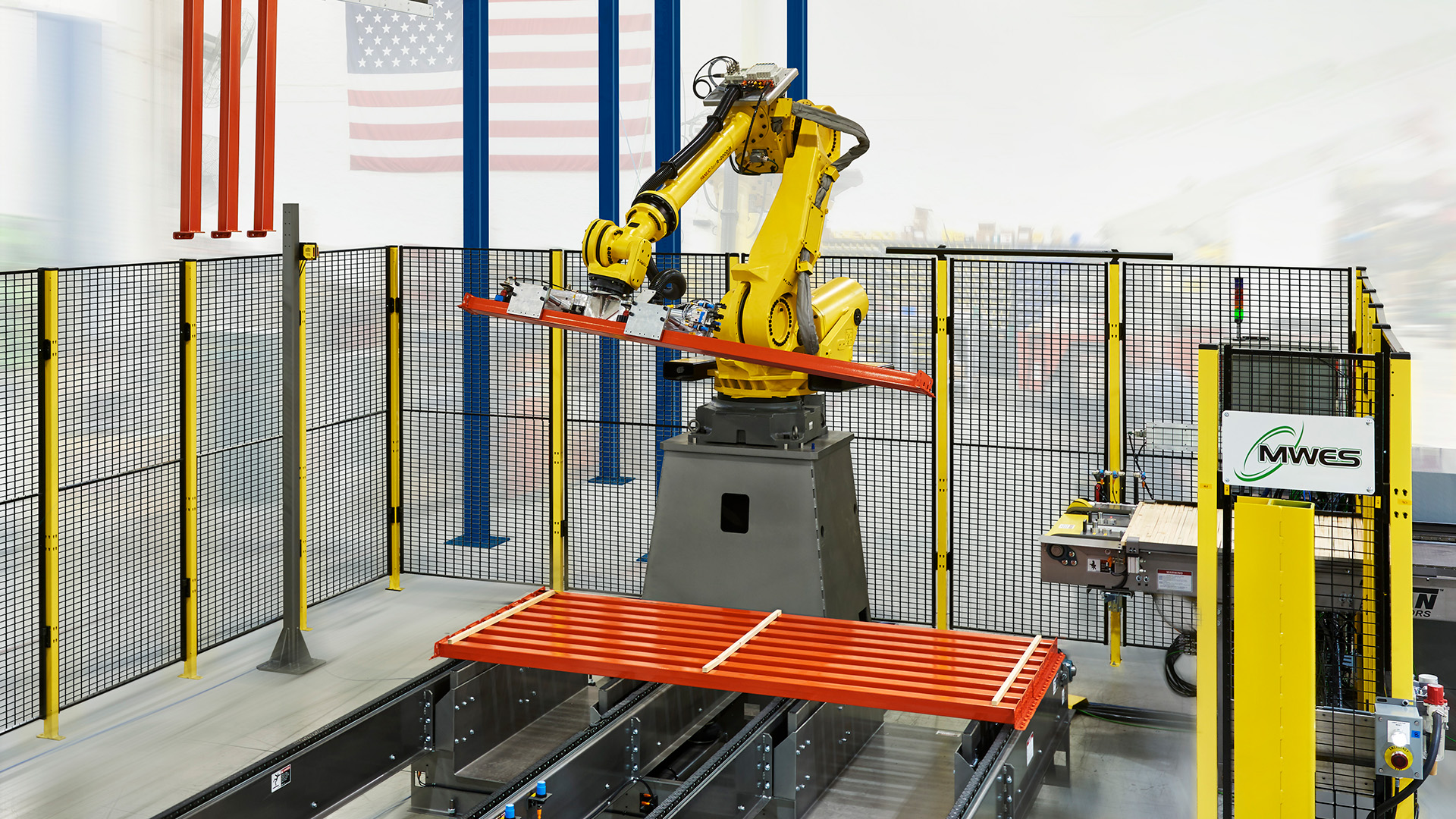

Material Handling

Automated Material Handling Solutions That Keep Your Operations Moving

From raw materials to finished goods—and every stage in between—MWES designs and integrates advanced material handling systems that keep your factory floor efficient, organized, and agile. Whether you’re moving parts between workstations, batching in-process materials, or managing inventory across facilities, our custom-engineered systems are built to align with your production flow and factory layout.

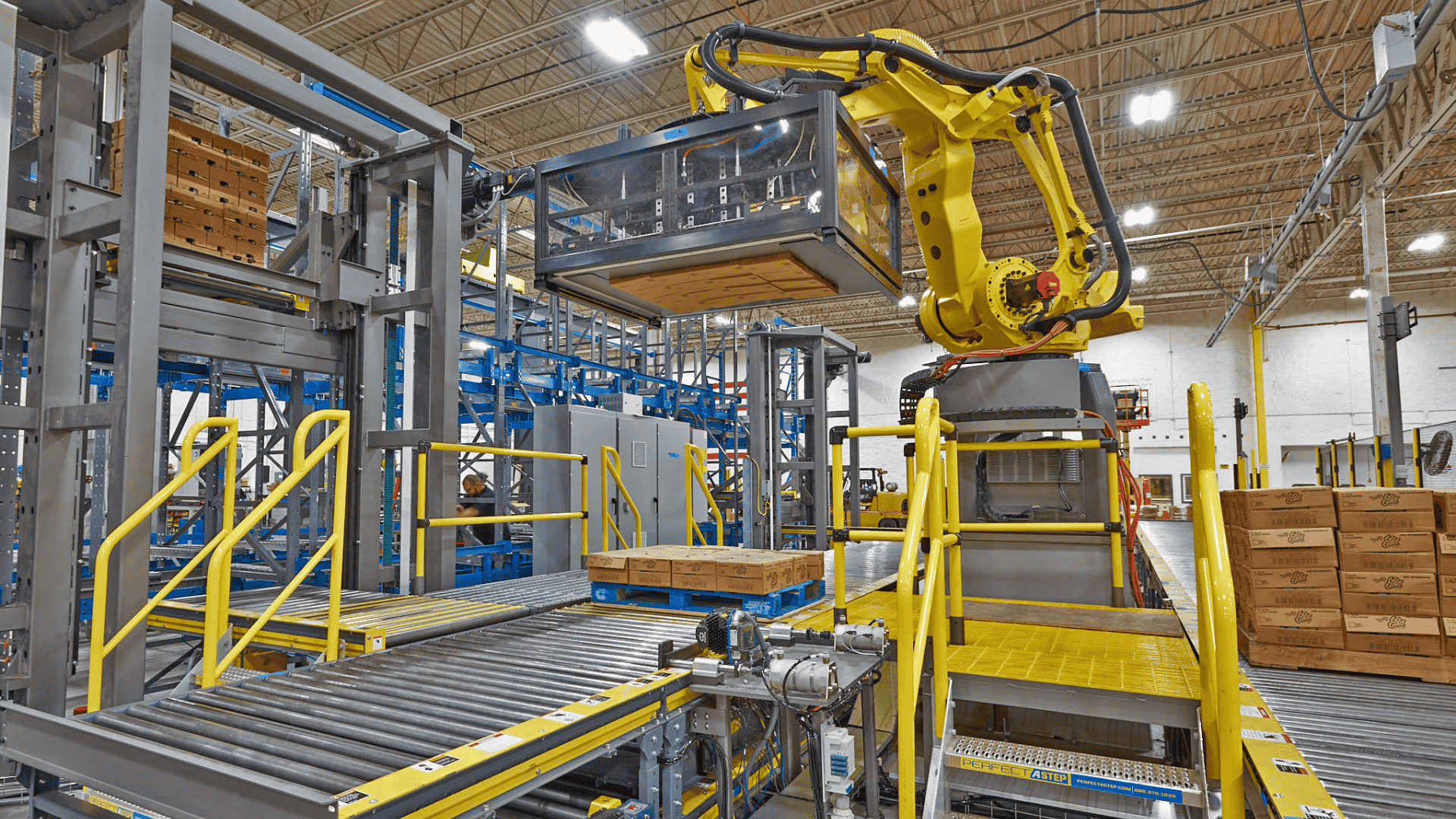

Our solutions go beyond basic transport. We incorporate Work-in-Process (WIP) management strategies, custom dunnage systems to protect part quality during transport and storage, and automated storage and retrieval systems (ASRS) that increase storage density without compromising access or inventory control. Our automated guided vehicles (AGVs) offer flexible movement of materials without the footprint or constraints of traditional conveyors—ideal for dynamic factory environments with evolving layouts.

Labor Efficiency & Safety

Labor Efficiency & Safety

Automating repetitive and heavy-lifting tasks reduces physical strain on workers while improving overall productivity and workplace safety.

Reliable Flow of Materials

Reliable Flow of Materials

Our solutions ensure precise, repeatable handling of products and materials, minimizing bottlenecks and boosting line performance.

Scalable, Smart Integration

Scalable, Smart Integration

From conveyors and lift systems to robotic transport and AGVs, our systems are scalable and designed to integrate with your current operations and future growth.