The Challenge

Manual Welding of Heavy Transformer Housings Was Inefficient & Hazardous

Large transformer housings (up to 4,000 lbs and dimensions up to 60 × 105 × 98 in) were previously welded manually using overhead cranes. This labor-intensive process lacked flexibility and posed ergonomic and quality challenges.

- Welding relied on crane handling for in-position access

- Manual programming made adapting to varied housing sizes difficult

- Weld quality was inconsistent across parts and operators

- Inefficient handling caused low throughput and high labor hours

MWES was selected for its ability to deliver automated parametric welding, real-time tooling adjustments, and seamless integration with production systems.

The Solution

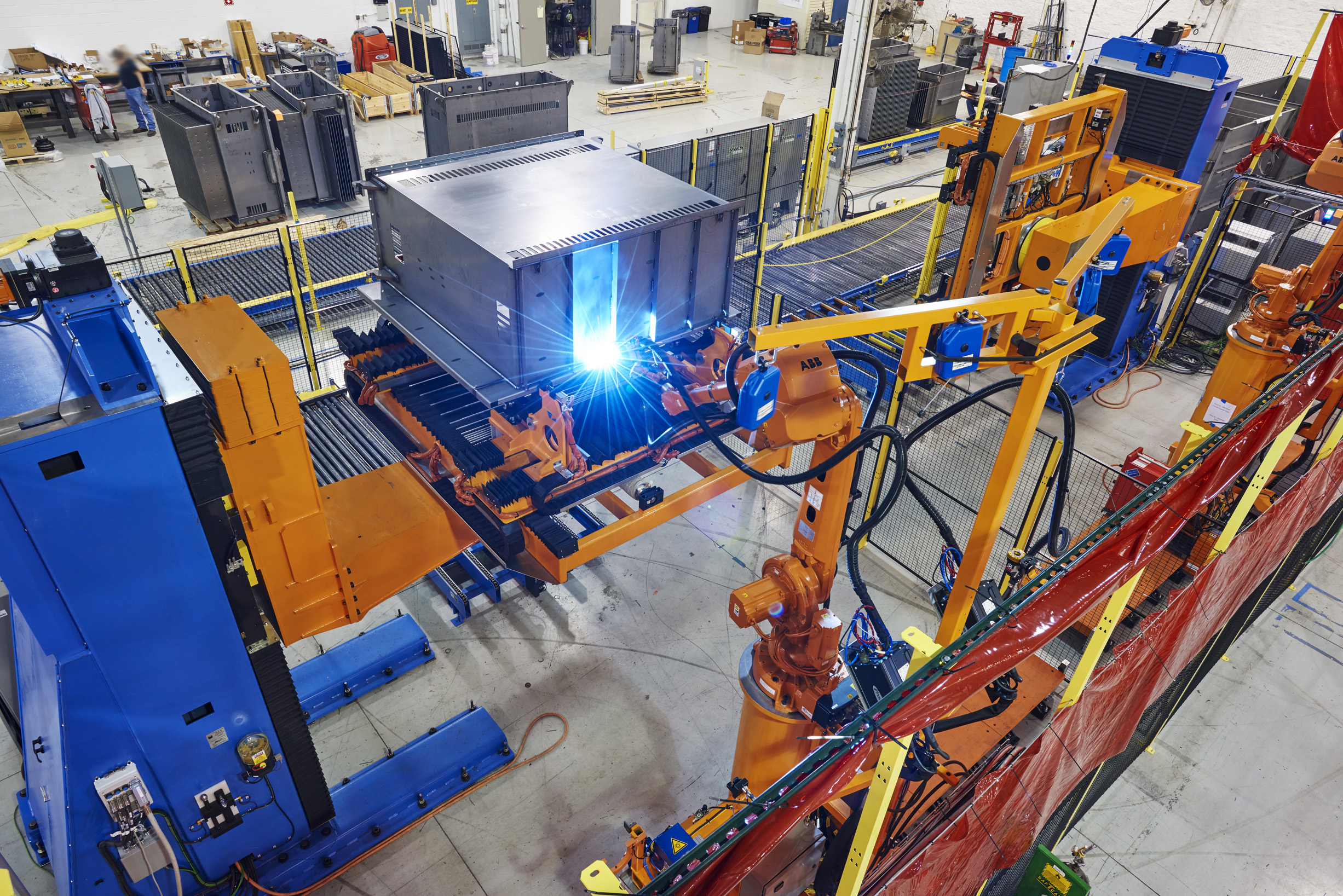

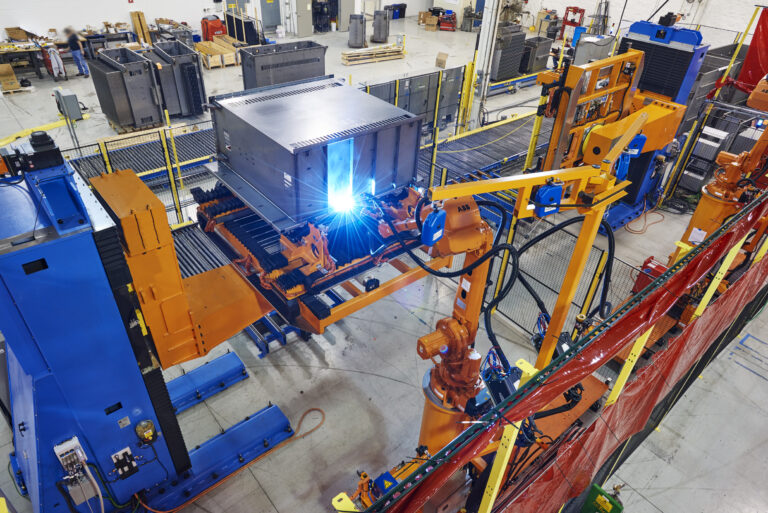

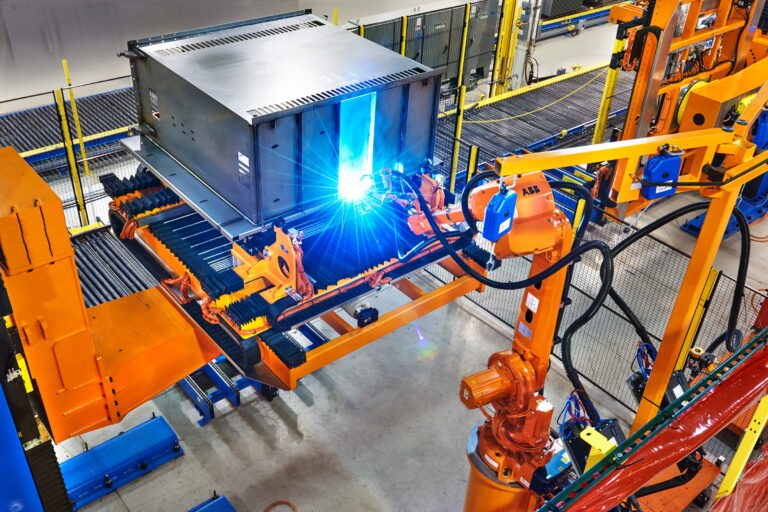

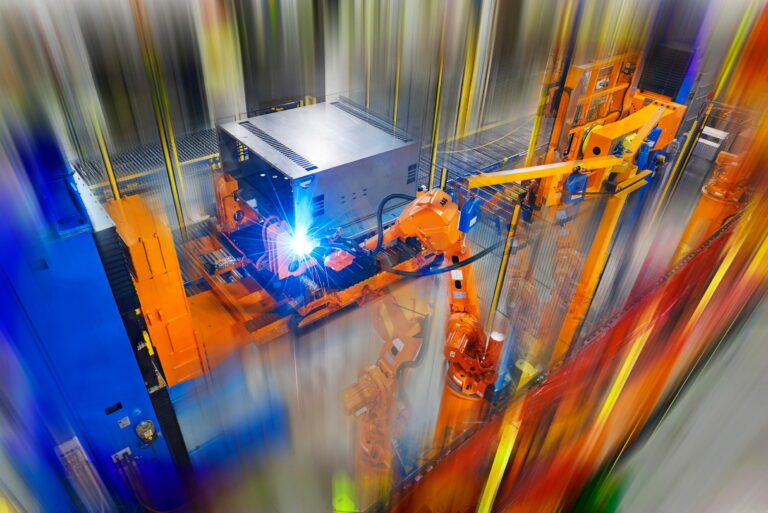

Dynamic Welding Cell with Robotic Positioning & Recipe-Based Control

MWES developed a welding cell where automated conveyors present each housing to a positioner and robot. The system communicates with the plant’s SAP/SQL database to select correct welding programs and torches based on material and size.

- Part tracking via conveyor-integrated sensors to automatically load housings onto positioner

- Use of SkyHook 3-axis servo positioners for precise part orientation up to 4,000 lbs

- ABB robots with external servo axes and automatic torch/tool switching for mild or stainless steel welds

- PLC-augmented system for parameterized program selection based on scanned part data

- Offline ABB Robot Studio programming enables new designs to be tested and validated without stopping production

All tooling, welding, and control systems adapt automatically to each unique part using barcode-referenced recipes and intelligent device logic.

The Results

Improved Quality, Throughput, and Reduced Labor Overhead

The automated welding solution delivered tangible production benefits—and eliminated unsafe crane handling while boosting quality and flexibility:

- Increased first-pass weld quality and consistency

- Reduced rework and material waste

- Higher throughput due to automated cycle times and seamless part loading

- Improved traceability via parametric program control and part-specific data integration

MWES’s robotic welding cell transformed the customer’s heavy-part fabrication process into a scalable, safer, and more efficient system.