The Challenge

Manual Pallet Building Slowed by Variety and Volume

Manual pallet stacking of diverse product formats—cases, trays, and varied heights—was inefficient and prone to inconsistencies. The customer needed automation that would:

- Handle both tray and case formats on the same line

- Build pallets to varying heights and patterns as required

- Integrate seamlessly with existing conveyor infrastructure

- Scale throughput while reducing labor dependency

MWES was selected to create a single automated solution flexible enough to accommodate multiple pack types and pallet configurations.

The Solution

Two-Robot Hybrid Palletizer with Patterning and Tray-Layer Control

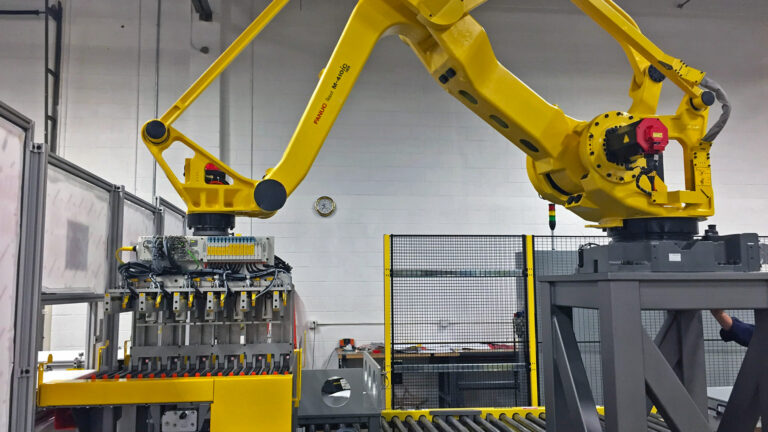

MWES engineered a robotic palletizer featuring:

- Two high-capacity FANUC robots—one for tray handling and one for cases

- Intelligent layer patterning logic and sequence control via PLC

- Automated layer sheet application and pallet height sensors

- Compact footprint with easy integration into existing facility layout

The system dynamically switches between tray and case stacking routines and builds pallet layers to customer-specified configurations—enabling fast changeovers and flexible operations. It automatically sequences product stacks and pallet sheet insertion without operator intervention.

The Results

Improved Throughput, Accuracy, and Reduced Labor

This palletizing solution delivered tangible operational benefits:

- Fully automated handling of mixed tray and case formats

- Increased stacking accuracy and reduced layer misalignment

- Labor saved through continuous robotic operation across multi-shift production

- Scalable throughput without adding workforce resources

By combining tray and case palletizing into one unified robotics cell, MWES helped the customer achieve faster, safer, and more reliable load staging.