The Challenge

Manual Layer Picking Strained Labor, Accuracy & Safety

Facing severe labor shortages, inconsistent throughput, and worker safety concerns in a refrigerated fulfillment environment, the customer needed an efficient, reliable way to automate pallet-to-order staging.

- Staffing shortages disrupted order fulfillment

- Manual case separation proved slow and error-prone

- Workers struggled with bulk layers weighing up to 500 lbs

- Throughput and accuracy were inconsistent and difficult to scale

The customer required a layer-picking automation capable of high throughput, precise order build sequencing (based on WMS logic), and minimal operator labor.

The Solution

Vision-Guided Robot Layer Picker with WMS Integration & Pallet Build Optimization

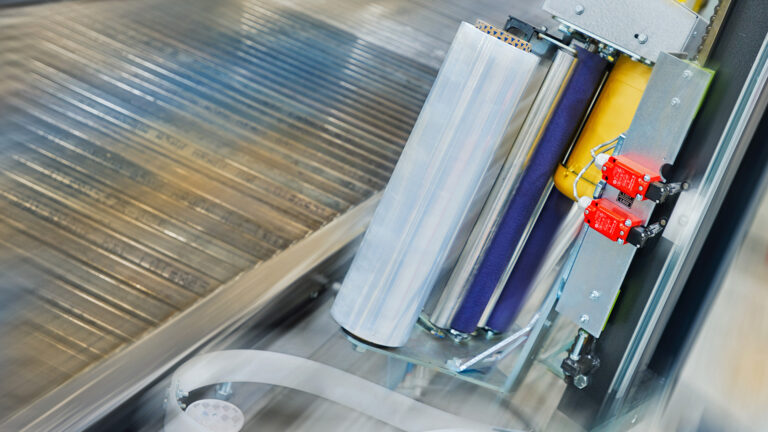

MWES engineered an advanced robotic layer-picking system that interfaces with the customer’s WMS to sequence layer picks and orchestrate order pallet buildouts. The software optimizes pallet building and coordinates with an automated conveyor, vision camera system, and stretch wrapper station.

- FANUC M‑410iB/700 robot equipped with custom vacuum EOAT

- Multi-axis vision system separates layer‑quantity orders from non‑layer picks

- Custom software optimizes build sequences and maximizes pallet fill

- Integrated WMS interface guides operator on feed sequence, order pallet wrapping, and staging

The system automates layer-to-order operations end‑to‑end—reducing operator touchpoints and streamlining logistics within existing infrastructure.

The Results

30‑Second Cycle Time, Robust Throughput & Minimal Labor Oversight

MWES’s solution enabled consistent, high-volume order fulfillment with reduced staffing and improved safety.

- Achieved a 30 second layer pick cycle time (~120 picks/hour)

- Supported heavy layer weights (~500 lbs) with safe robotic operation

- Required only a single operator for oversight

- Enabled 24/7 operation with consistent throughput in refrigerated environment

This robotic automation dramatically reduced manual labor dependency while increasing order accuracy and fulfillment speed.