The Challenge

Streamlining Manual Cutting & Punching of Diverse Sheet Metal Parts

Manual loading and processing of large sheet menaced throughput and introduced inconsistency. The customer needed automation to:

- Efficiently cut and punch multiple sheet metal parts per shift

- Support mixed batch sizes and varying part configurations

- Ensure precise hole placement and edge finishes with minimal recall

- Improve operator ergonomics and eliminate manual repetitive tasks

MWES was selected for its expertise in integrating laser cutting, punch tooling, and robotic part handling in sheet-metal production.

The Solution

Cell Integrating CNC Cutting, Robotic Tool Changes & Automated Stacking

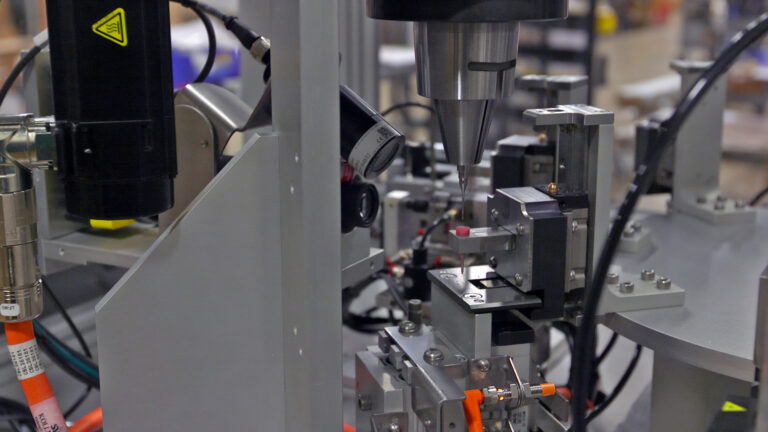

MWES delivered a fully automated cut-punch workstation that includes:

- Laser cutting and turret punch integration with tool-change automation

- CNC controller for dynamic part sampling, hole patterns, and edge considerations

- Robotic arm for retrieval, part marking (barcode or inkjet), and stacking

- Staging conveyors for offloading finished parts automatically

- Safety-rated enclosures, part detection, and operator HMI for job changeovers

This system enables lights-out cutting, punching, marking, and stacking of sheet-metal parts while an operator simply manages job setup and material supply.

Summary sentence: The automated cut-and-punch line combines CNC machining, robotic handling, marking, and stacking—delivering high speed and flexibility without manual fatigue or error.

The Results

Enhanced Throughput, Precision, and Labor Efficiency

After commissioning, the automation delivered clear benefits:

- Increased part output with repeatable precision across varied configurations

- Eliminated fatigue and misalignment associated with manual punching

- Enabled fast job changeover and reduced scrap from tool or machine error

- Required fewer operators while maintaining high volume throughput

By combining advanced CNC tooling with robotic handling and integrated marking, MWES helped the customer modernize legacy sheet-metal operations—enhancing throughput, accuracy, and operator safety.