The Challenge

Safe, Consistent Coating of Heavy, Variable Stock Parts

Handling dense alloy billets weighing between 40–1,500 lbs through multiple preparation steps was slow, inconsistent, and ergonomically risky. The customer needed automation to:

- Apply uniform Boron Nitride coating to heavy stock pre-forging

- Process all external surfaces—including reorienting the part mid-cycle

- Integrate grit blasting, heating, coating, and marking into a continuous flow

- Eliminate manual handling risks and ensure repeatability

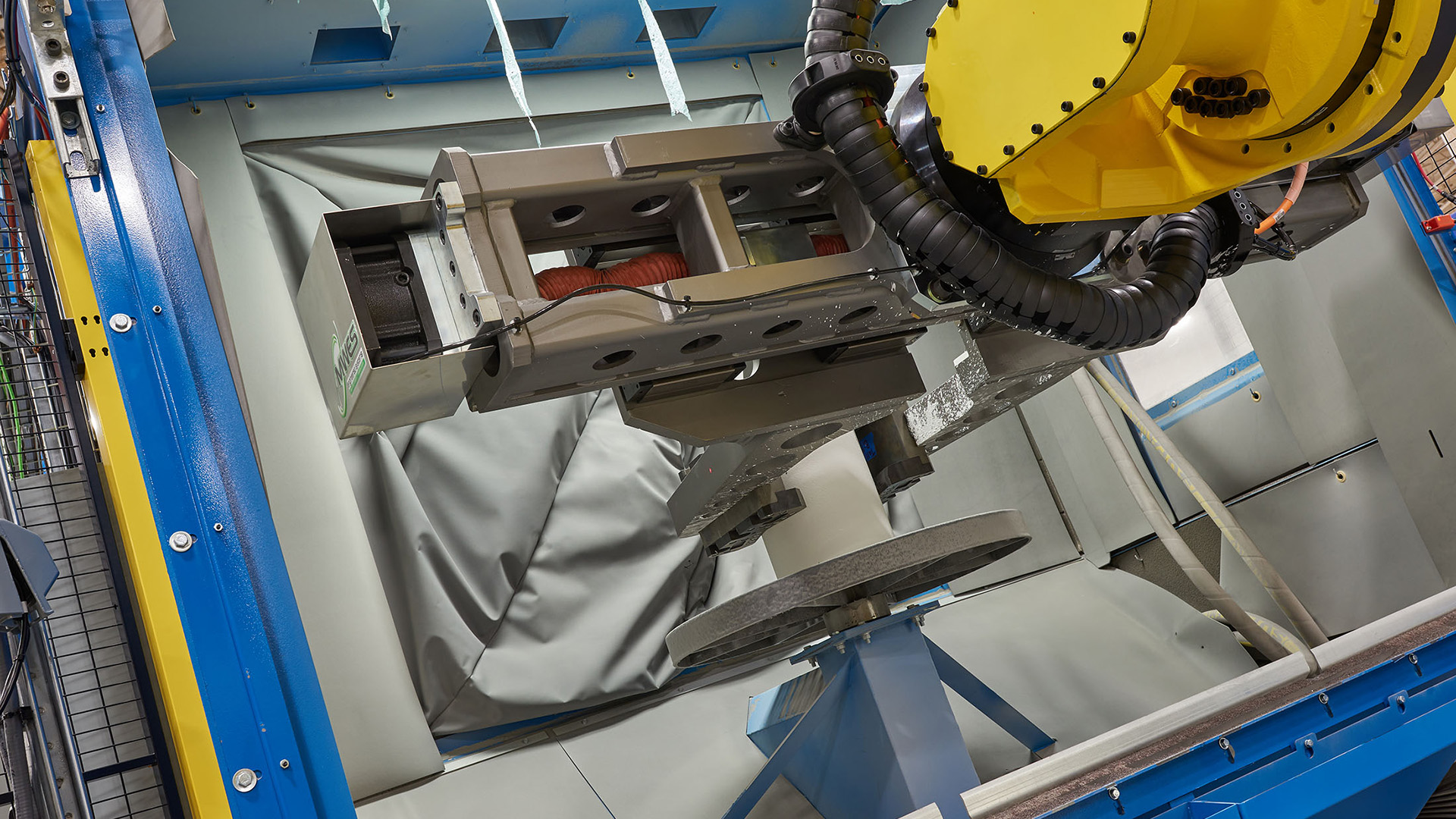

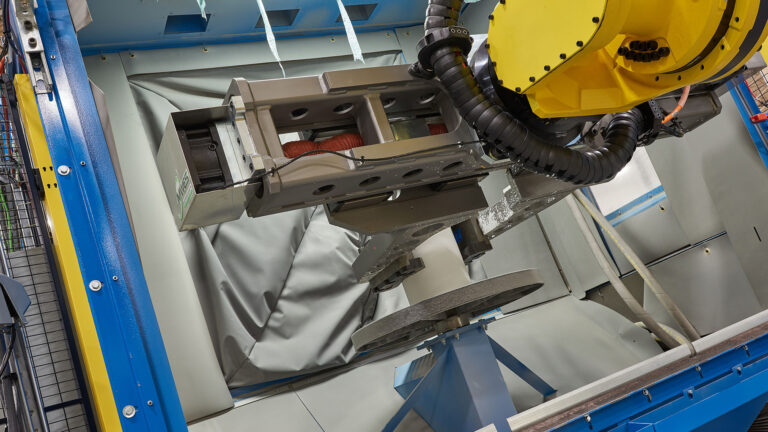

MWES was selected to design a robust robotic cell capable of full preparation workflow for heavy billets prior to forging.

The Solution

Fully Robotic Cell Featuring Blasting, Oven Heating, Coating, Flip & Marking

MWES designed and deployed an automated coating work cell that includes:

- Conveyor-fed pallet infeed loaded via forklift, with vision-guided billet detection

- Robot pick-and-place to weighing scale and laser height sensor for part identification

- Dual robotic operations: grit blasting and part flipping as required

- Oven station to heat billet to target temperature, followed by turntable spraying of Boron Nitride coating (sides/top)

- Robot flips the billet to coat remaining surfaces

- Final barcode marking and placement back on pallet or reject stream if inspection fails

This turnkey system automates the entire stock-coat workflow—blasting, heating, coating, inspection, flipping, marking, and sorting—while handling variable billet sizes and minimizing operator touch.

Summary: The cell combines precision handling, thermal treatment, and coating in a single robotic flow—enabling consistent part preparation before forging without manual intervention.

The Results

Improved Throughput, Safety, and Coating Consistency

Implementation of the automated cell delivered tangible benefits:

- Safe handling of 40–1,500 lb alloy billets without manual labor

- Uniform Boron Nitride coating with full-surface coverage via robotic rotation

- Efficient grit blasting and temperature control for improved coating adhesion

- Integrated inspection, barcode marking, and automated reject logic

By automating this complex pre-forging preparation process, MWES enabled repeatable, high-quality stock coating while reducing handling risk and labor requirements.