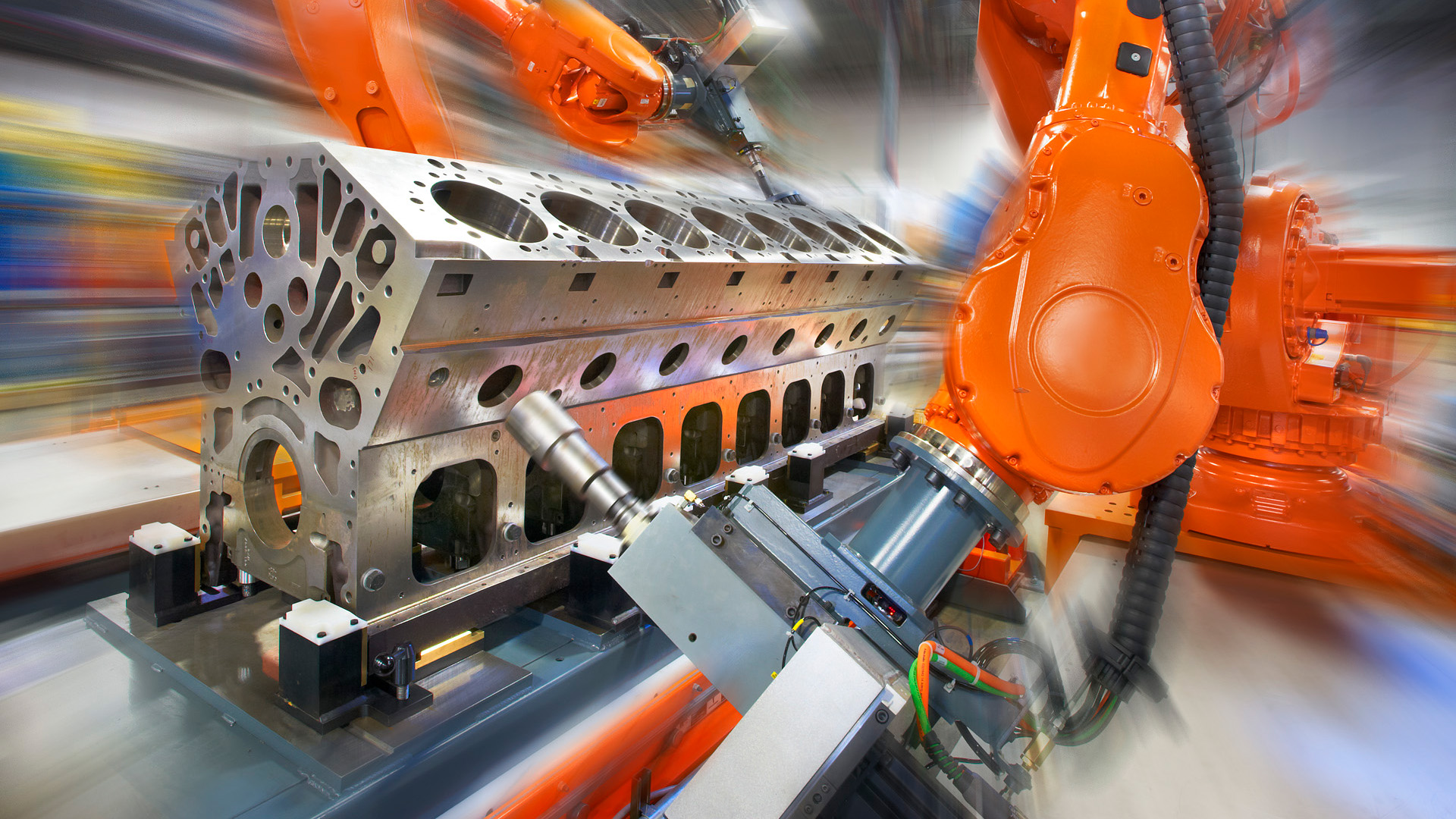

Material Removal

Precision Material Removal Automation for High-Quality Results

At MWES, we design and integrate robotic material removal systems that deliver the speed, accuracy, and consistency required for cutting, trimming, grinding, or deburring even the most complex components. Every system is custom-engineered to suit your unique part geometry, material type, and production targets—helping you reduce cycle times while enhancing finish quality and operator safety.

Our engineering expertise in metallurgy, geometric dimensioning and tolerancing (GD&T), and in-process quality assurance ensures that each solution is built for robust, repeatable performance. We collaborate closely with your team to define critical quality checkpoints—both before and after material removal—enabling tighter control over the entire manufacturing process. Whether working with lightweight plastics or high-strength alloys, MWES systems are designed for precise material interaction and surface finish integrity from first part to last.

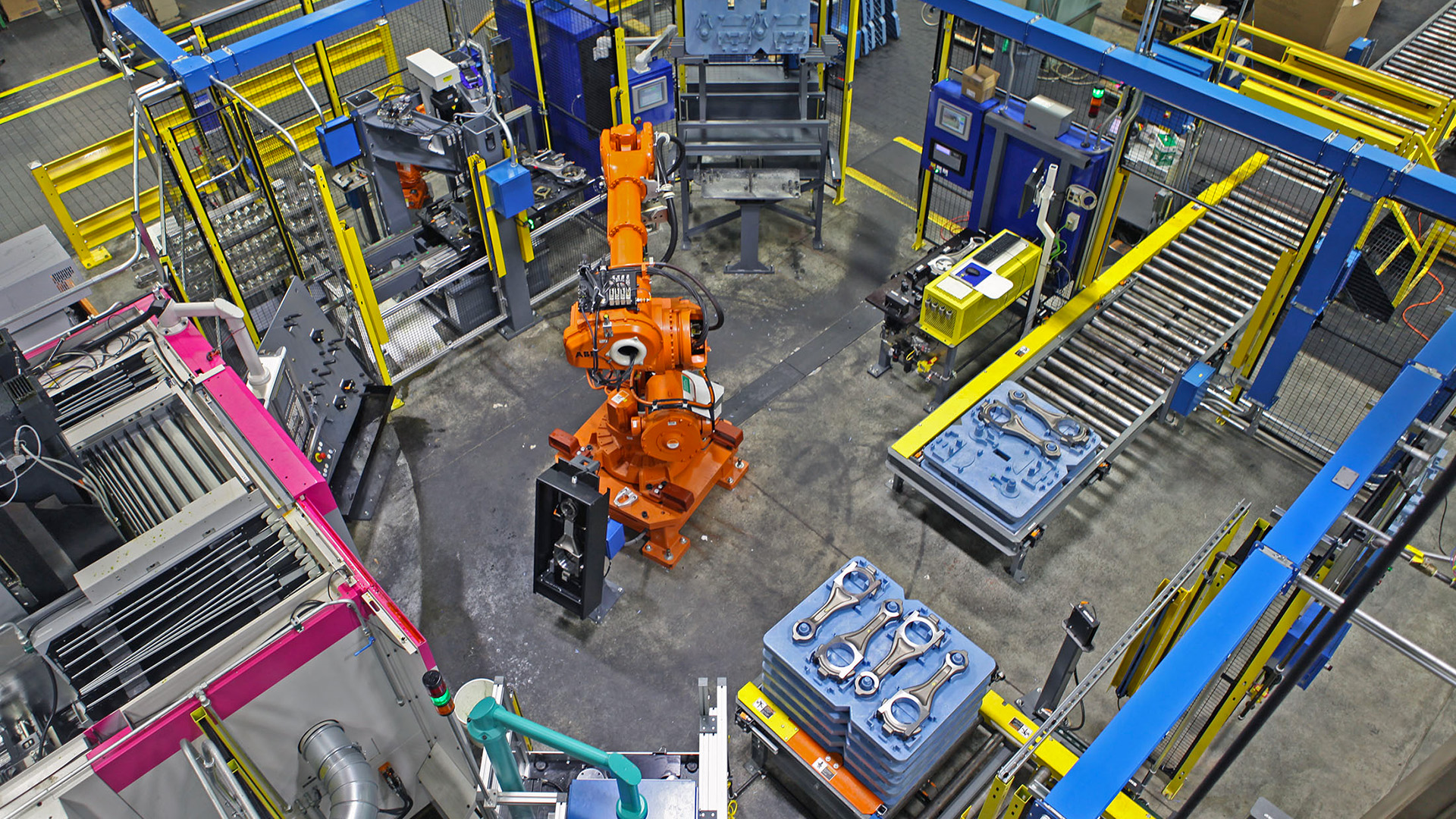

Repeatable, High-Precision Results

Repeatable, High-Precision Results

Robotic material removal ensures consistent finish quality—cut after cut, part after part—with minimal operator intervention and reduced rework.

Safer, Cleaner Work Environments

Safer, Cleaner Work Environments

Automating hazardous and high-dust processes reduces exposure to airborne particles, repetitive motion, and harmful noise—improving safety and workplace conditions.