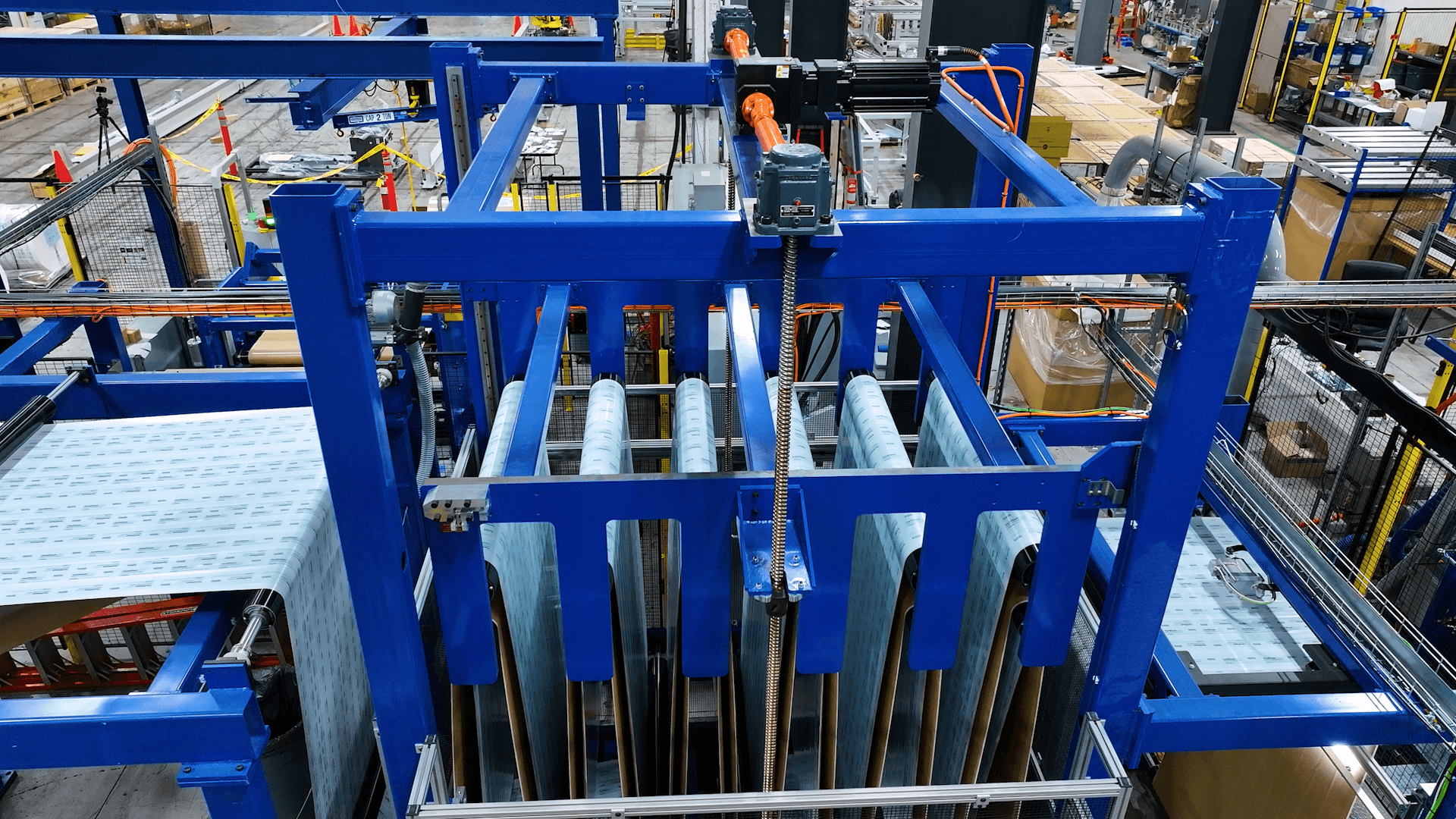

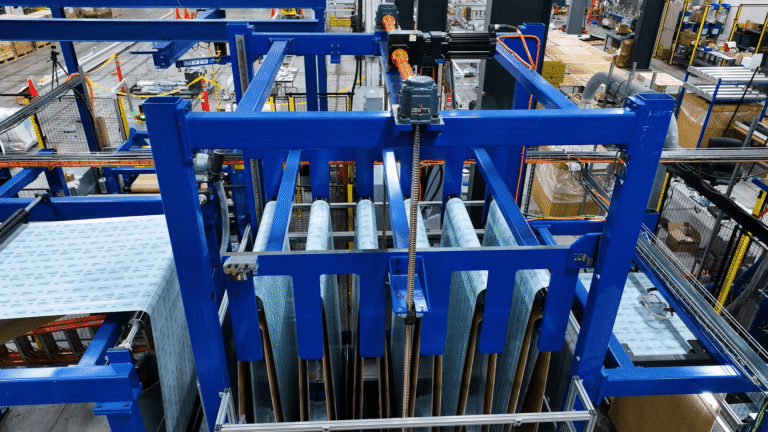

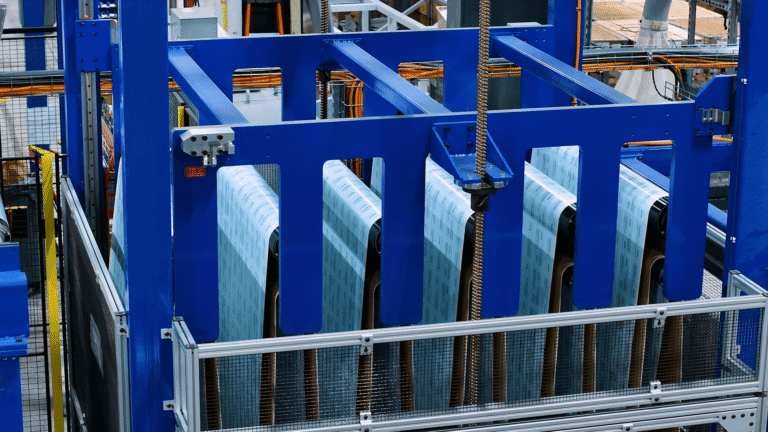

Accumulators

How Accumulators Improve Web Handling Performance

Accumulators serve as critical buffers between continuous and intermittent processes, allowing one section of the line to stop or slow down without disrupting overall web movement. By storing material under controlled tension, they maintain steady web flow during roll splicing, winder changeovers, or indexing operations—ensuring maximum uptime and consistent product quality.

MWES Accumulator Designs and Capabilities

MWES offers custom accumulator designs for a wide range of web types and materials. Our systems are built for precision and flexibility with:

- Vertical or Horizontal Configurations for low- or high-tension processes

- Servo-Driven or Motor-Driven Carriage Control for smooth, accurate web management

- Custom Capacity & Span Design optimized for material type and line speed

- Low-Inertia Rollers and Precision Bearings to reduce tension variation and wrinkling

- Integrated Tension Control Systems for synchronized operation with unwind and rewind units

Designed for Stability, Safety & Quality

Proper accumulator design and alignment are essential to avoid web defects such as wrinkles, tension spikes, or misalignment. MWES engineers every system to maintain uniform span tension, minimize friction, and ensure reliable motion through every production cycle. From aluminum and carbon-fiber rollers to low-friction carriage systems, each detail contributes to stable, repeatable web handling performance.

Whether you’re integrating an accumulator into a new converting line or upgrading an existing process, MWES delivers the precision engineering and proven expertise to keep your operation running smoothly and efficiently.