The Challenge

Manual Assembly of Triggers Was Slow, Inconsistent, and Labor-Intensive

The customer faced significant bottlenecks due to manual bottle-trigger assembly, including:

- Sorting and orienting various trigger types on a conveyor

- Attaching triggers to bottles with precise torque and alignment

- Ensuring ultrasonic weld integrity for leak-proof assembly

- Maintaining cycle time while enforcing compliant quality standards

MWES was selected to design and deliver a complete automation cell capable of reliably executing multi-step assembly with built-in inspection and minimal human oversight.

The Solution

Vision-Guided Robotic Assembly Line with Torque Control & Ultrasonic Welding

MWES provided a compact, automated assembly cell featuring:

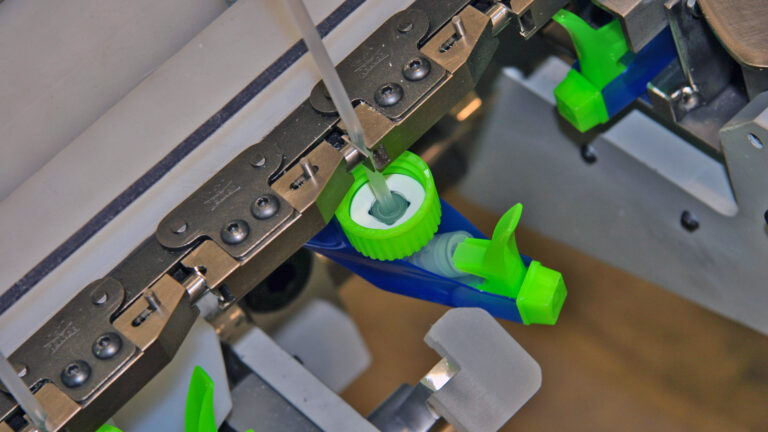

- Vision-guided pick-and-place robots to orient triggers and place them on bottles

- Pneumatic-driven torque fixtures to ensure proper trigger closure

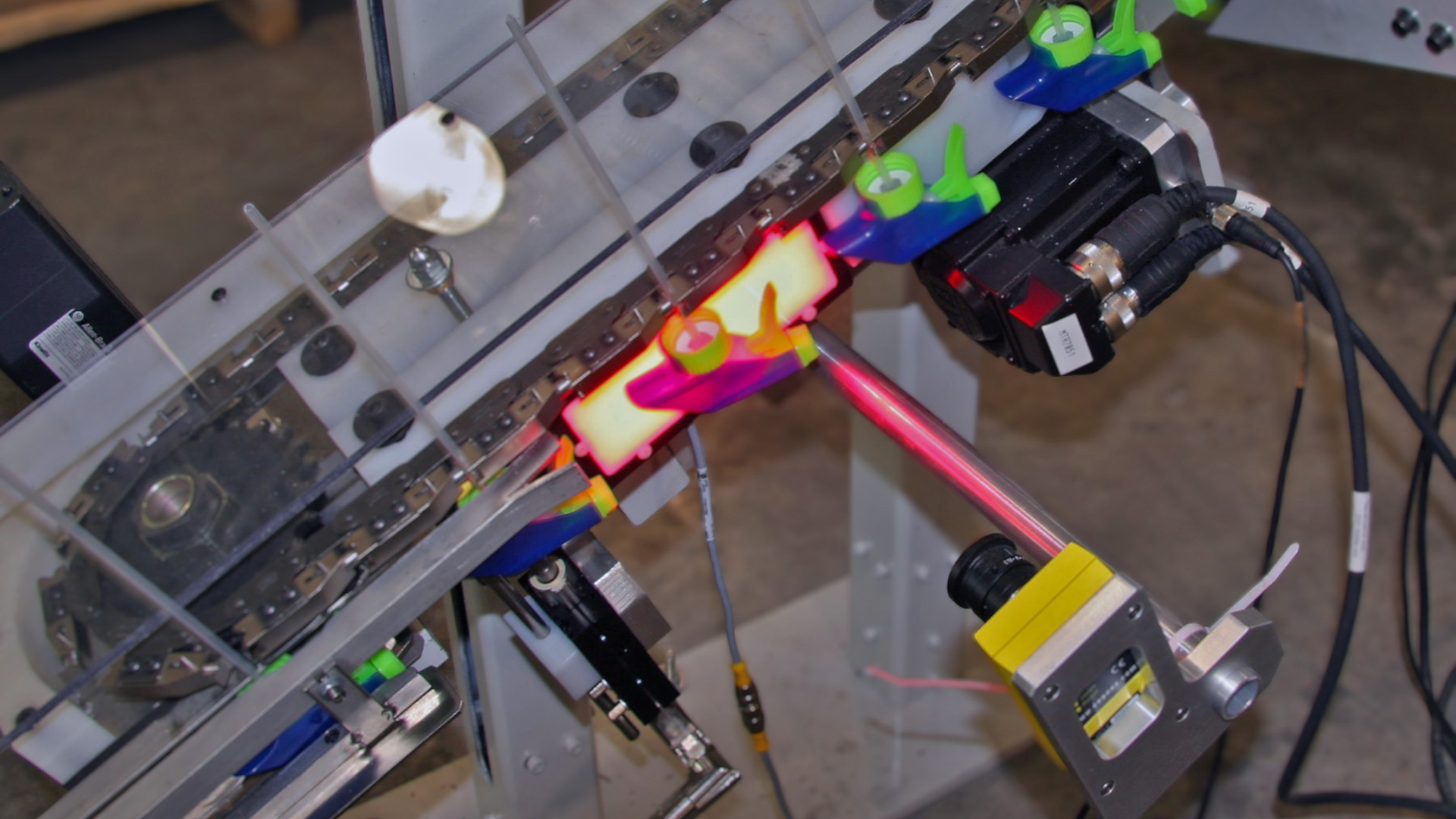

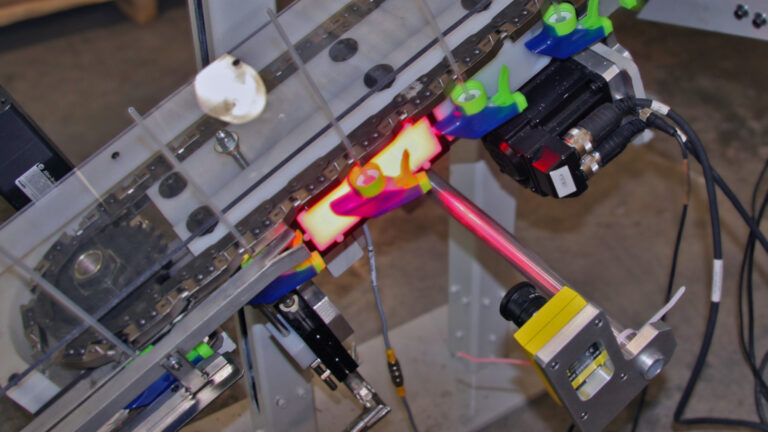

- Ultrasonic welding station to seal trigger attachment reliably

- Integrated part presence verification and torque validation via sensors

The system coordinates multiple robots and modules in sequence—trigger pick, torque cycle, ultrasonic weld, and final validation—enabling high-speed production in one unified automated line.

In summary, this robotic cell seamlessly integrates vision, torque control, and welding to automate critical trigger assembly steps with consistent quality and minimal human touch.

The Results

5-Second Assembly Cycle, Full Verification, and Labor-Free Operation

The MWES assembly solution enabled measurable improvements:

- Delivered a full trigger assembly in 5 seconds or less per unit

- Ensured 100% part validation and torque/weld quality tracking

- Reduced dependence on manual labor and eliminated operator variances

- Enabled more efficient production scaling with higher uptime

By deploying a high-speed, vision-guided robotic solution, MWES helped the customer achieve reliable assembly throughput, consistent product quality, and reduced labor costs—all in a compact system footprint.