The Challenge

Manual Spring Assembly Lacked Speed and Consistency

Spring insertion onto soft rubber seals is delicate and repetitive—often inconsistent and inefficient when performed manually. The manufacturer needed a system to:

- Insert small springs precisely onto rubber seals

- Support two-part feeding systems (input seals and springs)

- Automatically inspect and reject improper assemblies

- Deliver high throughput with consistent part quality

MWES was selected to design a turnkey, feed-to-sort solution that could handle small parts reliably and adapt to product variation.

The Solution

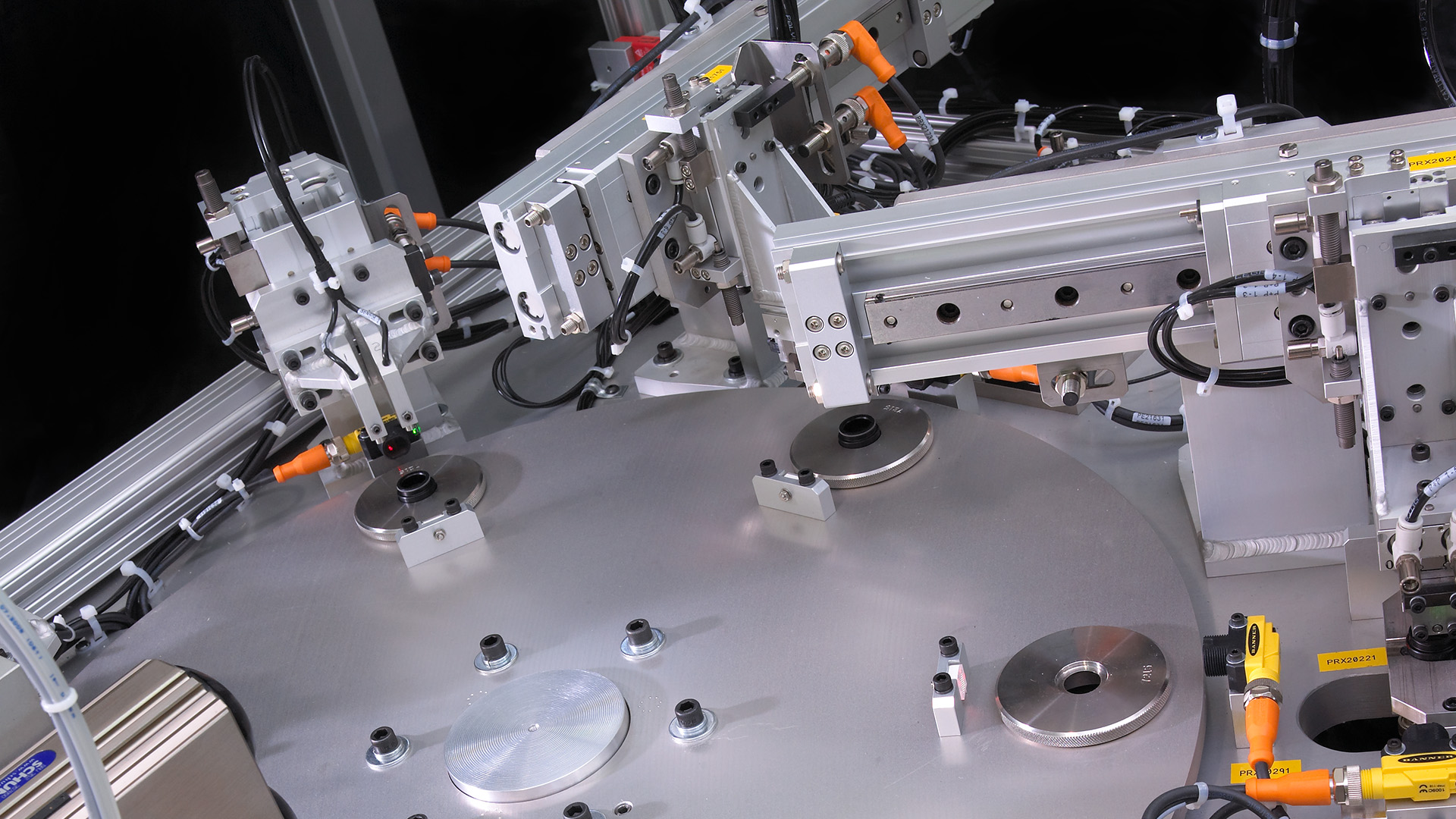

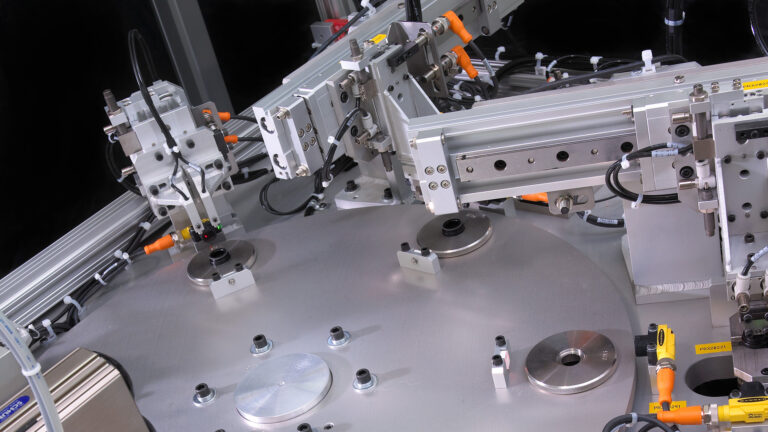

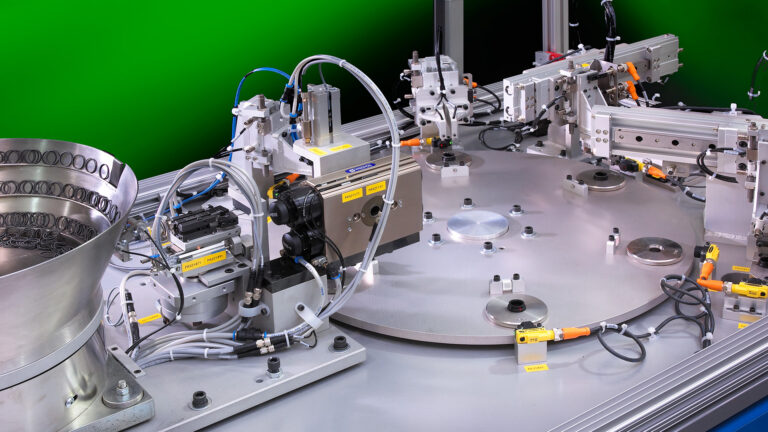

Vibratory Feeders with Dial Indexer and Integrated Quality Inspection

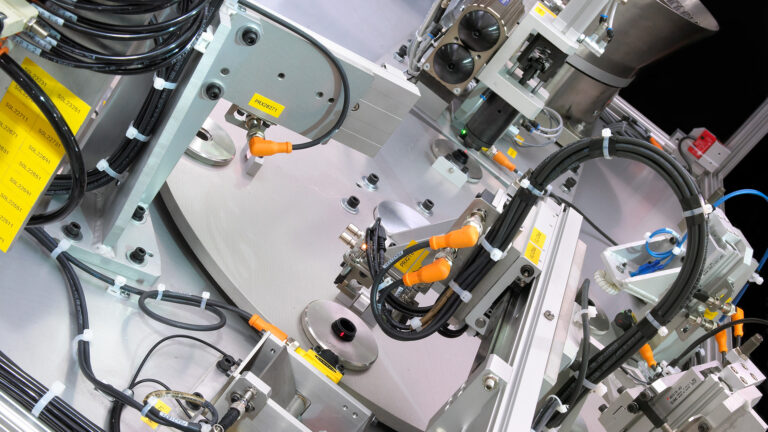

MWES engineered a complete assembly cell featuring:

- A 15-inch vibratory bowl feeder for rubber input seals

- A second bowl feeder for springs, feeding into a six-station Camco dial indexer

- Quick-change fixture tooling to support multiple parts and models

- Conductivity and proximity sensors for spring installation verification

- Pneumatic pick-and-place pick-off at unload station with pass/fail binning

The sealed assembly rotates through stations for load, verify, assemble, inspect, and unload—all with minimal operator involvement.

The Results

Consistent Quality, High Throughput, and Reliable Assembly

The automated spring assembly system delivered measurable gains:

- Achieved production rates of 1,200 assemblies per hour

- Ensured 100% inspection of spring presence and seating

- Eliminated operator variability in a precise, repetitive task

- Validated quality inline with verification sensors

By combining precision feeding, automated assembly, and real-time inspection, MWES provided a dependable solution for high-volume, high-quality spring assembly.