The Challenge

Efficient and Accurate Welding of Heavy, Multi-Part Pipe Assemblies

Fabricating 3-piece pipe weldments—often over 1,000 lb—posed several key challenges:

- Automating weld joins across curved seams and compound joints

- Handling large, heavy parts without crane dependence

- Maintaining consistent & repeatable weld quality via precise positioning

- Reducing manual labor and rework in large-part welding

MWES was selected for its proven experience building robotic welding cells for complex, high-mix pipe structures and integration of multi-axis positioners.

The Solution

Dual-Station Robotic Cell Featuring Servo Positioners & Automated Torch Maintenance

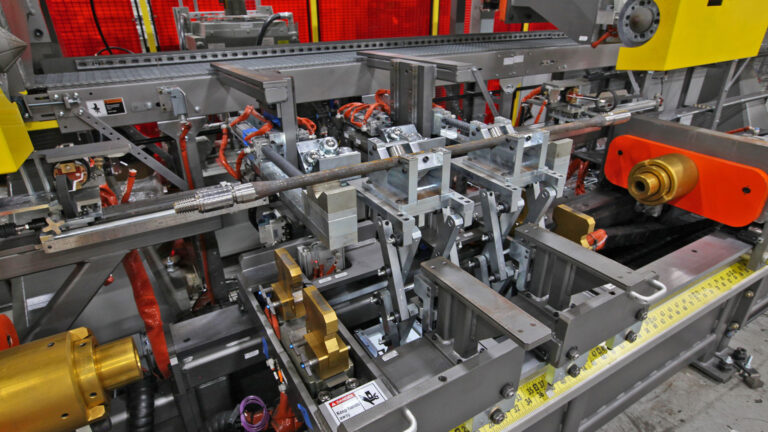

MWES built a turnkey system including:

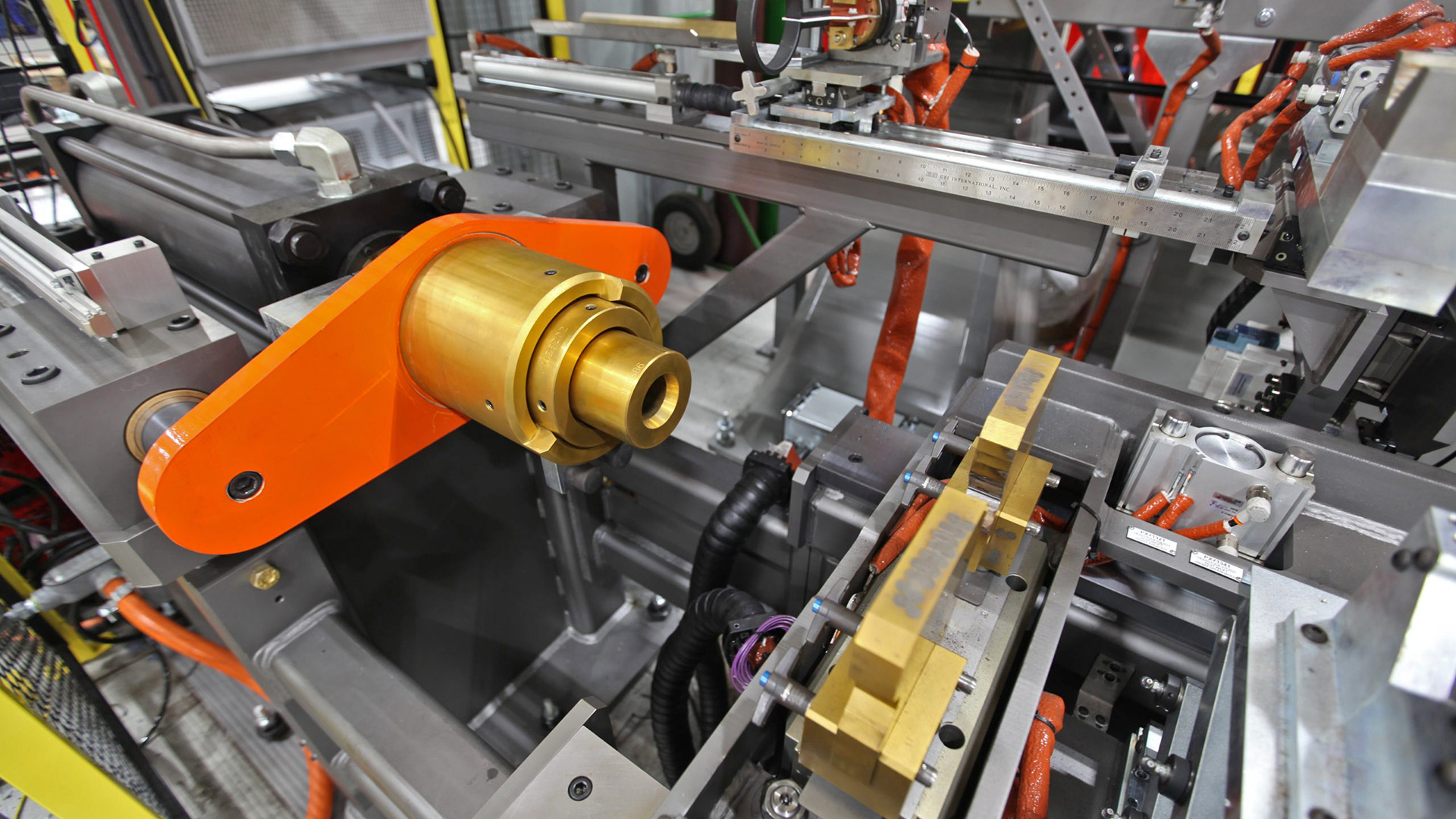

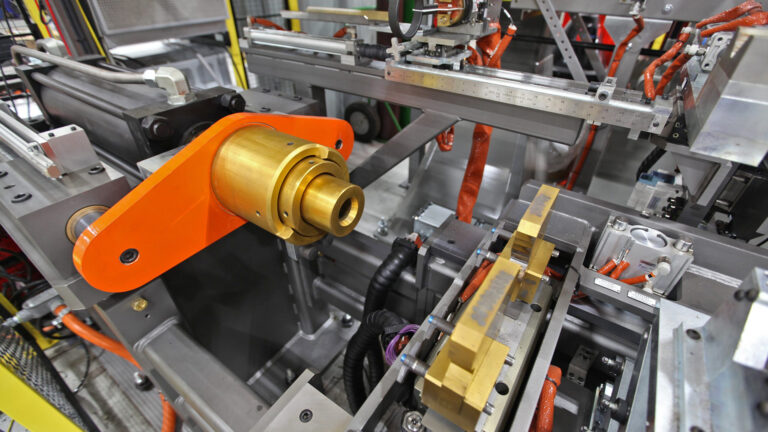

- Floor-mounted SkyHook 4-axis servo positioner to support pipes up to 14 ft in length

- Two welding zones: one for root welding and one for cap welding

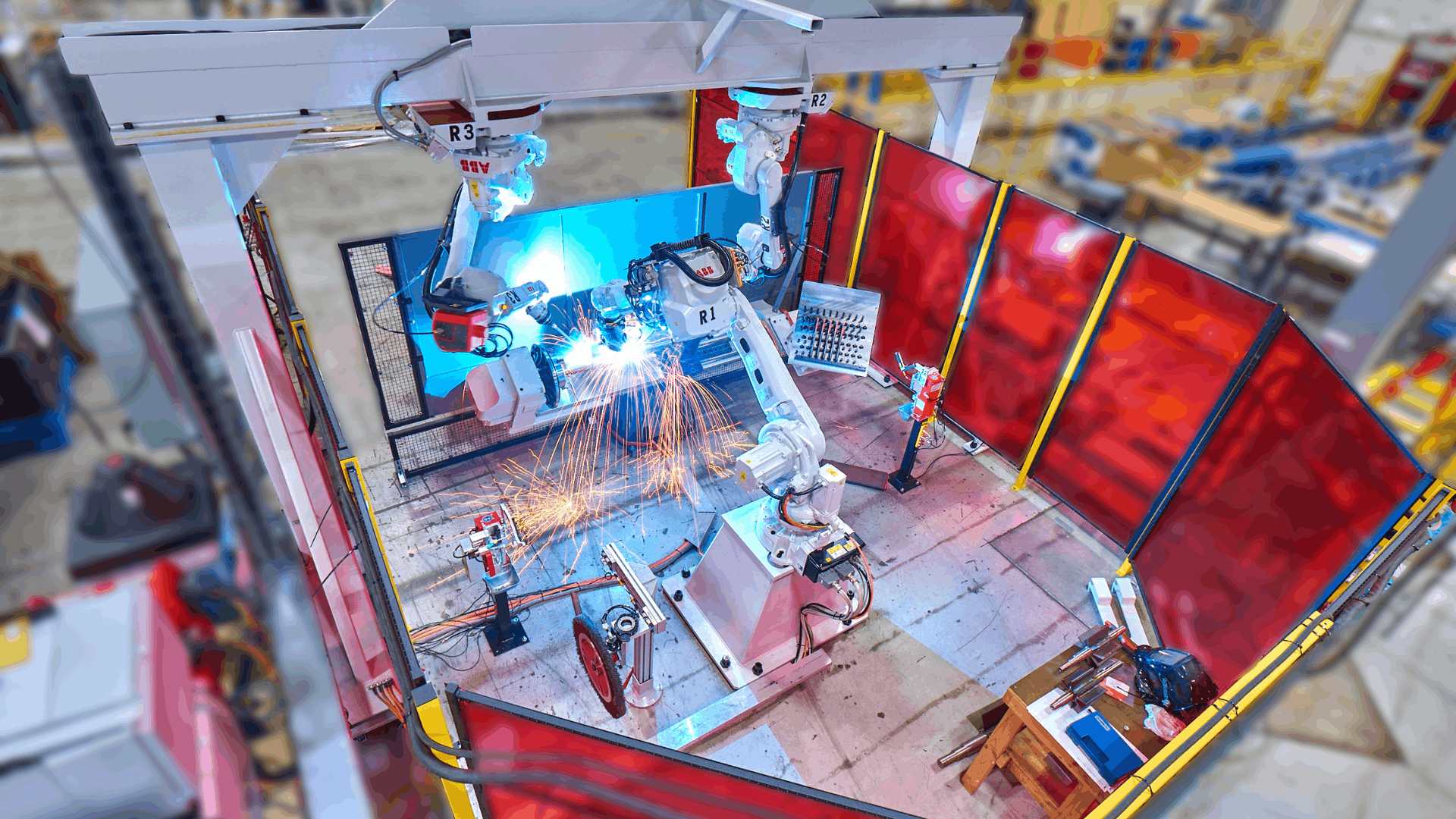

- Hot-pass and cap-pass welding sequences performed via dual ABB welding robots

- Automated torch maintenance station to clean and dress tips on demand

- Recipe-based control for part size and material tracking, with load/unload station mirrored on opposite side

- Safety interlocked light curtains and integrated cell flow logic

This solution integrates robot welding, torch maintenance, and part positioning seamlessly. In summary, the system delivers a continuous, precision-supported weld workflow—achieving consistent quality without operator intervention.

The Results

Faster Cycle Times, Consistent Weld Quality & Safer Operations

The MWES pipe weld cell delivered impactful results:

- Achieved consistent, repeatable weld sequences with minimal operator oversight

- Eliminated manual weld handling on large parts, improving safety

- Reduced rework and improved first-pass weld quality via recipe control and maintenance routines

- Operated across multiple shifts with only 1–2 operators managing load/unload

By combining automated torch maintenance, precision positioners, and dual-zone welding stations, MWES enabled faster pipe fabrication, greater safety, and consistent quality in heavy-duty welding operations.