The Challenge

Tackling Complex Panel Welding in a Labor‑Constrained Rail Environment

Welding large corrugated steel panels with integrated framing is challenging due to part size and weld complexity. The manufacturer faced:

- High demand for large-scale panel assemblies containing embedded window frames and structural beams

- A shortage of skilled welders capable of handling this complex, repetitive work

- Need for weld consistency and throughput in a paced production cell

MWES was selected to deliver a robotic laser welding solution that combined precision, high throughput, and minimal operator oversight.

The Solution

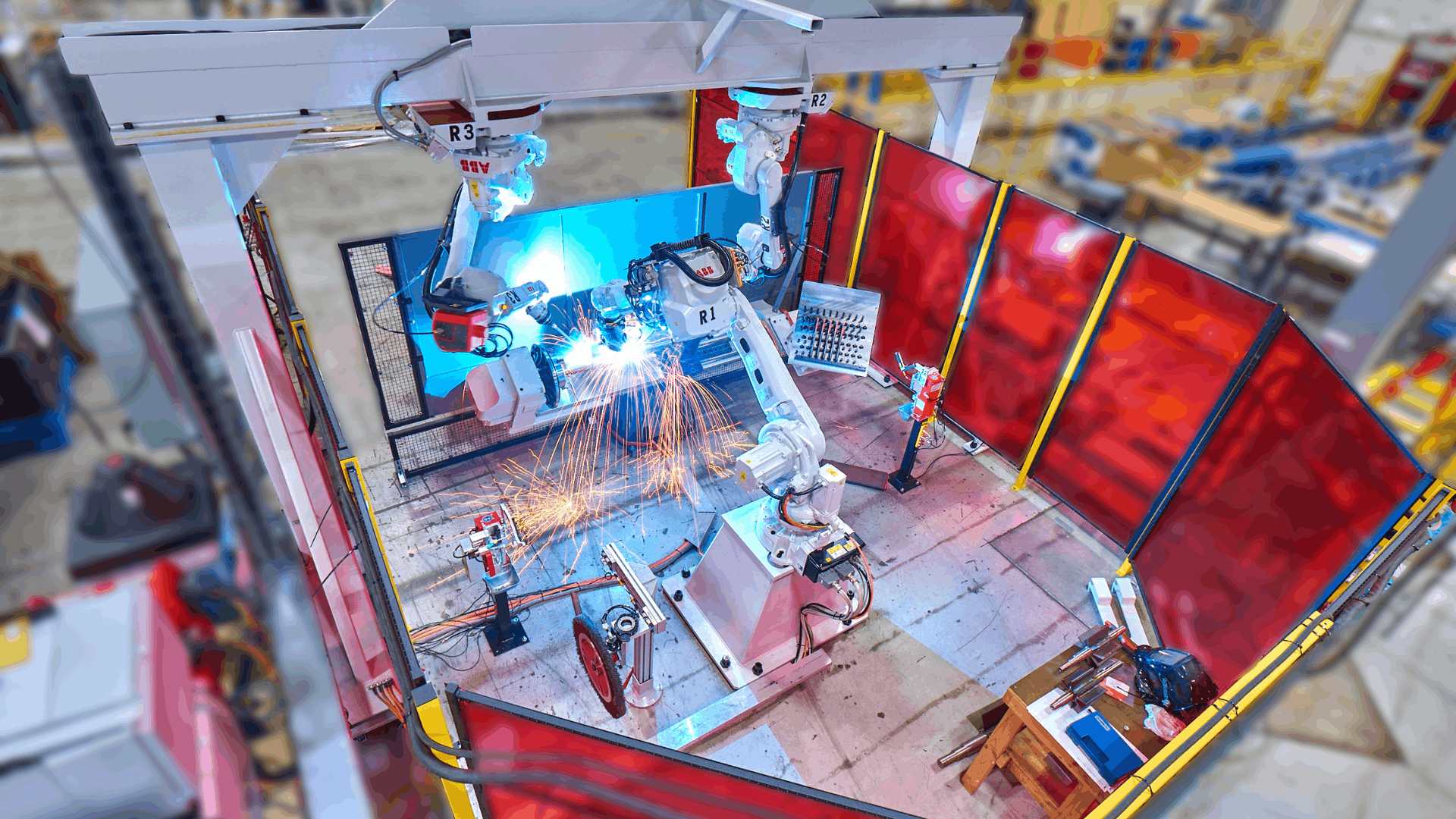

Gantry Robot & Overhead Laser Welding Cell for Reversible Panel Welding

MWES engineered a large-scale gantry system featuring:

- A Gudel 6-axis overhead gantry robot with a laser welding head, controlled via KUKA

- Ability to process up to four wall-panel assemblies in sequence as operators load and prep each model

- Operators load stiffeners, window frames, and top/bottom corrugated panels into a clamped top frame

- System can flip panels mid-process, enabling backside weld operations

- Includes integration of vertical beam and side pillar welding post panel seam process

This automated cell enables continuous high-precision welding feed across full panel geometries with minimal manual weld labor.

Summary: The gantry-mounted laser welding system allows multiple panel assemblies in sequence, including front and back welding operations—delivering consistent, high-speed rail car panel fabrication.

The Results

Consistent Multi‑Panel Throughput with Reduced Labor and Weld Quality Assurance

The completed system provided measurable outcomes:

- Automated welding of large-scale panels in additive sequence—processing up to four assemblies per cycle

- Enabled reversible panel welding (front/back) without manual repositioning

- Freed operators from hot, repetitive welding tasks—requiring simple part loading and unloading

- Delivered consistent weld depth and quality across complex geometries

By integrating laser welding with gantry and flip capabilities, MWES helped the customer achieve high-volume, reliable panel production while aligning to labor constraints and quality demands.