The Challenge

Heavy Roll Handling & High-Volume Polyethylene Bag Production

Working with 56″ wide film rolls weighing over 2,500 lb created ergonomic and throughput constraints. The customer required a solution to:

- Safely lift and load oversized rolls into the unwind station

- Process dual rolls automatically through unwinding, guiding, perforating, sealing, and bag output

- Support multiple bag widths (8″–53″) and film thicknesses (1–6 mil)

- Reduce operator strain and simplify roll changeovers

MWES was selected due to its decades of experience in web handling systems for converting and packaging applications.

The Solution

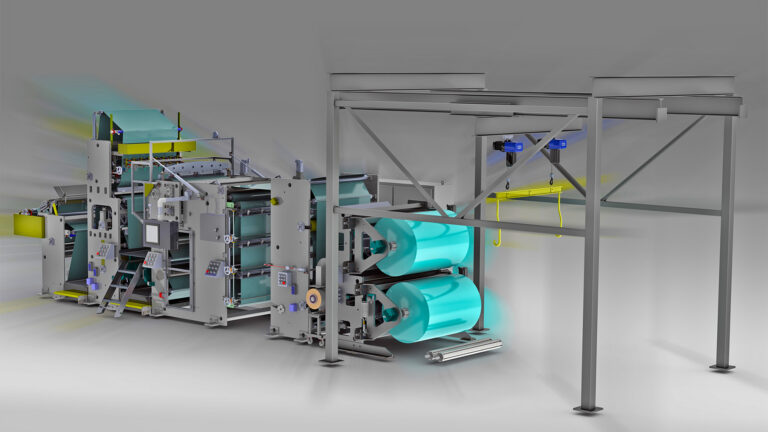

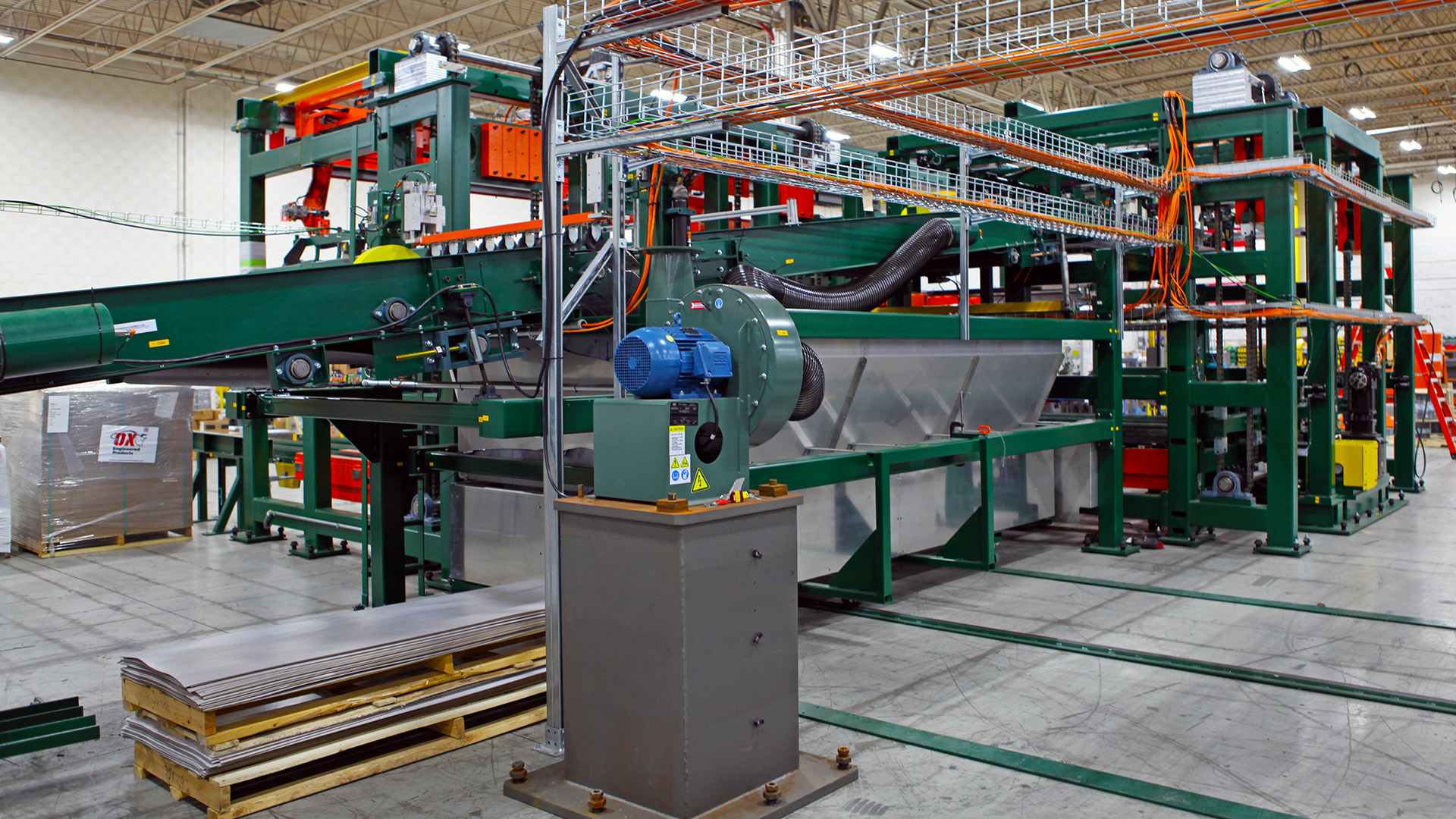

Overhead Gantry Roll Loader Integrated with Web Sealing & Bag Output

MWES delivered a comprehensive system with:

- Overhead gantry and motorized spreader bar to place full rolls onto unwind spindles safely

- Dual-roll unwind feeding into a combined web register and nip-feed assembly

- Vertical perforation and heat-sealing modules for precise bag formation

- Inspection blower box and pull-roll tensioning before micro-perforated bag separation

- Automated layer stacking of bags into shipping containers

This gantry-integrated web line automates roll loading, bag formation, and output into containers—all with minimal operator input.

Summary sentence: The gantry roll loader simplifies heavy film handling and feeds a high-speed, multi-size web process—delivering ergonomic safety and production efficiency.

The Results

Safe, High-Speed Bag Output with Reduced Manual Labor & Downtime

Key performance outcomes included:

- Bag production rate between 42–132 bags per minute, depending on size and speed Midwest Engineered SystemsMidwest Engineered Systems+2Midwest Engineered Systems+2

- Eliminated manual unloading and loading of heavy rolls via gantry-assisted automation

- Smooth roll changeovers and consistent bag quality across a range of sizes

- Reduced operator fatigue and improved safety during material handling

By integrating automated roll loading with advanced web handling and sealing modules, MWES enabled scalable, high-throughput bag making while reducing physical labor and downtime.