The Challenge

Coating and Laminating Thin Films into Ready-to-Use Tape Rolls

This customer required a continuous process to convert extruded material into adhesive tapes. The specific needs were:

- Cooling the extruded web from the extruder

- Treating both sides of the web before dual coatings

- Applying silicone to one side and adhesive to the other

- Laminating a release liner and automatically winding rolls on 3″ cores

MWES was selected to design an automated web handling and converting machine capable of integrating all these operations into a single efficient line.

The Solution

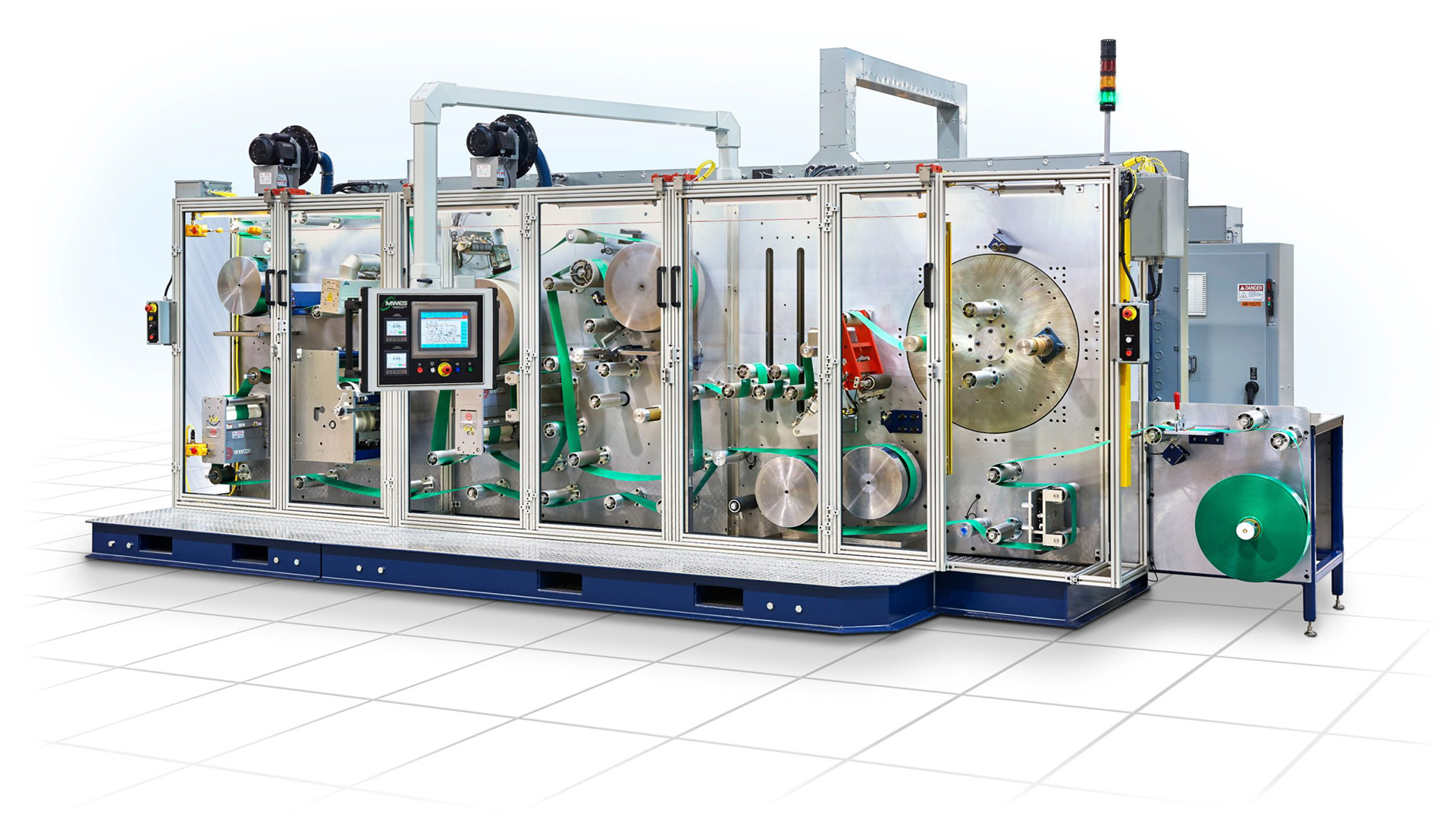

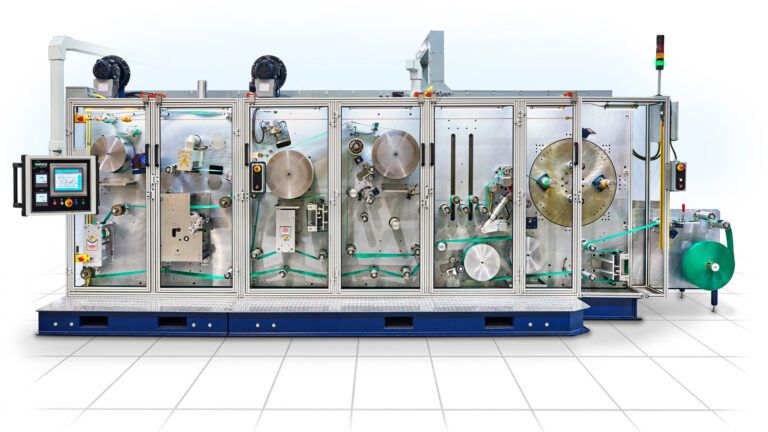

Modular Web Line with Coating, Liner Lamination & Automated Wind-Up

MWES engineered a custom four-section adhesive tape line:

- Chill section to cool the extruded film

- Rewind & accumulator that holds about 108 inches (~9 seconds at 60 FPM) of web for speed consistency

- Liner unwind & laminating section to laminate a release layer underneath the adhesive coating

- Treatment & adhesive coating section to apply silicone and adhesive coatings in sequence

- Built-in provision for future addition of printing equipment

MWES delivered a modular, high-speed coating and laminating cell that handles web treatment, dual coatings, and release-liner lamination—all with continuous winding and uniform control.

The Results

High-Speed Coating Line, Ease of Operation & Future Upgradeability

This turnkey system provided measurable improvements for the customer:

- Runs reliably at speeds of 60 ft per minute with smooth web control

- Simple maintenance and operator interfaces improve uptime and usability

- Easily upgradable—capable of integrating downstream printing or converting stations

- Consolidated multi-step production into one automated cell, reducing manual labor and complexity

By integrating multiple processes—cooling, coating, laminating, and winding—into a single high-throughput line, MWES helped the customer streamline adhesive product conversion, boost production speed, and ensure future adaptability.