The food packaging industry faces unique and growing pressures — rising consumer demand, evolving product formats, tightening labor markets, and ever-stricter food safety standards. To stay competitive and profitable, manufacturers must find ways to improve efficiency, maintain consistent quality, and reduce costs without compromising food safety or regulatory compliance.

Robotic automation is emerging as a strategic tool that addresses these challenges head-on by bringing precision, flexibility, and reliability to food packaging processes that were once heavily dependent on manual labor.

Increased Throughput and Productivity

Manual packaging processes can become bottlenecks as volumes grow. Robots excel in repetitive, high-volume tasks — working consistently around the clock, minimizing variability, and delivering predictable output. Automated systems can handle sorting, case packing, sealing, labeling, and palletizing at speeds that far exceed manual methods, allowing companies to increase throughput without proportional increases in labor costs.

Improved Accuracy and Product Consistency

In food packaging, consistency isn’t a luxury — it’s a requirement. Humans inevitably introduce variability, especially in repetitive tasks like filling, sealing, and labeling. Robotic automation eliminates much of that variability by performing tasks with repeatable precision, which can improve fill accuracy, reduce defects, and support stricter quality control. This consistency helps reduce product waste and enhances consumer confidence in food quality and safety.

Flexibility to Meet Changing Demands

Food manufacturers often package a wide range of products — from dry goods to fresh produce to prepared meals — each with distinct sizes, shapes, and packaging requirements. Modern robotic systems are equipped with advanced sensors, vision systems, and adaptable tooling that can quickly switch between product formats and configurations. This adaptability makes it easier for companies to respond to shifting market demands without costly line retooling.

Enhancing Workplace Safety

Food packaging work can involve heavy lifting, repetitive motion, and exposure to hazardous conditions. By assigning these tasks to robots, companies can reduce the risk of workplace injuries and fatigue-related errors. Reducing physically demanding work helps protect employees and can also reduce unplanned downtime, insurance costs, and compliance risk — all while making the workplace safer for human operators who focus on skilled tasks.

Reducing Costs and Supporting Sustainability

Although automating food packaging requires an upfront investment, the long-term benefits can be significant. Robots reduce reliance on manual labor, trim material waste through precise dispensing and handling, and can optimize energy use — contributing to lower operating costs and improved return on investment. More efficient use of packaging materials and reduced rework also support sustainability goals by lowering environmental impact.

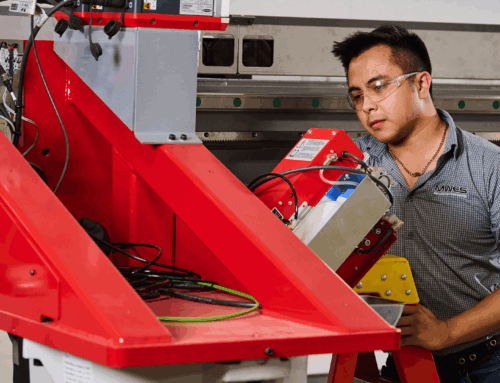

How MWES Supports Food Packaging Automation

Midwest Engineered Systems combines food and beverage industry expertise with deep systems integration experience to help manufacturers modernize packaging operations. From robotic case packing and automated wrapping to hygienic material handling and traceability solutions, MWES designs automation systems that:

- Improve production efficiency without compromising food safety

- Enhance quality and consistency across packaging lines

- Support flexible, changeover-ready production

- Reduce dependence on hard-to-fill labor roles

- Align with sanitary and regulatory requirements

Robotic automation isn’t a trend — it’s a practical strategy for food manufacturers seeking to drive throughput, improve quality, and build competitive advantage in a dynamic market.

Learn More About Food Automation Solutions

If your operation depends on manual packaging processes or is struggling to keep up with demand, explore how MWES can help design and implement tailored robotic automation that meets your needs and supports future growth.

Contact us to discuss your automation goals and start building a more efficient, adaptable food packaging operation.