The Challenge

Modernizing a 1990s Vacuum Coating System for Performance and Uptime

The customer needed to bring an aging vacuum metalizer up to modern standards without investing in a full system replacement. Key goals included:

- Replacing obsolete components and software across drives, PLCs, and controls

- Improving machine accessibility for maintenance and troubleshooting

- Expanding speed range and recipe flexibility for a wider material set

- Enabling modern quality control through better system monitoring

The customer chose MWES for our deep expertise in web handling upgrades and ability to retrofit legacy OEM machines with custom solutions.

The Solution

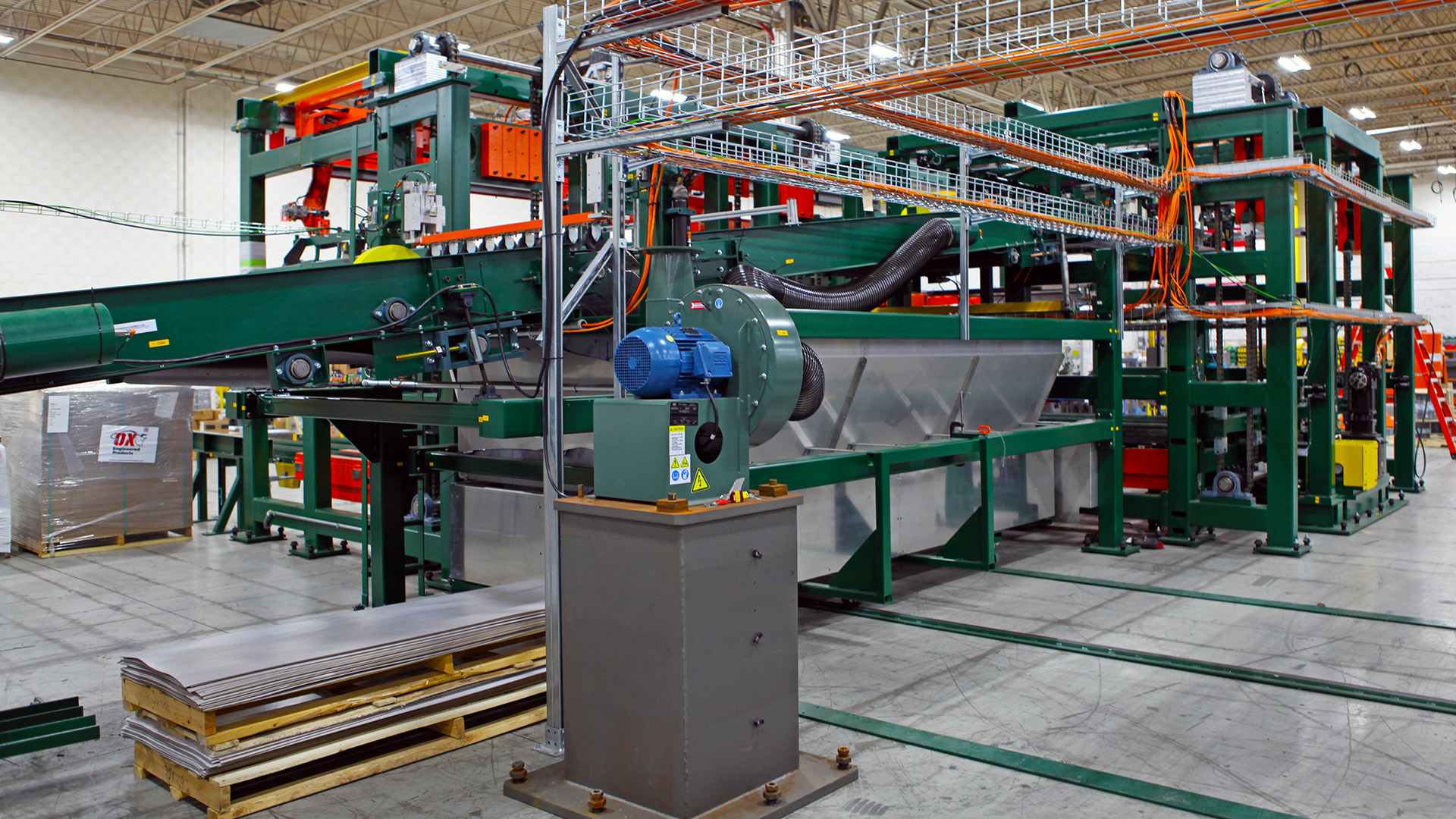

Complete Controls Overhaul and Motion Upgrade with Remote Access Capability

MWES engineered and installed a comprehensive controls and motion system retrofit, including:

- New Bosch-Rexroth AC drive platform, gearboxes, and motors for web handling

- Allen-Bradley ControlLogix PLC with Ethernet & Profibus networked control

- Custom-coded replacement of OEM software using PLC-integrated logic

- FactoryTalk View SCADA HMI system for multi-location operator access

- Danaher Micro-Stepper drives for precision wire feed control

- Integrated pump controls and custom heater monitoring logic

- Offsite simulation and pre-testing to reduce on-site commissioning time

The system was fully installed and commissioned on-site by MWES with minimal disruption to production schedules.

The Results

Expanded Coating Capabilities and Improved Control Through Automation

The MWES retrofit provided immediate and long-term benefits:

- Wider process range from 0.5 to 100 FPM for new coating applications

- Easier engineering access and troubleshooting via updated controls

- Increased quality control through improved monitoring and remote system access

- Future flexibility for system expansion and recipe customization

With modern controls, enhanced diagnostics, and improved user interfaces, the upgraded system brought new life to a critical production asset—delivering reliable performance and greater operational insight.