The Challenge

Safely Storing and Retrieving 200-Pound Laminate Rolls in Limited Space

This customer faced a materials handling and storage challenge with large laminate rolls that were difficult and dangerous to move manually. Their goals included:

- Automating the retrieval of 62″ rolls weighing up to 200 pounds

- Navigating a compact racking system with robotic precision

- Presenting rolls at a cutting station for operator access

- Minimizing manual handling to reduce labor strain and injury risk

MWES was tasked with engineering a robotic system that could reliably store and retrieve hundreds of heavy rolls while fitting within a constrained footprint.

The Solution

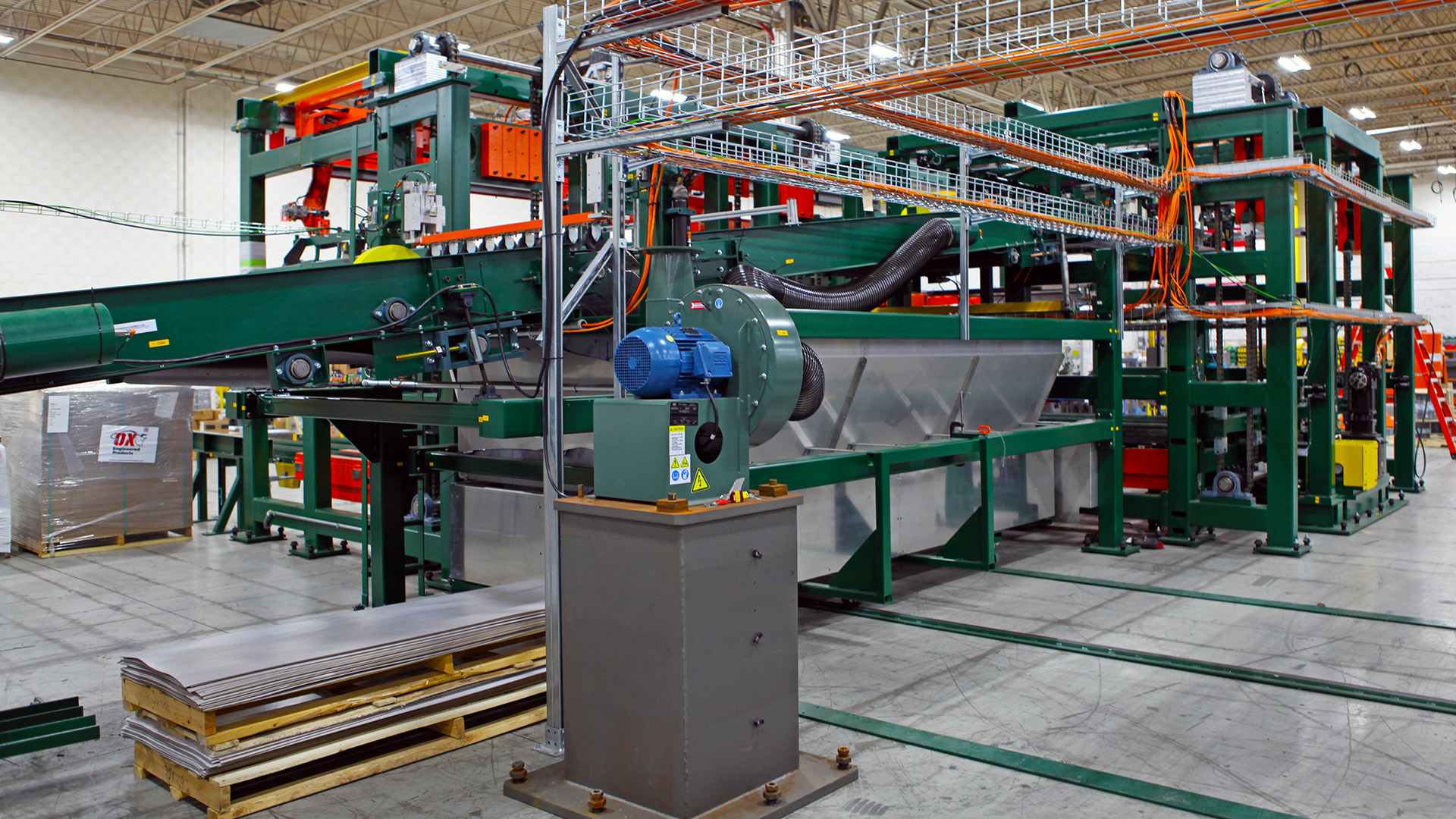

Robotic Roll Storage with Automated Retrieval and Operator Presentation

MWES engineered a custom roll storage and cutting system featuring:

- Robotic retrieval of up to 720 laminate rolls from a dense racking system

- Wonderware-based operator interface for order selection and system control

- Intelligent pick strategy to evenly distribute load across the rack

- Automated presentation of rolls to the operator for unwinding and manual cutting

- “Make-ready” staging of the next roll to minimize downtime between cuts

- Automatic return of used rolls to original storage positions

This high-efficiency system provided a seamless process from order to cut, ensuring continuous operation with minimal operator intervention.

The Results

Increased Efficiency and Reduced Manual Labor for Heavy Roll Handling

The MWES system delivered measurable improvements in throughput and safety:

- Automated storage of up to 720 rolls in a compact footprint

- Cycle times up to 2.5 minutes, with faster access for rolls near the cutter

- Reduced manual handling of 200-pound rolls, improving operator safety

- Enhanced productivity with continuous roll retrieval and staging

By integrating robotics and intelligent controls, MWES helped the customer maximize floor space, minimize handling risks, and streamline their laminate sheet production process.