The Challenge

Safely Handling and Palletizing 6,000‑lb Rolls Without Manual Strain

The customer needed to automate the cumbersome process of moving cylindrical heavy rolls, orienting them for transport, and preparing them for shipment:

- Stretch-wrapping large rolls while on their side

- Up-ending rolls safely and accurately onto pallets

- Automating weight verification and palletizing

- Feeding wrapped pallets seamlessly into labeling and forklift staging

MWES was tasked with designing a system to handle these heavy rolls efficiently, safely, and within an existing facility layout.

The Solution

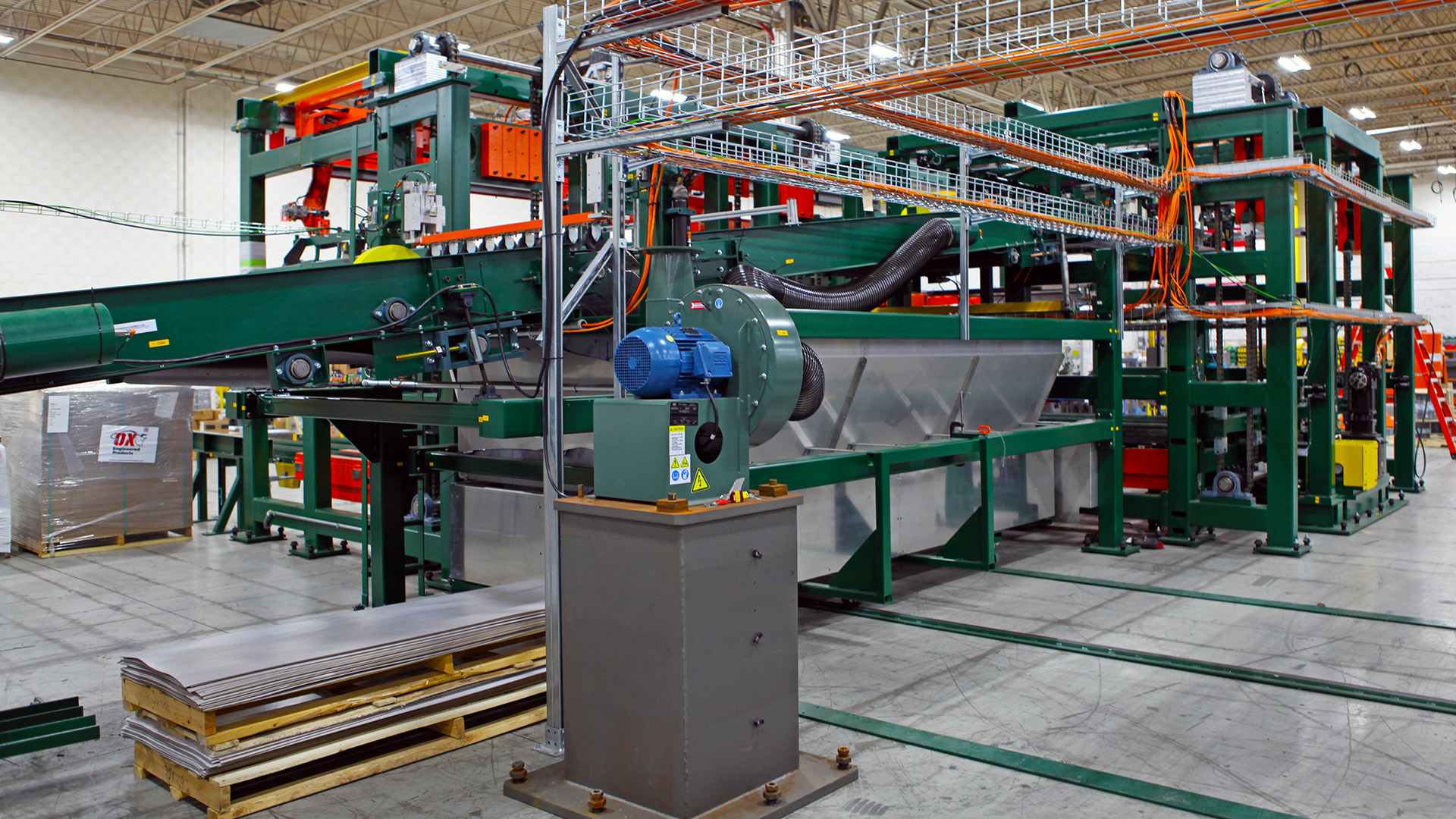

Integrated Conveyance, Wrapping, Up‑Ending & Labeling Automation

MWES developed a complete handling solution that automatically wraps, positions, up-ends, weights, labels, and queues roll-laden pallets:

- S-2500 Trundle Wrapper secures the roll while still horizontal

- Gravity ramp and up-ender tilt the wrapped roll onto pallet—without human force

- Pallet dispenser/clamp system positions pallet for inbound roll

- Weight scale and conveyors transport pallet for verification

- S-1500 Stretch wrapper and conveyor turntable wrap and label pallet

- Discharge conveyor positions final pallet for forklift pickup

This cohesive system eliminates manual lift requirements and ensures consistent roll orientation, wrapping, and pallet readiness.

The Results

Streamlined Roll Logistics with Major Safety Gains and Throughput

MWES’s automation solution delivered quantifiable operational improvements:

- Safe handling of rolls up to 6,000 lbs without manual lifting

- Consistent stretch wrapping and secure palletizing every cycle

- Automated roll orientation and weighing quality control

- Reduced risk of injury and fatigue for operators

- Elevated output with repeatable, reliable process integration

By combining wrap, conveyance, orientation, and labeling into one automated workflow, MWES enhanced safety, efficiency, and roll logistics performance for the facility.