The Challenge

Reducing Labor Strain in High-Volume Part Unpacking & Orientation

Manual unpacking and handling hundreds of small parts per layer across multiple pallet levels was labor-intensive and ergonomically demanding. The customer sought a robotic solution to:

- Eliminate manual unpacking of layered part trays and packaging

- Precisely unload 128 sprayer nozzles per tray with mixed orientations

- Place parts in correct orientation for downstream assembly

- Automate separation and disposal of cardboard and thermoform packaging

MWES was selected to design an integrated system that could increase speed, reduce labor, and improve part flow to assembly operations.

The Solution

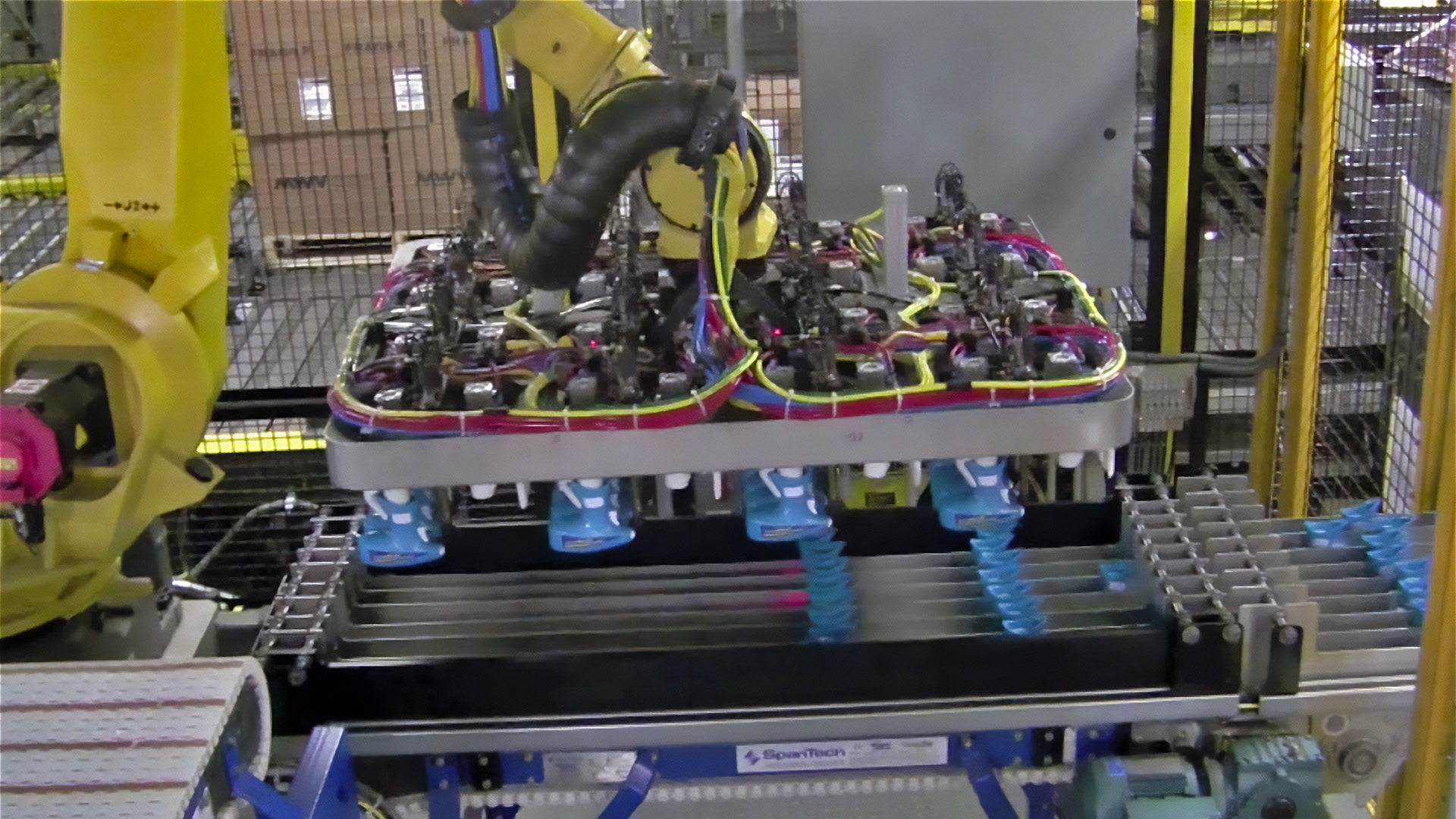

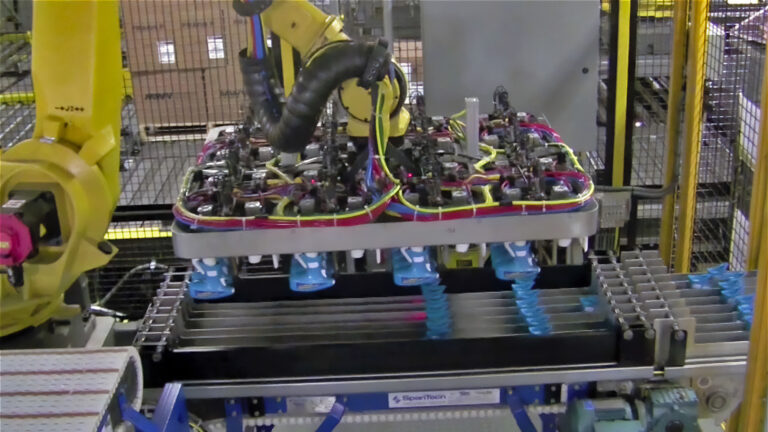

Dual-Robot Cell for Unpacking, Orienting, and Transfer to Conveyor

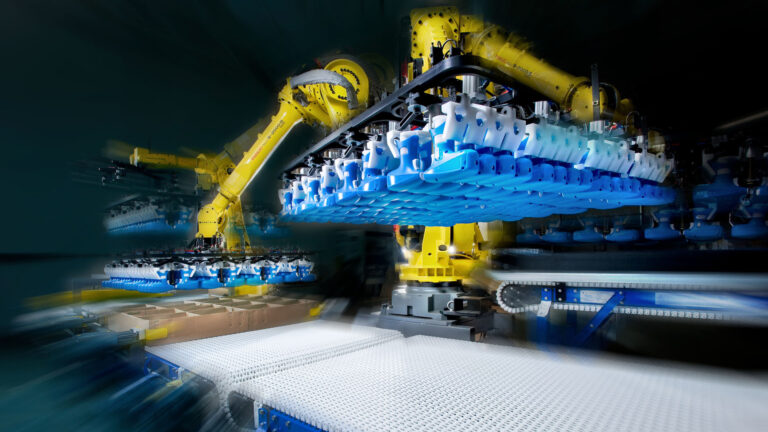

MWES engineered a robust automation system with two FANUC robots, layered material handling, and a custom lane-merging conveyor solution.

- Robot #1 removes tray covers, internal dividers, and stacks flattened packaging for recycling

- Robot #2 picks all 128 parts at once and deposits them into an 8-lane separation conveyor

- Automated 16-layer pallet stripping and tray handling to minimize operator input

- Corkscrew conveyor merges all lanes into single file for downstream assembly

- Plastic trays are removed and stacked for reuse or recycling

The robots work in tandem to manage full tray unpacking and high-speed part delivery, minimizing handling time and maximizing system uptime.

The Results

Faster Unpacking, Improved Orientation & Reduced Manual Labor

The MWES robotic system transformed a manual, multi-step process into an efficient, high-speed automated operation:

- Unpacked and sorted 128 parts per tray with precise orientation

- Achieved smooth, single-operator supervision for full material flow

- Enabled reuse or recycling of packaging with automated segregation

- Reduced labor and improved ergonomics by eliminating repetitive tasks

This robotic solution streamlined unpacking and part preparation, enabling the customer to scale production without increasing labor.