The Challenge

Eliminating Manual Lifting While Maintaining Bending Flexibility

Manual press brake operation posed ergonomic issues and limited productivity. The customer needed an automation solution that could:

- Handle a wide range of part sizes and weights (up to 500+ lbs)

- Automate multi-bend operations with high precision

- Reduce operator strain and eliminate lifting hazards

- Integrate with the existing Bystronics press brake

MWES was selected for their ability to deliver a fully automated, flexible press brake tending system that could reduce labor dependency while maintaining part accuracy.

The Solution

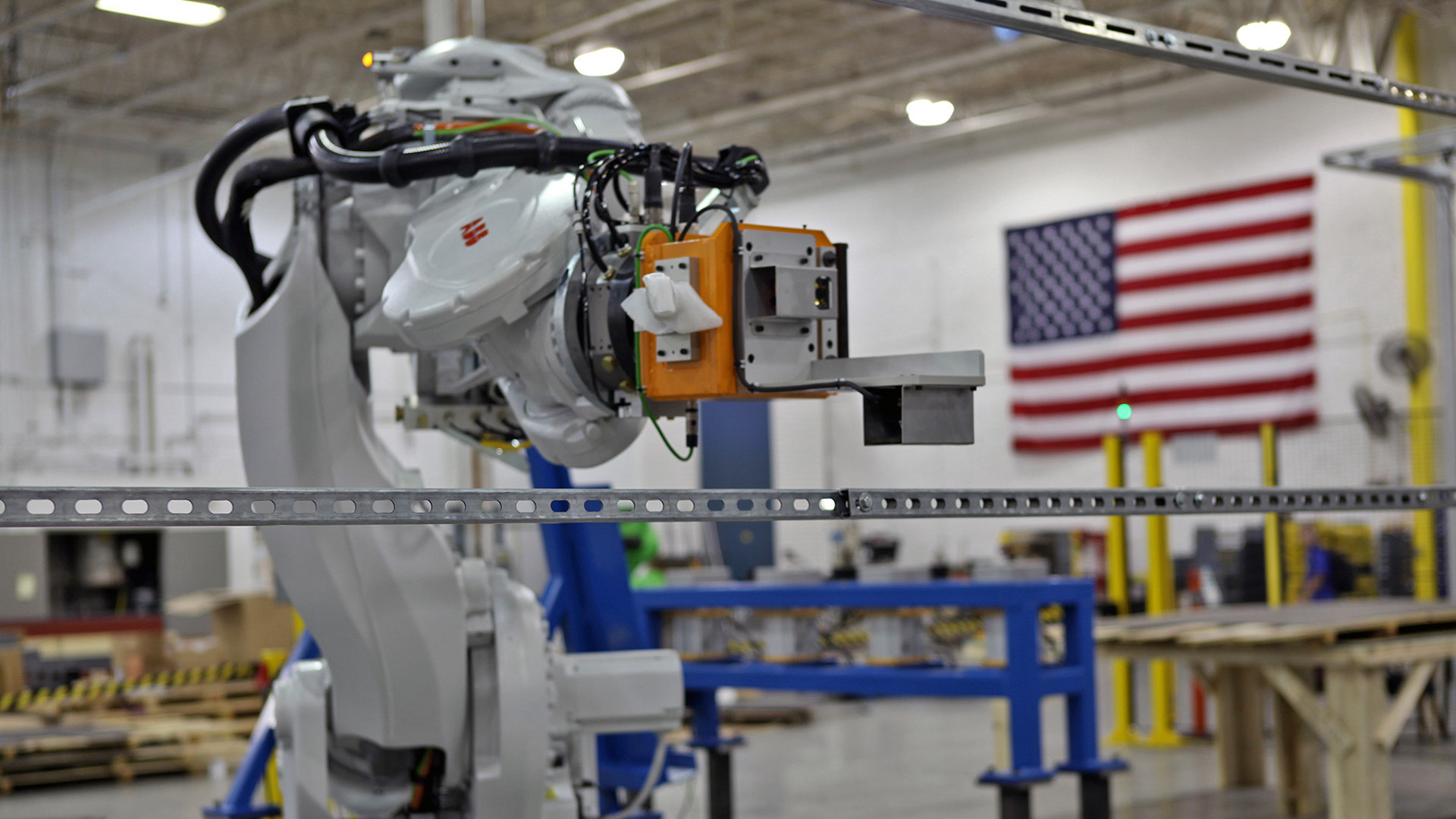

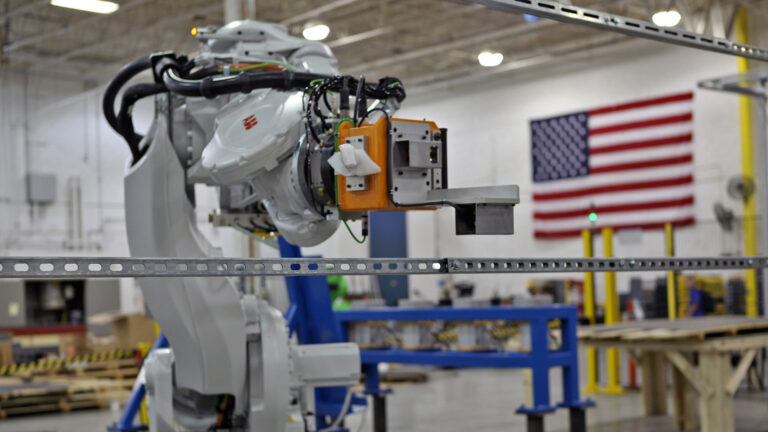

Flexible Robotic Tending Cell with Vision-Guided Squaring

MWES delivered a custom robot-tended press brake cell featuring:

- ABB IRB 7600-500/2.55 robot mounted on a floor-mounted 7th-axis track

- Automatic tool changer with three custom gripper EOATs

- Cognex overhead vision system for part identification and squaring

- Squaring station and part thickness sensors for accuracy

- Regrip station for multi-bend handling and dual outfeed zones

- Safety light curtains, interlocks, and IRC5 robot interface for operator control

This robotic cell provided the flexibility to bend large parts safely and repeatedly with minimal human input, increasing efficiency and quality.

The Results

Increased Productivity with Reduced Labor and Safer Operations

The MWES solution delivered measurable improvements across the board:

- Enabled single-operator supervision of the entire bending process

- Improved bend quality and consistency with vision-guided alignment

- Reduced physical strain and risk of injury from heavy lifting

- Increased throughput while minimizing manual intervention

By automating the press brake operation, MWES helped the customer improve productivity, reduce operator fatigue, and achieve consistent, high-quality part output.