The Challenge

High-Mix Cylinder Head Post‑Process Handling Without Manual Bottlenecks

Manual handling of cylinder heads post-machining was labor-intensive and inconsistent. The customer needed automation that would:

- Handle four different cylinder head models seamlessly

- Automate cleaning, peening, plug insertion, inspection, and cooling

- Integrate into an existing assembly line without disrupting flow

- Provide consistent cycle times and reduce operator touchpoints

MWES was selected to deliver a turnkey robotic system that would streamline post-machine finishing while maintaining quality and throughput.

The Solution

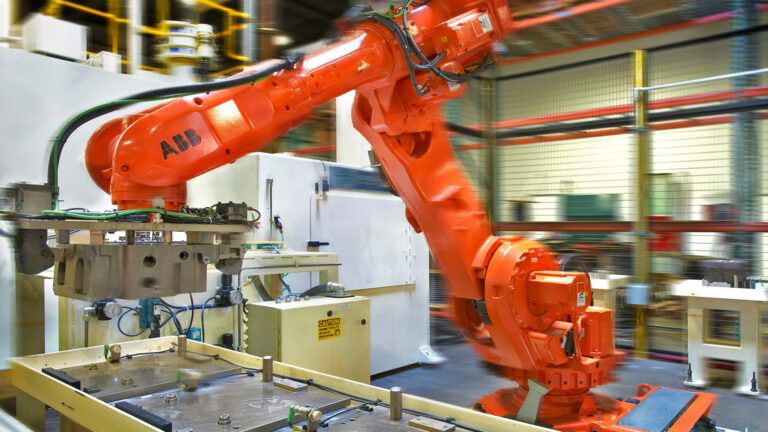

Track-Mounted Dual-Robot Cell with Vision Control and Integrated Finishing Stations

MWES designed a robotic cell incorporating:

- Track-mounted robot that scans part ID via Cognex vision then routes head to cleaning station

- Dual-part heated washer (140‑150 °F) for coolant and debris removal

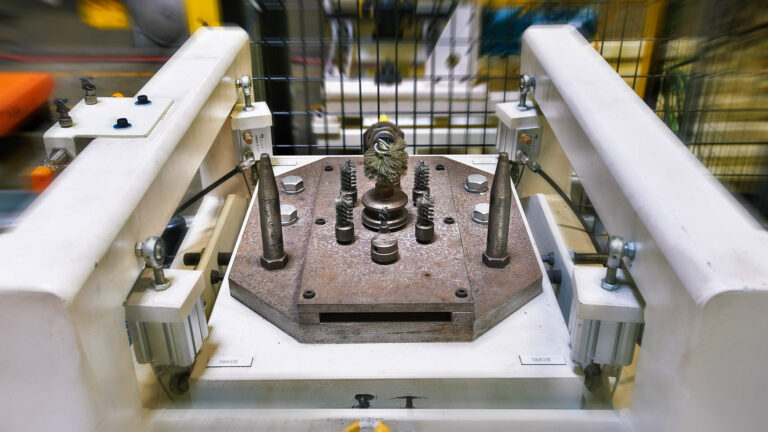

- Shot peen robot with plug-in inspection and quality check stations

- Post-peen wash and drying station with integrated chemical treatment

- Cooling rack with flip and final transfer to outfeed conveyor

This solution handles all finishing steps in a unified cell—automating cleaning, inspection, and delivery while supporting high-mix throughput with minimal operator involvement.

The Results

Consistent 3-Minute Cycle and Single-Operator Continuous Operation

The automated finishing line delivered efficiencies across the board:

- Maintained a 3‑minute average cycle time per cylinder head

- Handled multiple part types without manual reprogramming or changeover

- Streamlined operations so a single operator can oversee continuous flow

- Delivered higher quality, traceable inspection, and reduced handling variability

By automating this complex post-machining flow, MWES enabled the customer to scale throughput, improve consistency, and reduce labor dependency across their cylinder head finishing operations.