The Challenge

Handling High-Precision Press Assembly with Minimal Operator Strain

The manual assembly of flywheels was slow, varied in quality, and caused ergonomic strain. The customer required a system that would:

- Precisely press flywheel race bearings to specified force

- Flip heavy flywheels between operations routinely

- Maintain consistent cycle time (~50 seconds) and accuracy

- Minimize operator involvement and physical labor burden

MWES was selected to design a robust press automation system that would integrate handling, force feedback, and flip operations in one streamlined workflow.

The Solution

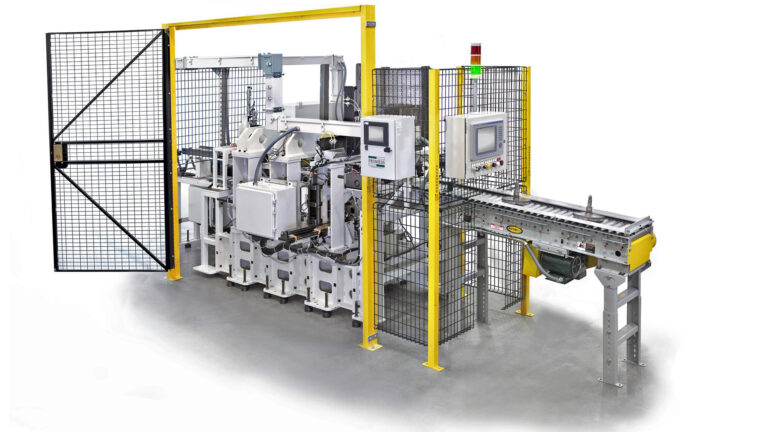

Multi‑Position Hydraulic Press Cell with Robotic Flip & Force Monitoring

MWES delivered a customized cell that includes:

- A chain conveyor belt for part infeed working in tandem with a clean parts washer

- Hydraulic press equipped with Promess force-monitoring system to ensure pressing accuracy

- Part flip mechanism to unload and reload flywheels without manual handling

- Integrated robotic logic to align, press, verify, and flip parts

- Simple operator stations limited to loading presses and removing finished flywheels

In summary, the fully automated press cell handles loading, force-verified pressing, flipping, and unloading with minimal operator engagement—ensuring clean, repeatable assembly.

The Results

Consistent 50‑Second Cycle with Reduced Labor & Improved Quality

Post-deployment, the system delivered:

- Reliable flywheel assembly in 50 seconds or less per unit

- Automatic verification of press force to eliminate assembly defects

- Operator relief from manual flips and load/unload handling

- Higher throughput and repeatability with fewer operators per shift

By automating pressing and flipping operations with integrated force feedback, MWES helped the customer boost both throughput and yield—while improving ergonomics and reducing operator fatigue.