The Challenge

Replacing Manual Lip Formation with High-Speed, Flexible Automation

Manually rolling the softened brim of plastic flower pots was slow, inconsistent, and physically demanding. The customer needed a system that could:

- Produce a consistent, rounded lip on each pot under 10 seconds

- Handle multiple pot sizes (four variants) without extensive changeover

- Maintain part integrity while forming features on soft plastic

- Reduce manual labor and ergonomic strain for operators

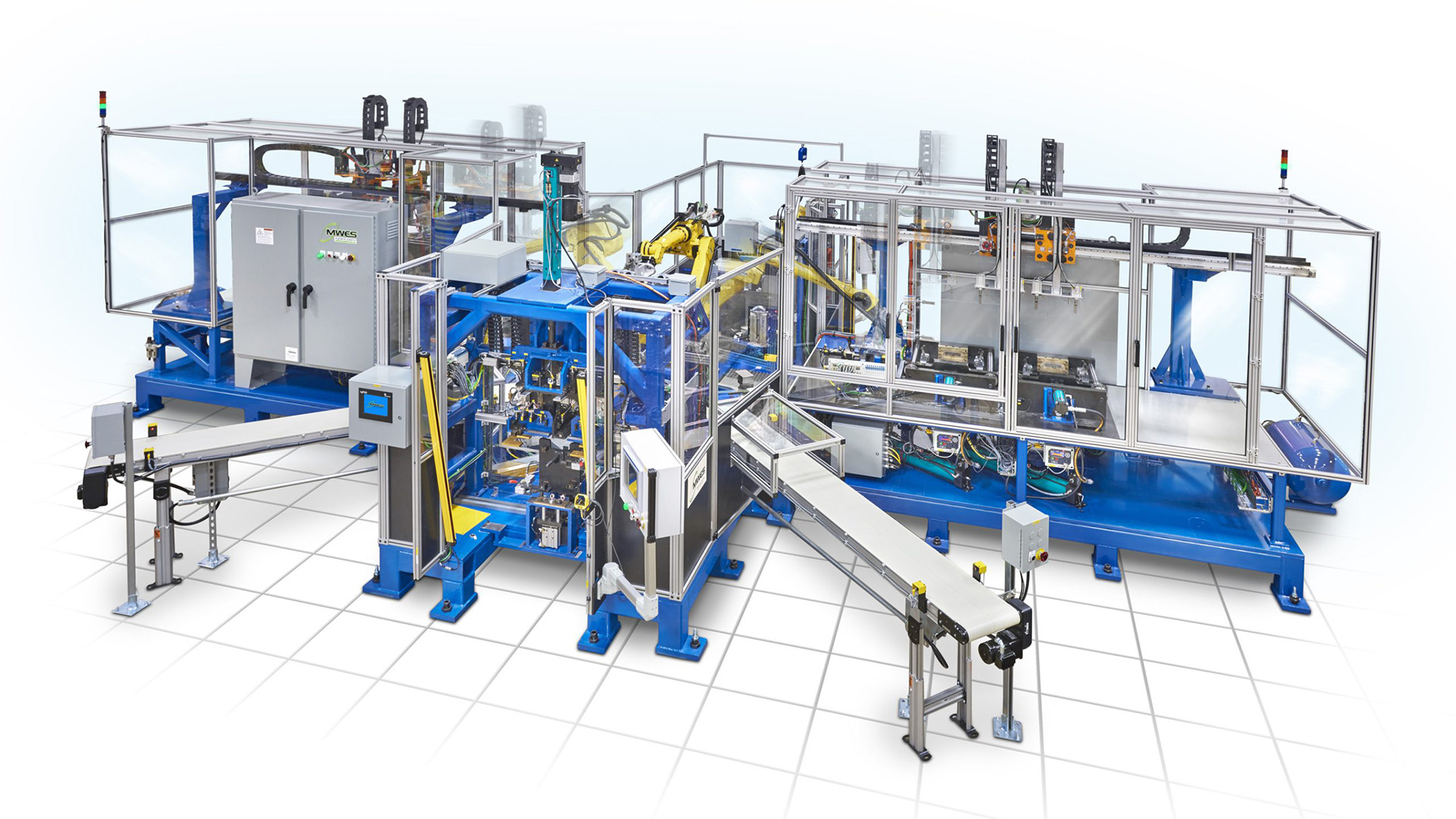

MWES was chosen for its ability to engineer precise forming automation that brought speed, repeatability, and flexibility to pot edge manufacturing.

The Solution

Turn-Tabled Rotary Machine with Automated Lip Forming via Clamped Pressure

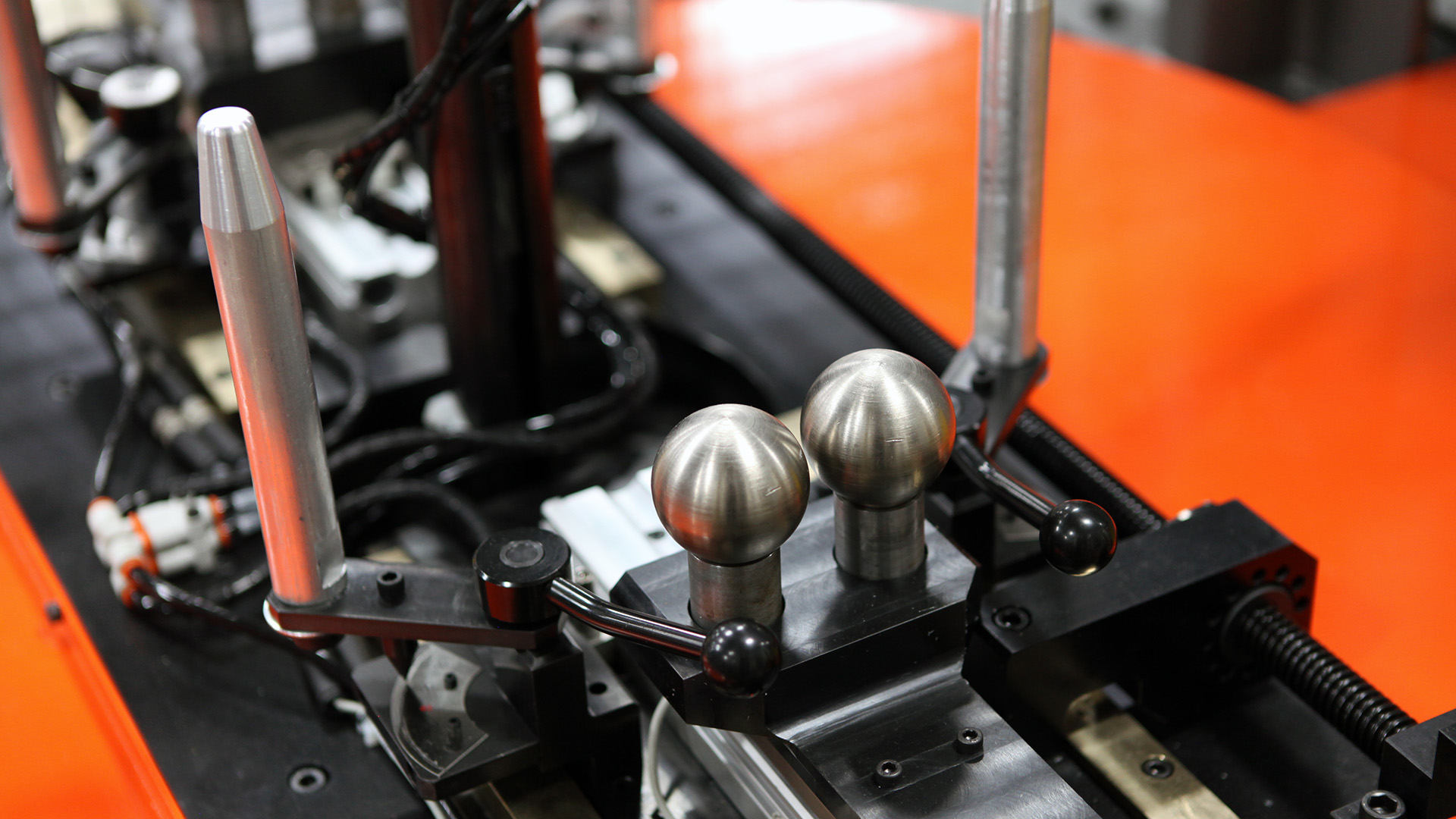

MWES designed and delivered a compact, high-efficiency edge rolling machine incorporating:

- A rotating turntable specific to flower pot form

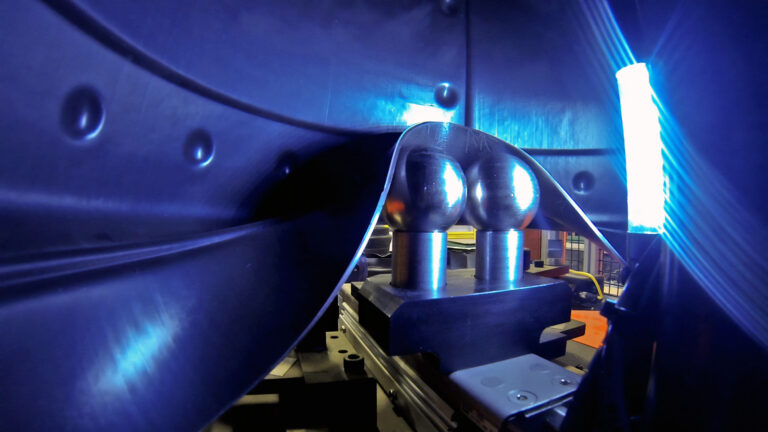

- Clamp-actuated lip rollers that press and form edges while the pot rotates

- Quick-change nests for four different pot diameters

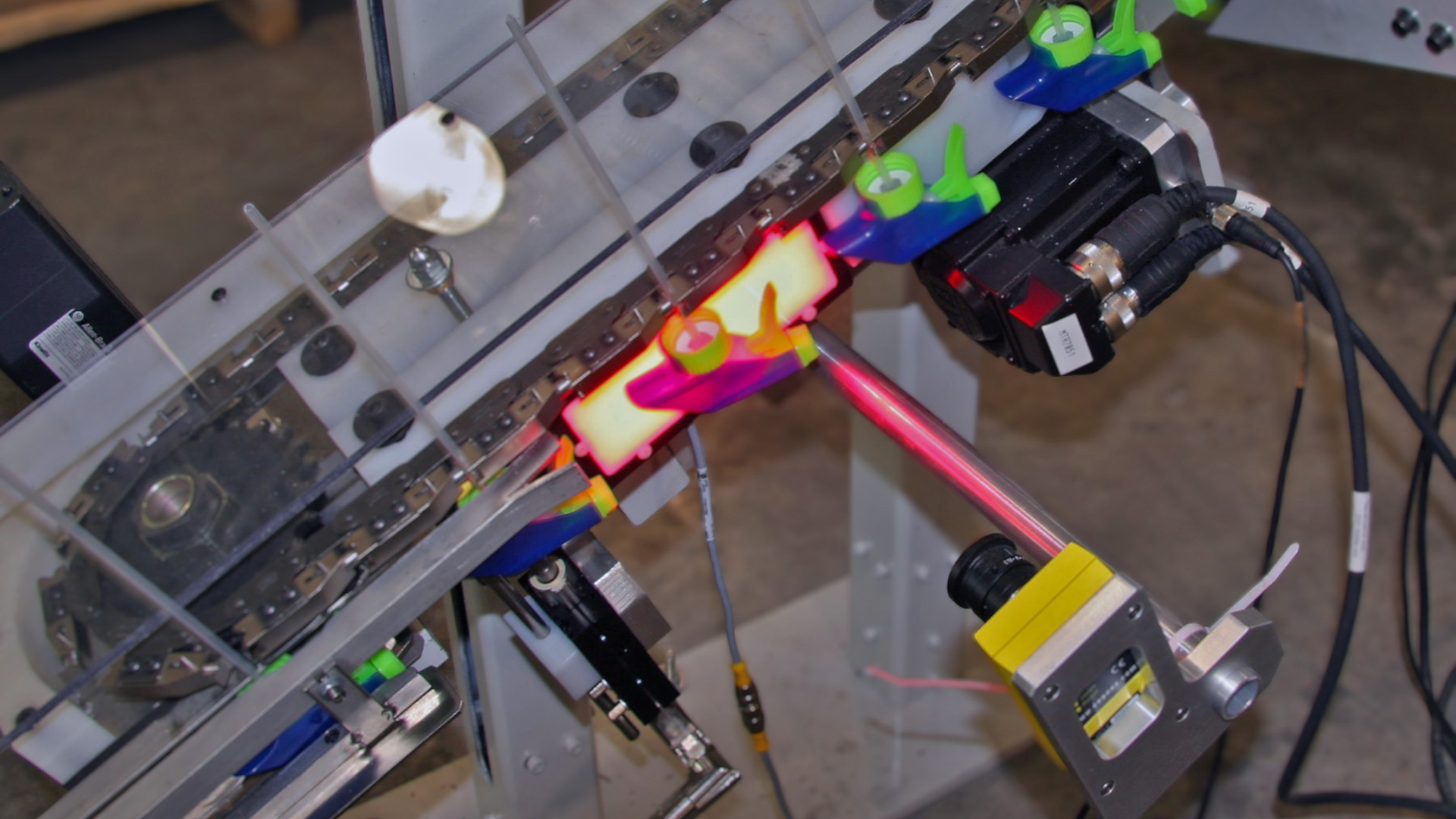

- Simple operator interface for pot loading, clamping, and cycle initiation

An operator loads a pot, secures it in the nest, and initiates the lip-forming cycle via HMI. The turntable rotates 360° while clamps apply pressure to form the uniform lip. Once complete (typically under 10 seconds), the operator opens the clamp and removes the pot. This streamlined format ensures fast, repeatable cycles with minimal operator input.

The Results

High-Speed, Precise Lip Rolling with Labor Efficiency and Throughput Gains

The automation system delivered significant performance enhancements:

- Average lip-forming cycle time of 10 seconds per pot

- Consistent, high-quality lip formation across all four pot sizes

- Eliminated manual force and error from a previously labor-intensive step

- Simplified changeovers between pot sizes using customizable nests

By removing manual lip rolling and incorporating user-friendly changeovers, MWES helped the customer improve throughput, reduce fatigue, and ensure product consistency.