The Challenge

Reducing Operator Dependency and Ensuring Fast, Error-Free Assembly

Relying heavily on manual labor for part assembly created staffing challenges and throughput inconsistencies. The customer needed an automation solution that could:

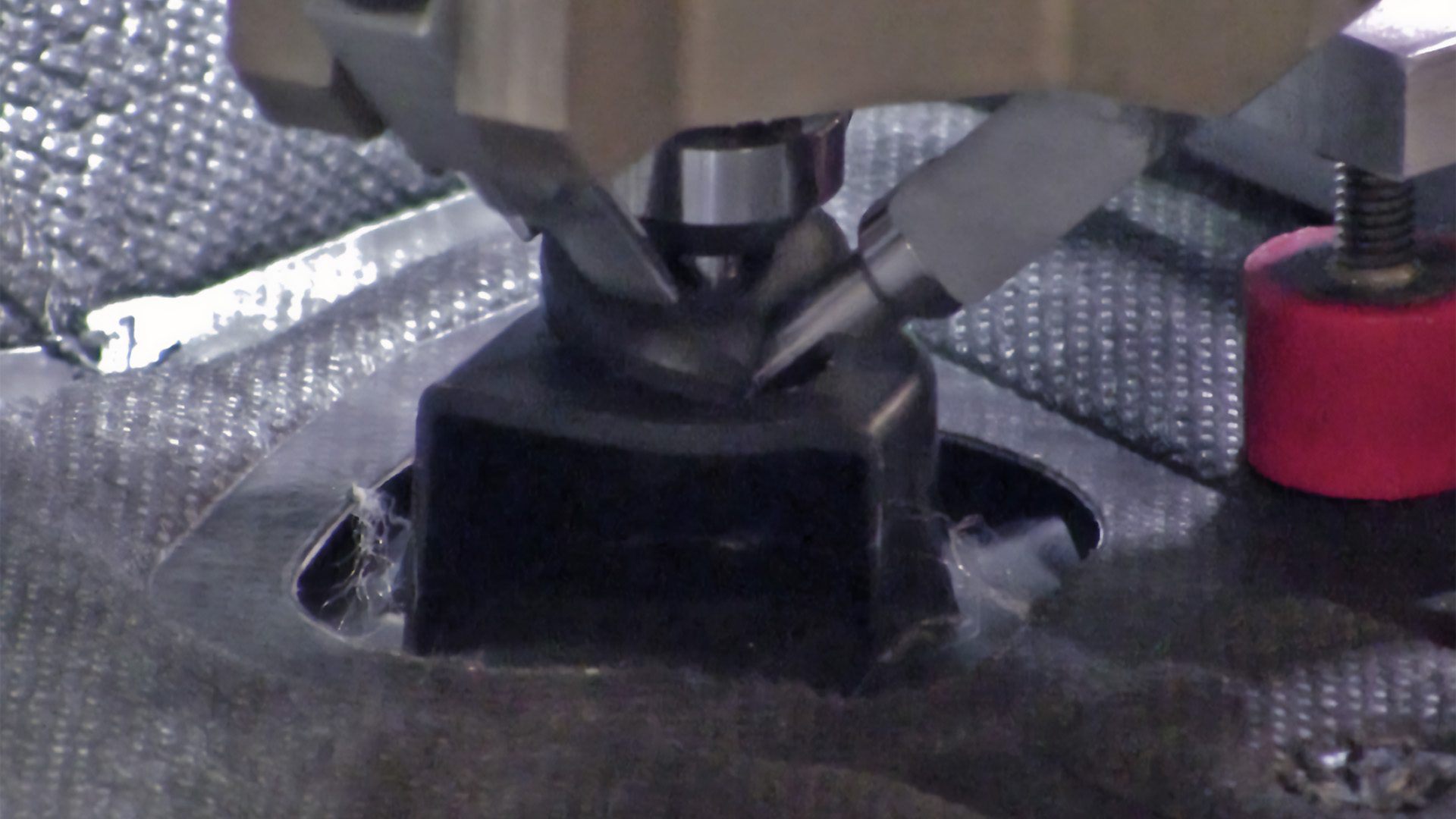

- Automate ultrasonic welding of acoustical materials into cover interiors

- Precisely insert rubber grommets and push nuts into pre-drilled holes

- Integrate vision-based inspection for final quality control

- Seamlessly reject failed parts while preserving production rate

MWES was selected based on its experience integrating robotic assembly, inspection, and defect handling in automotive environments.

The Solution

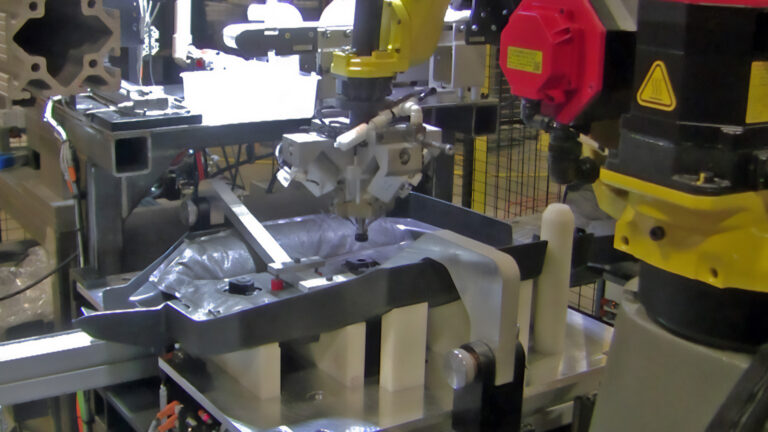

Multi-Robot Work Cell with Integrated Welding, Fastening & Vision Inspection

MWES engineered a comprehensive robotic automation cell featuring:

- Two Fanuc LR Mate 200iC/5L robots and one M10iA/10kg robot for ultrasonic welding, grommet insertion, and testing

- Flex‑Link pallet conveyor system to index engine covers through three robotic stations

- Ultrasonic welding to attach acoustical insert, followed by fastening grommets and push nuts

- Vision inspection via camera to conduct final pass/fail analysis

- Automated reject gripper to divert failed parts and unload good units to the exit station

The system orchestrates assembly, fastening, inspection, and rejection in a streamlined flow—reducing operator intervention and ensuring consistent quality.

Summary: This turnkey robotic cell automates all post-manual operations, combining ultrasonic welding, fastening, visual verification, and reject sorting in a fast and reliable production loop.

The Results

Consistent 60‑Second Cycle, Fewer Errors & Operator-Free Rejection

The implementation delivered measurable operational benefits:

- Achieved a reliable ~60-second cycle time per part

- Reduced dependence on manual labor while supporting high operator turnover

- Consistently accurate ultrasonic welds and fastener installation

- Automated quality inspection and reject handling without manual sorting

By automating critical assembly and inspection steps, MWES provided a high-throughput solution that improved reliability, reduced labor demands, and ensured consistent part quality.