The Challenge

Ensuring Leak‑Free Cooler Assembly in a High‑Volume Environment

Manual assembly, testing, and part handling introduced inconsistencies and production delays. The customer required an automated solution to:

- Precisely install dowels and O-rings into cooler housings

- Detect assembly quality and perform dual-stage leak tests (water and gas sides)

- Track parts via barcodes and handle rejects immediately

- Automate assembly flow across multiple stations without manual carryover

MWES was selected for their experience in robotic systems combining assembly, inspection, barcode traceability, and automated test stations.

The Solution

Single‑Robot Automation Cell with Multi‑Station Assembly, Testing & Torque Control

MWES engineered a full robotic cell featuring:

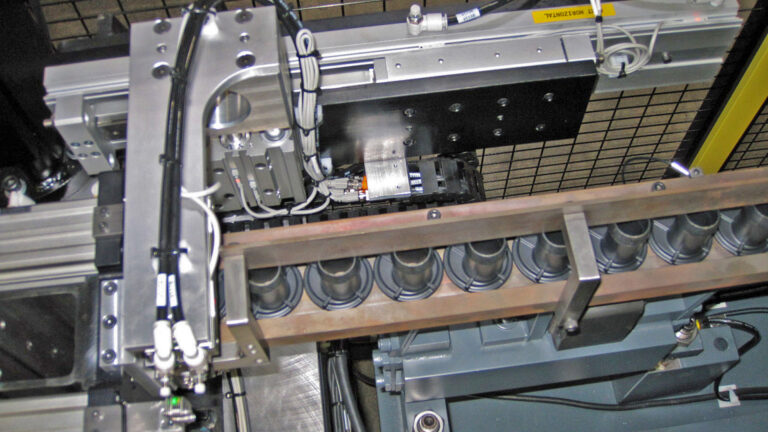

- Robot loading and transporting between dowel press station, O‑ring station, core‑shell marriage station, and leak test stations

- Semi‑automatic press fit for dowels and manual O‑ring insertion assisted by operator loading

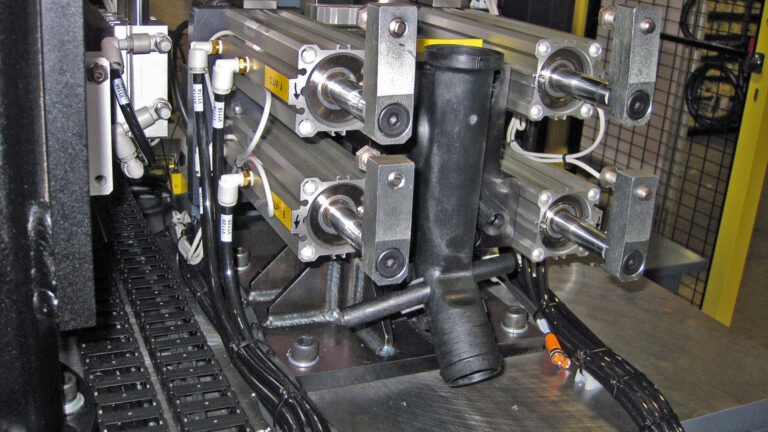

- Dual leak test stages with 20,000 lb press and pressure decay units for both water and gas sides

- Barcode tracking and automated reject logic with shuttle handling

- Torqued bolt tightening via dual‑spindle torque tools integrated into a 4‑stop indexing dial

Thanks to gantry-style robot handoffs and sensor integration, MWES delivered a fully automated production line that aligns assembly, test, reject handling, and torque control seamlessly.

The Results

Reliable 50‑Second Cycle Time, Traceable Quality & Light Operator Oversight

The system delivered significant operational impact:

- Achieved a consistent ~50 seconds per unit assembly and testing cycle time

- Automated assembly, dual-side leak testing, torque control, and barcode traceability

- Significantly reduced manual handling and dependency on skilled labor

- Defect handling with immediate diversion to reject path and high yield control

By integrating robotic assembly with built-in inspection, multi-stage testing, and torque automation, MWES enabled scalable, high-throughput cooler production with error detection and operator safety all improved.