The Challenge

Manual Cutlery Handling Was Slow, Repetitive, and Prone to Error

The customer needed a solution to streamline the post-injection molding process by:

- Removing utensils from spruce/dunnage efficiently

- Stacking parts into precise quantities quickly

- Feeding consistent stacks into case packing

- Reducing operator fatigue and improving accuracy

MWES was selected to deliver a scalable robotic solution capable of handling large volumes with zero drops and precise stacking at line speeds.

The Solution

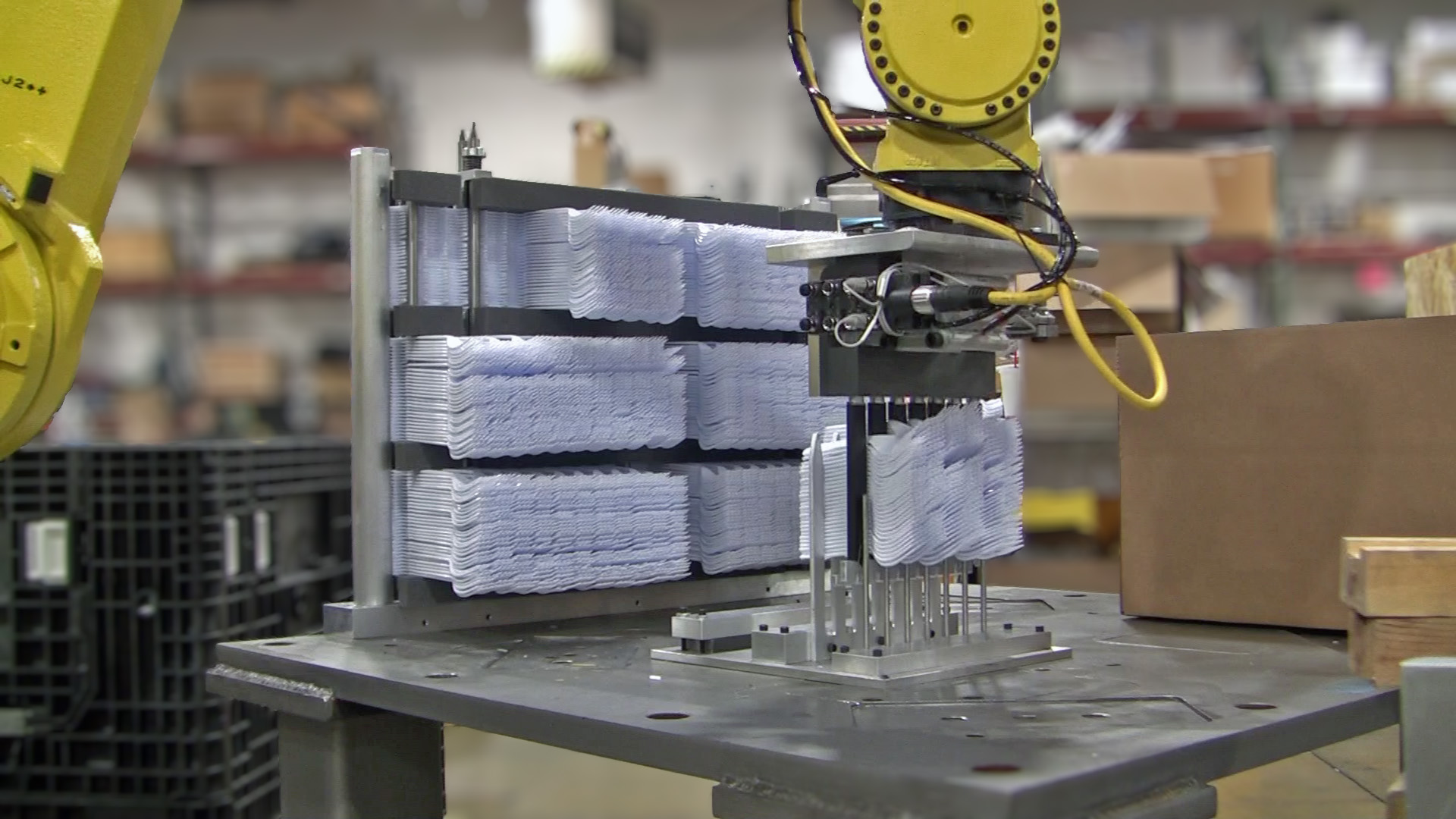

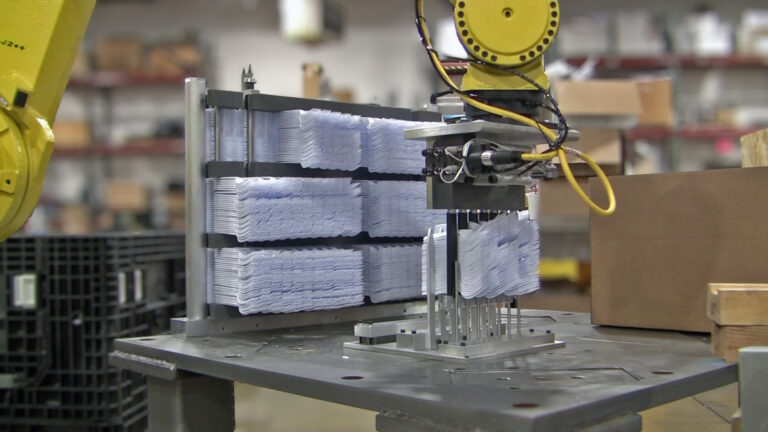

Vision-Guided Robotic Packaging with Integrated Stack Verification

MWES engineered an integrated automation cell featuring:

- Robot cell to pick, break off forks and spoons in stacks of 30

- Second robot to place stacked units into case-loading fixtures

- Overflow stack correction logic to manage missing utensils

- Laser-based height verification for stack accuracy

- Automated case forming, filling, sealing, and outfeed conveyor system

The system handles stacks of 600 utensils per case, ensuring precise quantity control and eliminating manual stepping.

The Results

800 Pieces Per Minute—Fully Automated, High-Accuracy Packaging

The MWES system delivered immediate benefits:

- Achieved up to 800 parts per minute packaging speed

- Eliminated repetitive manual handling and improved ergonomics

- Improved quality through consistent stacking and laser verification

- Reduced labor costs and dependency on manual operators

This robotic automation system significantly increased packing throughput, reliability, and operator safety—all while maintaining product accuracy.