The Challenge

High-Force Knurling Requires Automation for Precision and Safety

A major automotive supplier needed to automate a demanding manual knurling process on valve plates. The system had to:

- Handle the high pressures and forces exerted during knurling

- Orient randomly positioned parts accurately for consistent results

- Support multiple part types in one cell

- Capture defect data and report failures in real-time

MWES was chosen to design a robotic system that could perform reliable, high-volume knurling while embedding quality control and minimizing operator involvement.

The Solution

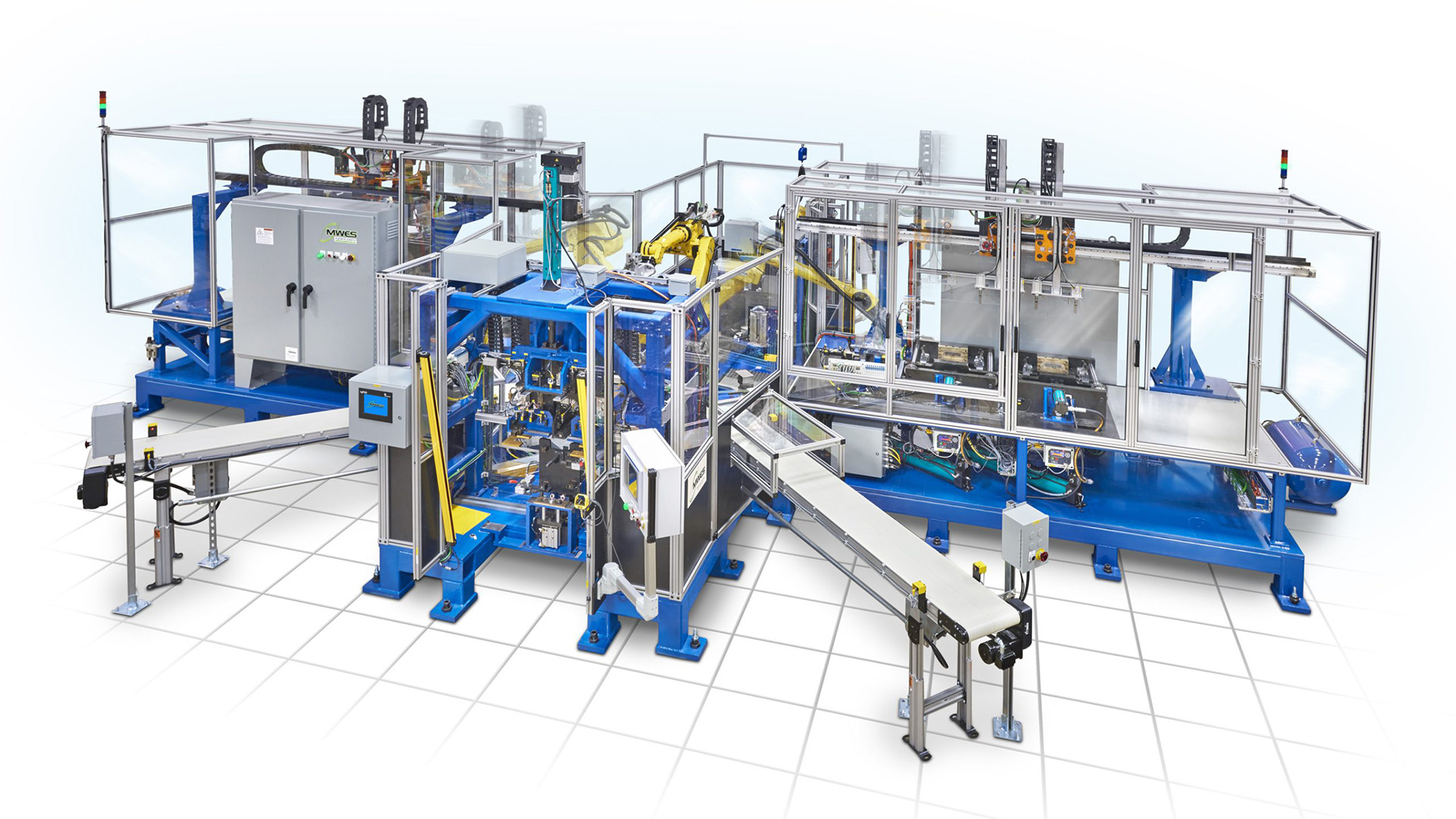

Vision‑Guided Robotic Knurling Cell with Automated QA

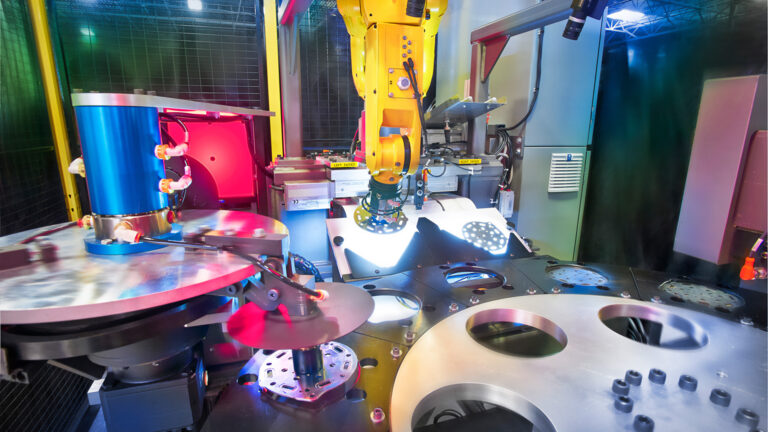

MWES engineered a fully robotic automation cell including:

- Two TOX 30-ton knurling presses managed within one compact cell

- One robot with magnetic EOAT and 2D vision camera for pickup and orientation

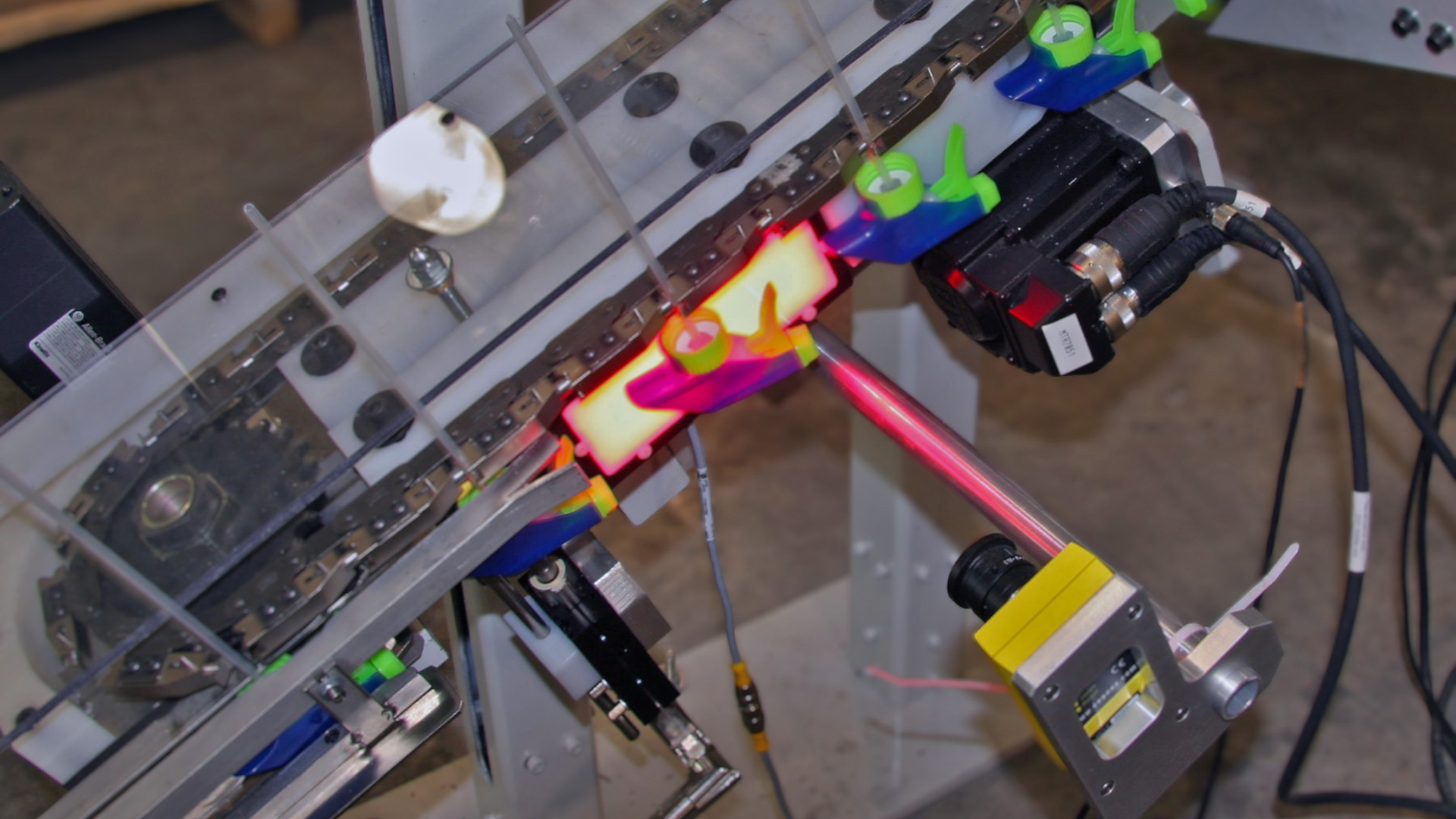

- Four-camera PPT vision system for detecting radial orientation and flipping misaligned parts

- Twelve-position dial table to support batching and varied configurations

- In-process defect detection and logging, linked to operator interface

- Safety rated to ISO 13849‑1:2006 Cat 3 and ANSI/RIA R15.06‑1999 standards

The system ensures proper orientation, consistent process execution, and embedded QA—delivering safe, repeatable knurling operations with minimal downtime.

The Results

High-Volume Operation with Embedded Quality & Minimal Operator Involvement

This robotic knurling cell provided measurable benefits:

- Smartphone-quality orientation accuracy, even with random part presentation

- Autonomous part flipping and consistent knurling across multiple part types

- Real-time defect detection and logging for full traceability

- No manual intervention or guesswork during production cycles

By leveraging advanced vision and robotic tooling, MWES helped the customer optimize throughput, ensure quality, and reduce manual labor in a high-force manufacturing process.