The Challenge

High-Precision Armor Cuts Without Disabling Operational Vehicles

Modifying armored military hardware requires accuracy—and minimal downtime or damage risk. The customer needed a solution to:

- Cut thick armored shell material accurately following variable field layouts

- Execute cuts without disassembly or removal of existing components

- Maintain operational integrity and reduce risk of collateral damage

- Repeat authorized cut patterns reliably across multiple vehicle units

MWES was selected for their expertise in integrating vision-controlled laser systems into high-stakes, precision-sensitive environments.

The Solution

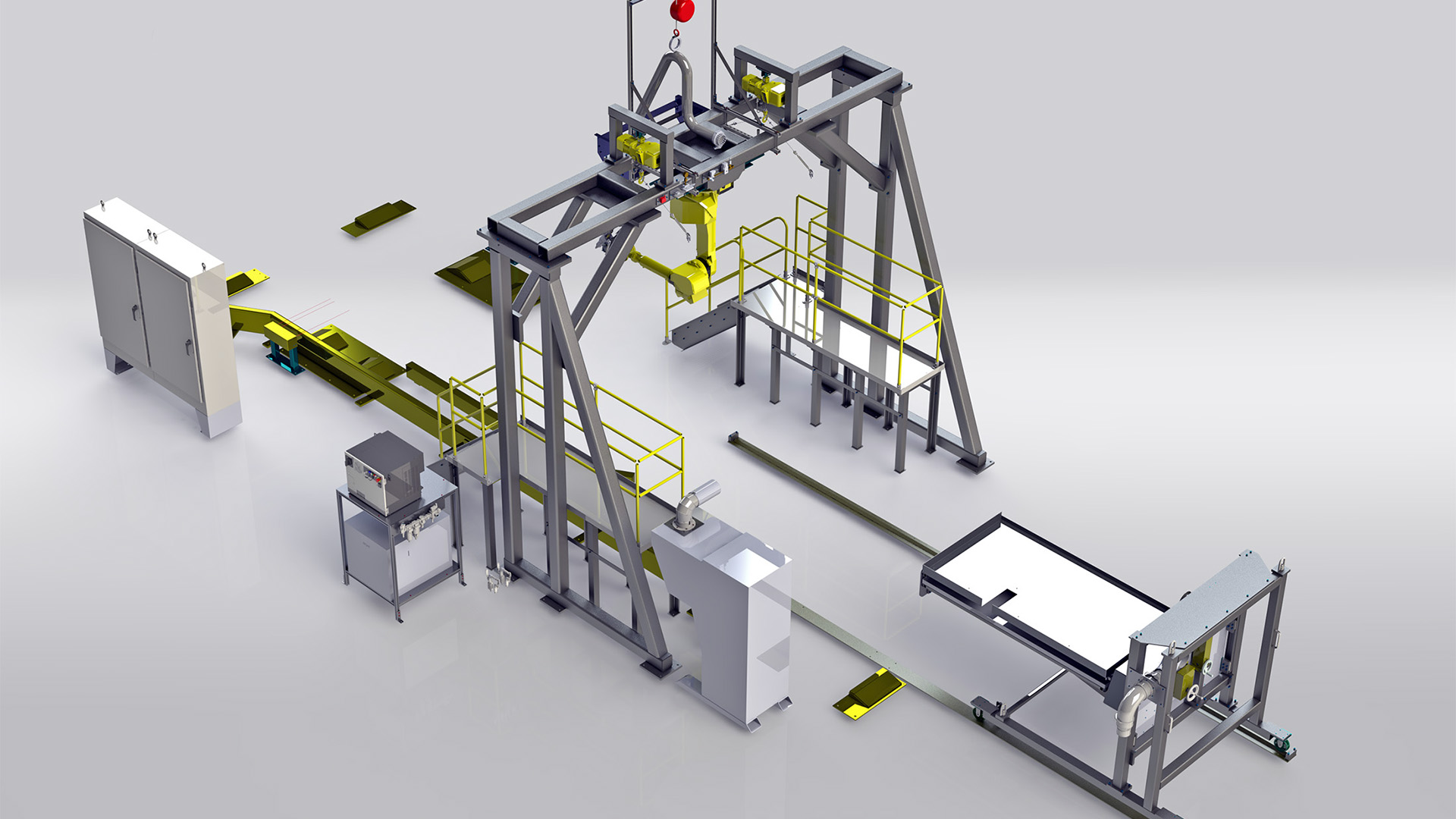

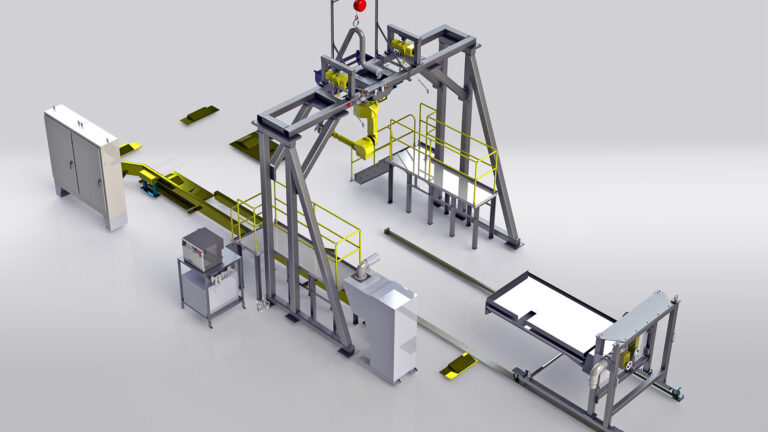

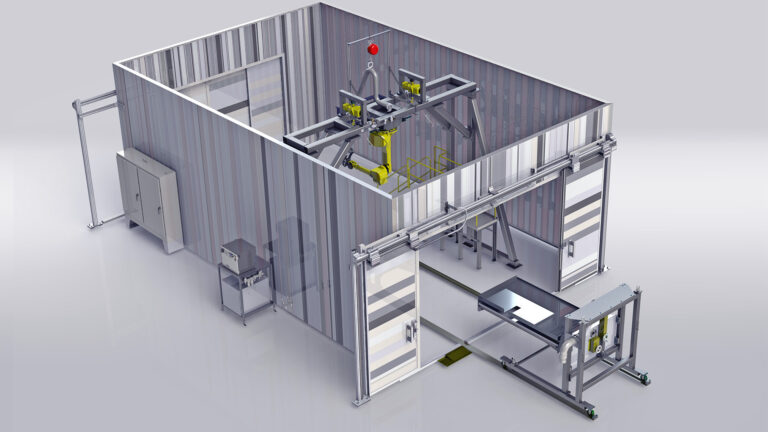

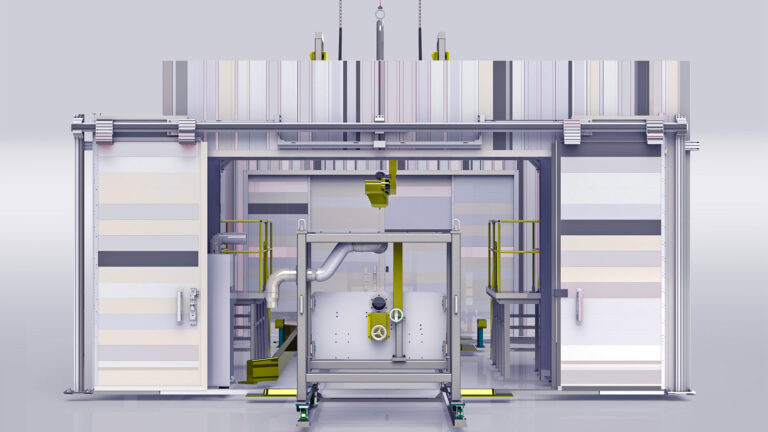

Vision-Guided Robotic Laser Cell with Adaptive Armor Tracking

MWES engineered a mobile robotic cell delivering the following capabilities:

- Robot-mounted high-power laser cutter calibrated to armor thickness and alloy types

- Vision system to detect and follow custom cut-pattern templates on armored shells

- Programmable motion paths to replicate cutting routines across multiple vehicles

- Enclosure and safety interlocks to ensure operator and equipment protection during cutting

- On-vehicle fixturing system ensuring stability and alignment during the cut

This turnkey solution automates precision laser cutting directly onto assembled armored vehicles, avoiding disassembly, while delivering consistent, clean results.

The system delivers adaptable laser cutting ability for armored components, combining vision-based path following with robot manipulation for high-accuracy modifications in operational settings.

The Results

Operational Laser Modifications with Zero Disassembly & High Precision

Deployment of the system produced key benefits:

- Enabled field-level armor modifications without full vehicle teardown

- Delivered repeatable, precise laser cuts aligned to vision-guided templates

- Eliminated risk of operator error and expensive retrofit corrections

- Supported scalable deployment to multiple vehicles with uniform cut quality

By integrating vision-guided robotics into armored vehicle modification workflows, MWES provided a robust, safe, and flexible automation system—minimizing disruption while maximizing precision.