The Challenge

Deburring and Torquing Heavy Rods Reliably Without Manual Bottlenecks

Manual deburring and assembly of connecting rods was labor-intensive, inconsistent, and prone to safety concerns. The customer needed a robotic system that would:

- Process trays of 24 rods per cycle on conveyor infeed

- Perform deburring, inspection, and final torque assembly

- Accommodate heavy, high-mix parts with reliable automation

- Maintain production speeds with minimal operator input

MWES was selected for its experience developing robotic material removal systems with integrated torque automation.

The Solution

Robotic Deburring & Torque Automation Cell with Conveyor Integration

MWES delivered a complete robotic cell including:

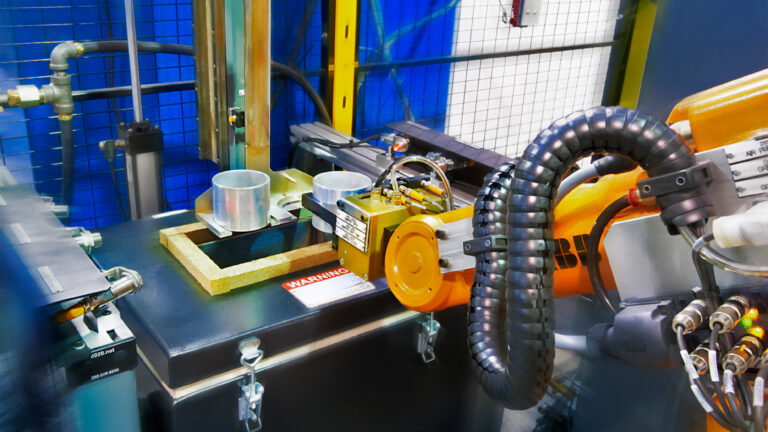

- Tray-based conveyor infeed delivering stacks of connecting rods

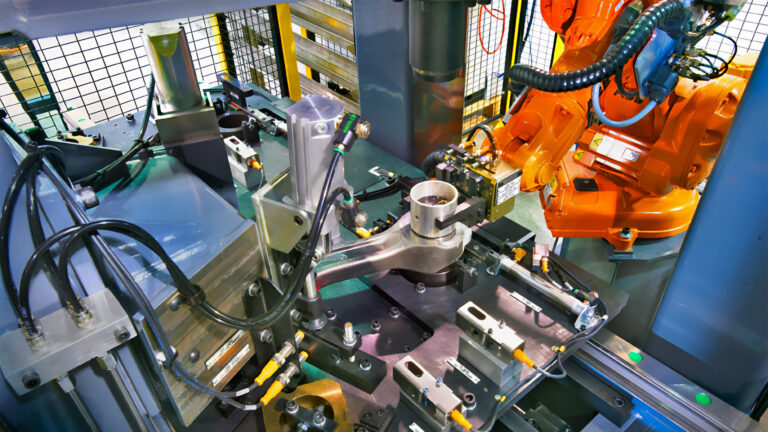

- ABB-controlled robot picking each rod for sequential processing

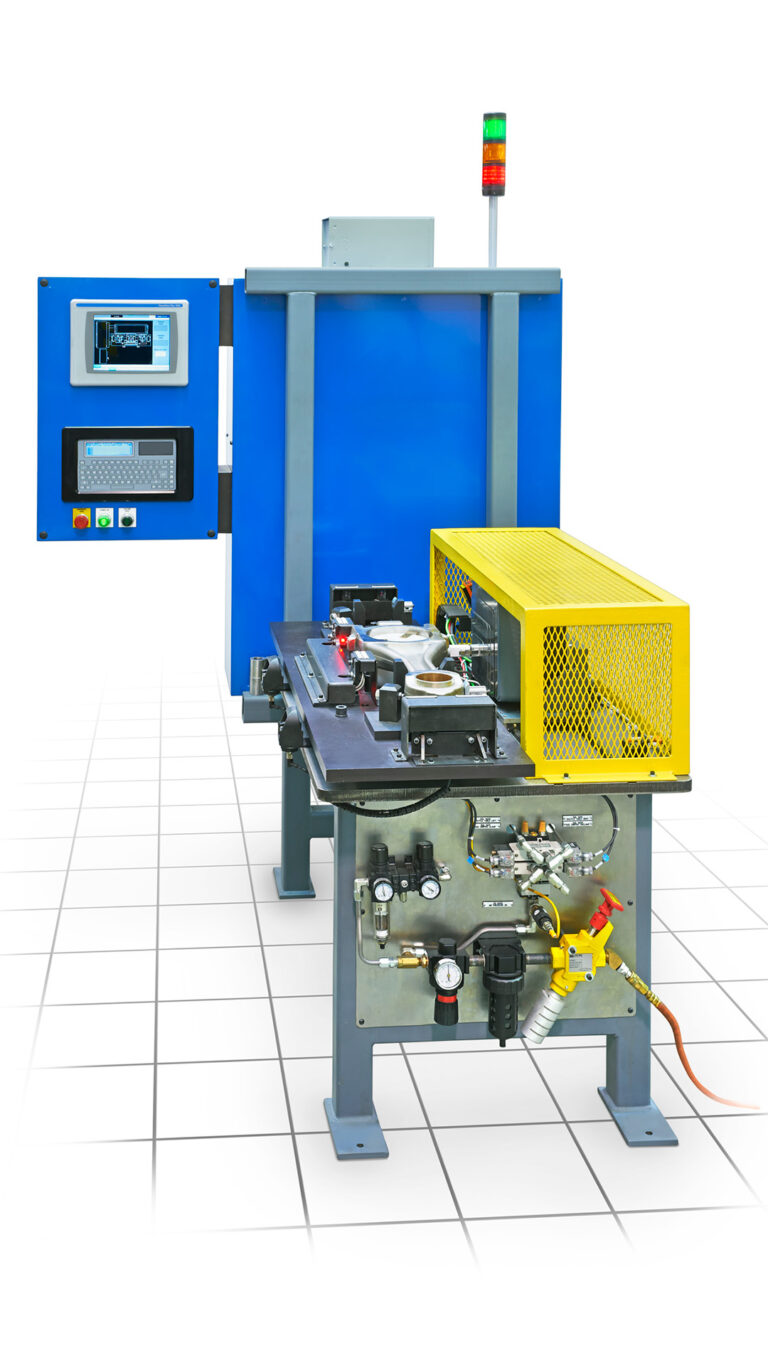

- Deburring station to remove burrs and flash from rods

- Part gage inspection machine to verify dimensions

- Bolt insertion and torque station to fasten rod caps with precise torque

- Tray-based outfeed conveyor for completed parts

The system flows rods through deburring, inspection, and torque application seamlessly—while maintaining consistent part throughput and minimal manual intervention.

Summary: This integrated automation cell provided multi-stage rod finishing and assembly in a continuous workflow with full part tracking and minimal labor dependency

The Results

Three-Minute Cycle Time, Labor Reduction & Uniform Quality

MWES’s solution delivered measurable benefits:

- Achieved approximately 3-minute cycle time per connecting rod

- Enabled throughput of up to 90,000 units per year

- Eliminated manual handling during deburring and torque assembly

- Delivered consistent part quality and reduced rework

By fully automating rod finishing and fastening, MWES helped the manufacturer scale operations with predictable cycle times and repeatable quality—all while reducing manual labor and process variability.