The Challenge

Integrating a Safe, Traceable Heating Step into an Existing Production Line

Adding thermal processing into an existing assembly flow posed multiple challenges. The customer needed a system to:

- Feed parts into a low-temperature oven automatically

- Track parts across multiple storage levels within the oven using barcode scanning

- Reclaim parts precisely after specific dwell times across six oven conveyors

- Maintain part flow without disrupting the larger line operations

MWES was selected to deliver a conveyor-based heating solution that integrates barcode tracking, tiered storage, and timed controlled delivery across infeed and outfeed zones.

The Solution

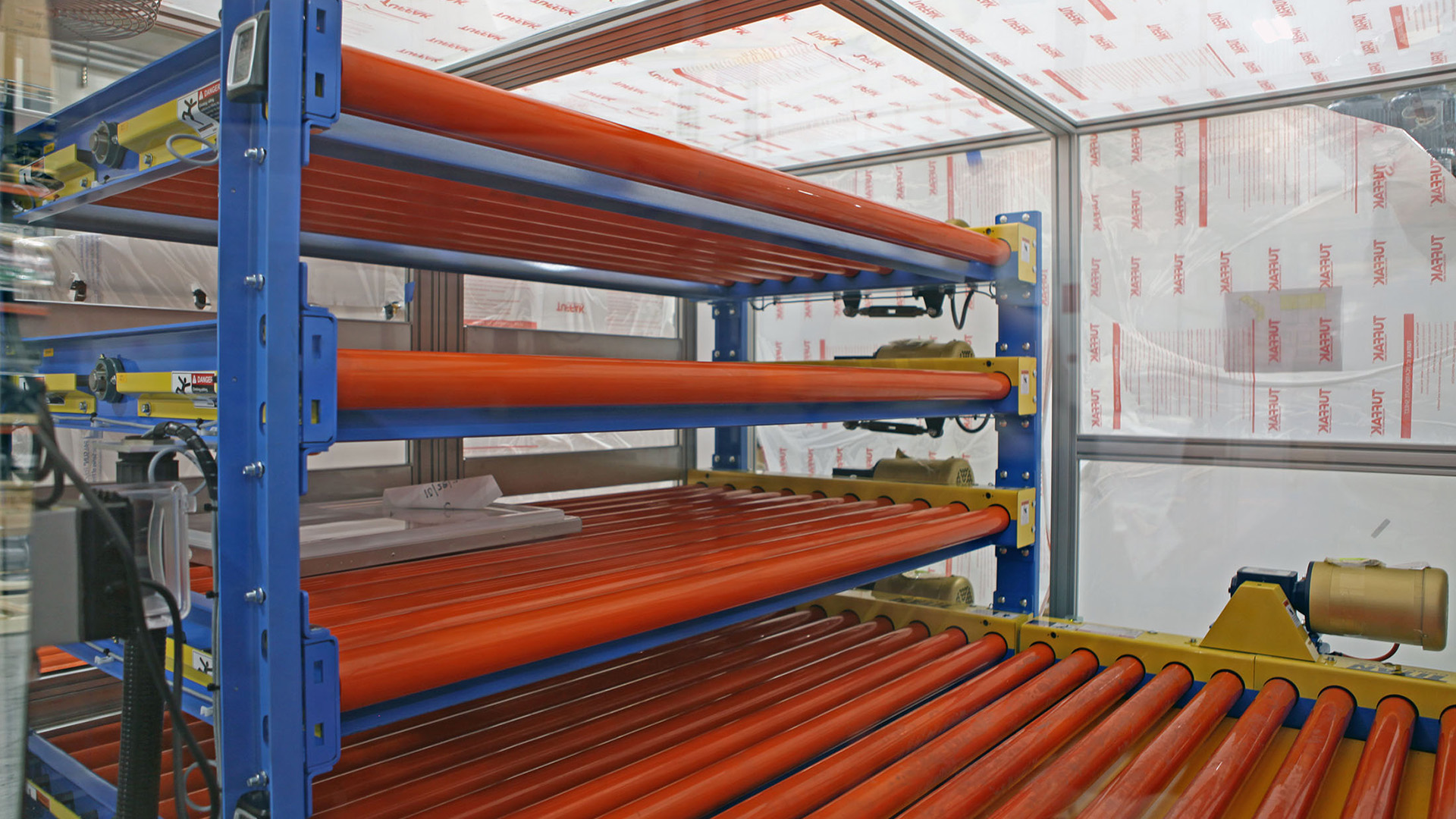

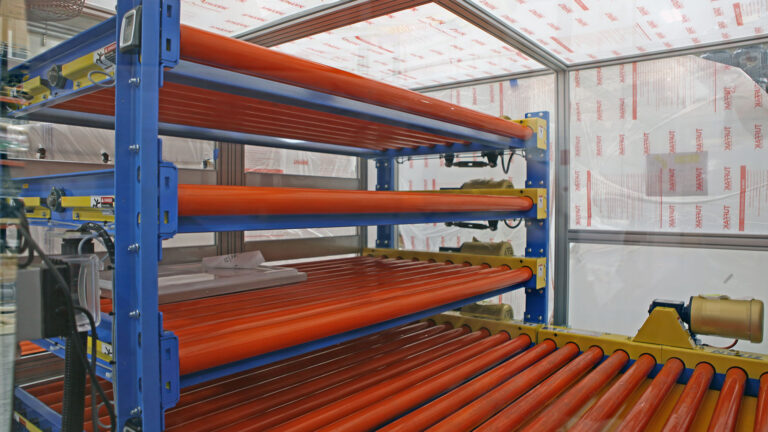

Conveyor System with Lift-Based Oven Storage, Barcode Tracking & HMI Control

MWES delivered an automation system that includes:

- An infeed conveyor where operators load parts and scan barcodes into the PLC

- Six separate conveyors inside the oven with lift-based storage for timed dwell control

- Multiple remote conveyors to feed adjacent foaming stations as part of the assembly line

- HMI screens to allow operators to select specific parts and retrieve them when ready

MWES engineered a precise, timed heating cell that integrates storage, tracking, and conveyor logic to manage part flow through the oven—providing traceability and control without manual part repositioning.

The Results

Precise Oven Processing with Reduced Handling and Predictable Throughput

This turnkey heating solution delivered the following operational benefits:

- 120-second in-and-out cycle for heating each loaded door or mullion

- Capability to handle parts up to 70 x 36 in and 100 lbs safely

- Barcode-linked tracking ensures accurate part selection and timing

- Eliminated manual part retrieval and staging within the heated zone

By automating oven exposure timing and part handling, MWES helped the customer integrate thermal pre-processing without labor-intensive manual steps—improving throughput predictability, traceability, and safety on the existing line.