The Challenge

Maintaining Speed, Hygiene & Precision in Food-Grade Block Handling

Handling food-grade cheese at high speed presents both operational and sanitary challenges. The customer needed a solution that could:

- Process up to 150 cheese blocks per minute reliably

- Identify and reject defective blocks using in-line vision

- Rotate accepted blocks precisely without marking or damaging them

- Meet USDA, FDA, and WDA food safety regulations

MWES was selected to design a hygienic, high-throughput robotic system that safely handled delicate food products at commercial scale.

The Solution

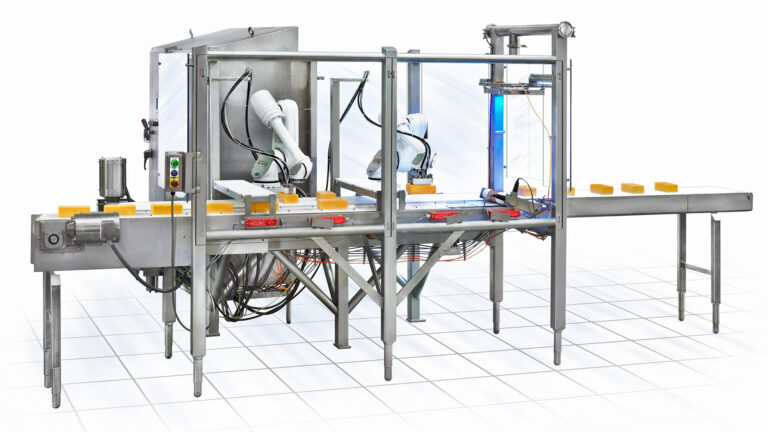

Dual‑Robot Vision-Guided Rotation & Rejection Cell with Food-Safe Vacuum EOAT

MWES delivered a robust automation system featuring:

- Two FANUC M430iA/4FH robots using FDA-compatible vacuum cups

- iRVision 2D tracking camera to identify good vs. reject blocks in real time

- Conveyor buffers grouping 20‑30 blocks per robot to smooth workflow

- Precise 90° rotation and placement onto web-based packaging for accepted blocks

- Rejected blocks diverted into a separate bin via conveyor system

This cell enables high-speed, food-safe handling by automating inspection, orientation, and rejection—with no product marking and minimal operator touch.

The Results

150 ppm Throughput, Flexible SKU Handling & Clean, Repeatable Operation

The automated cell delivered significant improvements in speed, flexibility, and sanitation:

- Sustained 150 cheese blocks per minute throughput

- Configured to handle 30+ block dimensions, with new sizes added via HMI

- Fully compliant with USDA, FDA, and WDA food safety standards

- Eliminated manual sorting and handling of sensitive food product

By integrating rapid vision inspection, precision robotics, and hygienic handling, MWES provided a scalable, quality-driven solution that reduced labor, improved safety, and maximized packaging throughput.