Custom Converting Systems

Tailored to Your Material and Production Needs

No two converting processes are identical. MWES develops fully customized systems designed around your substrate properties, production rates, and final product requirements. Whether you need to laminate multi-layer structures, slit and rewind rolls, or integrate specialty processes, our engineering team creates modular systems that optimize performance while maintaining precise web control and alignment throughout the line.

Integrated Converting Capabilities

Our converting systems can be configured to include any combination of the following processes:

- Coating and Laminating Stations for adhesives, films, and barrier materials

- Slitting and Rewinding Modules for clean, accurate edge quality

- Ultrasonic or Thermal Welding for sealing nonwoven and plastic webs

- Inline Inspection and Sensing Systems for defect detection and process control

- Automated Roll Handling and Splicing Equipment for continuous operation

Beyond Converting — Complete System Integration

MWES goes beyond standalone converting equipment by integrating packaging automation, robotic material handling, and full-line control systems into one cohesive solution. Our engineering teams combine expertise in factory automation, robotics, and motion control to streamline every stage—from web processing to finished product packaging. By unifying all line functions, MWES helps manufacturers reduce manual handling, increase throughput, and ensure consistent product quality.

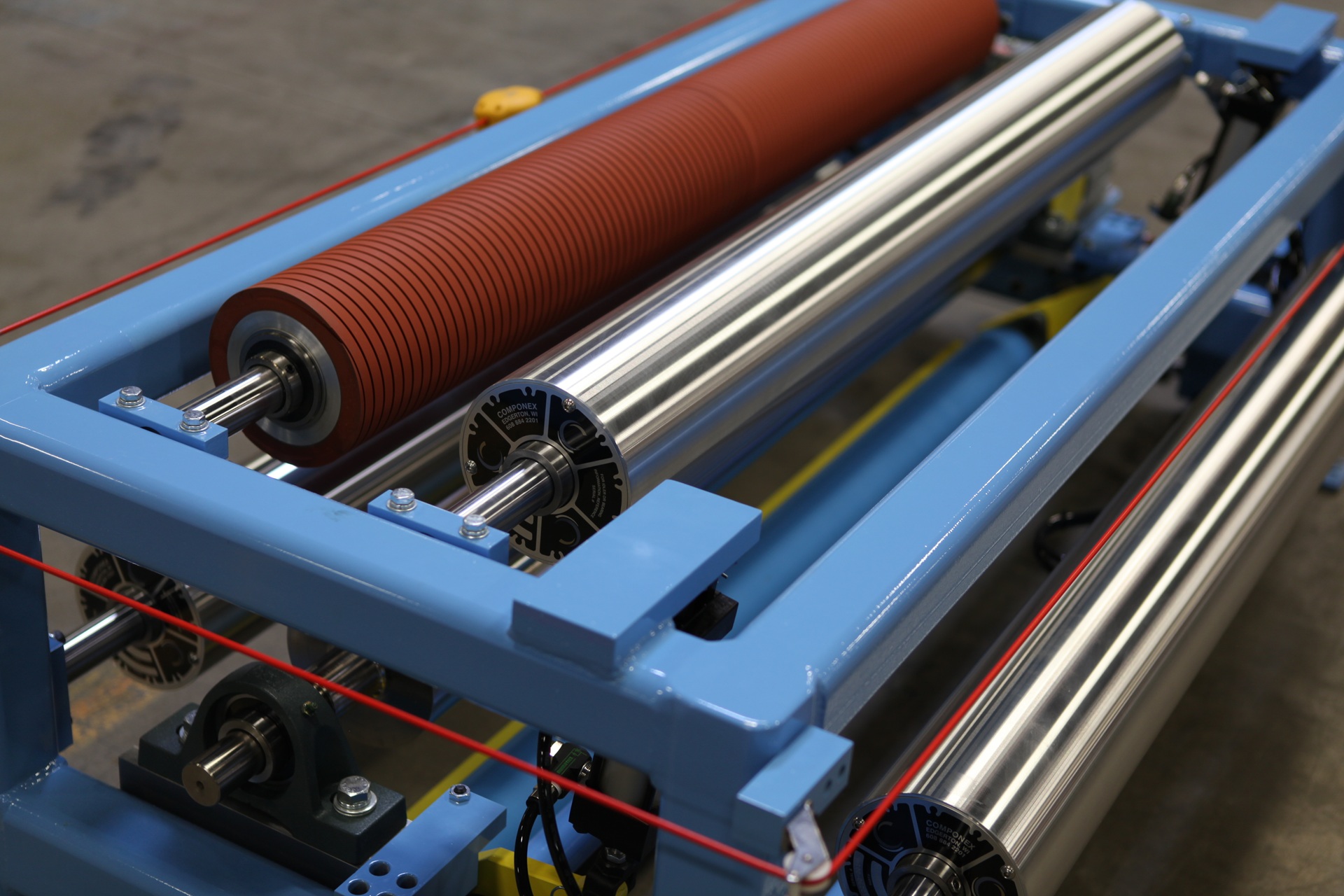

Designed for Performance and Longevity

Each MWES converting system is built for high precision, low maintenance, and long-term dependability. We incorporate proven web handling practices—optimized roller geometry, synchronized drive systems, and advanced control software—to maintain stability even at high speeds. Our systems are designed for ease of setup, minimal waste, and seamless integration into your existing operations.

From custom coating and laminating lines to fully automated converting and packaging systems, MWES provides the engineering expertise and integration capabilities to optimize your production.

Partner with us for a complete, end-to-end converting solution that enhances quality, efficiency, and competitiveness.