The Challenge

Automating Complex Plate Machining in a Single Operator-Run System

This customer sought to consolidate multiple machining steps into one automated system with minimal operator involvement. Key challenges included:

- Machining both sides of steel plates with high precision

- Automating loading of bar stock and slugs for part production

- Integrating gauging, washing, and rejection handling

- Maintaining single-operator simplicity across the full system

MWES was chosen for its experience in turnkey machining and robotic automation systems that handle complex material flows.

The Solution

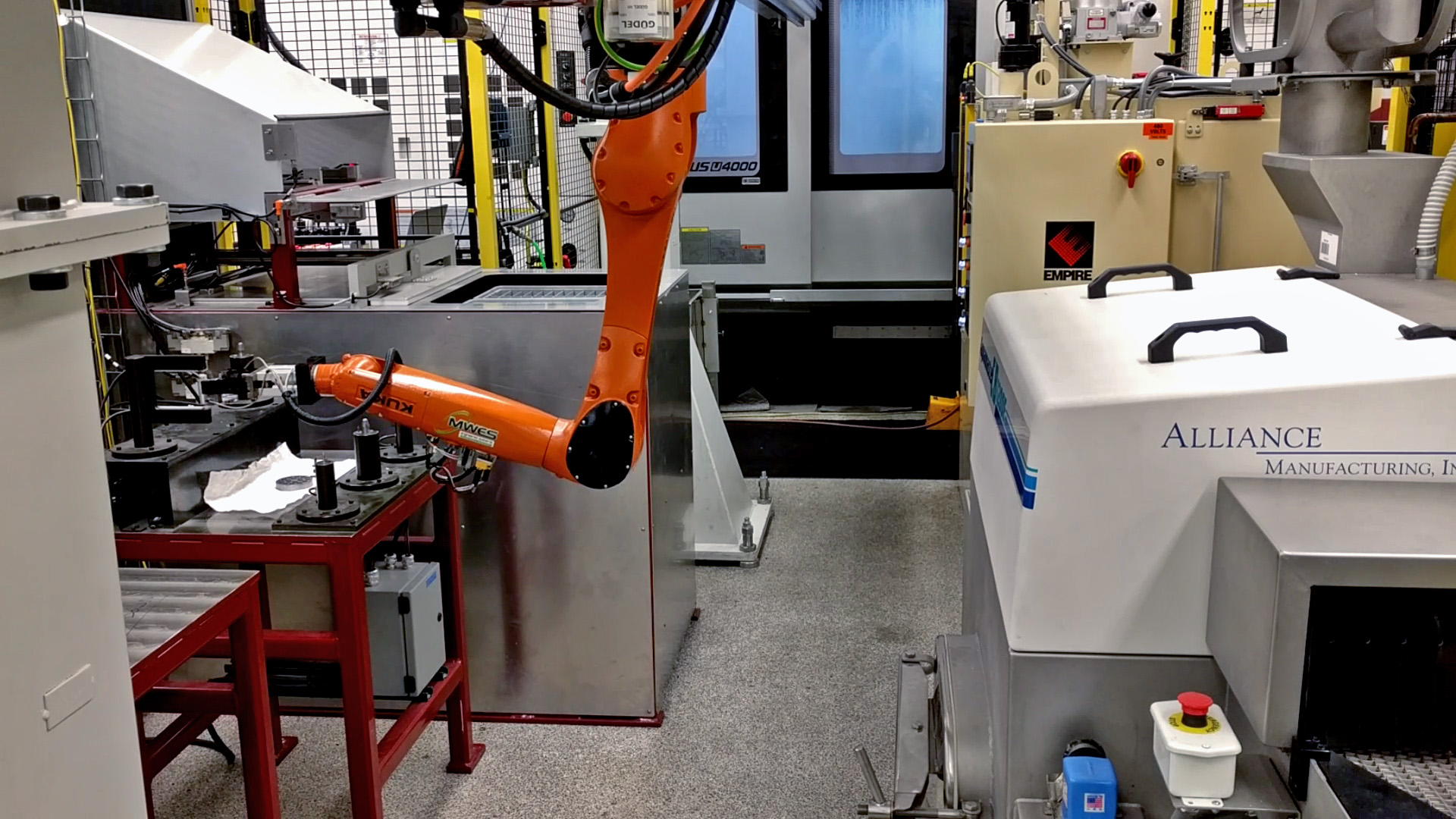

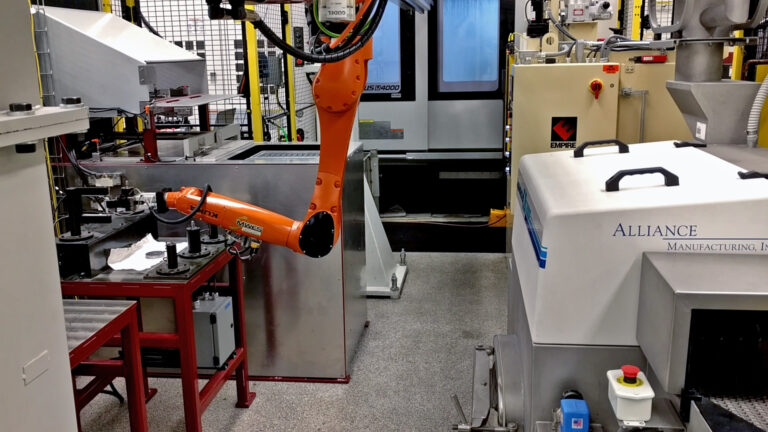

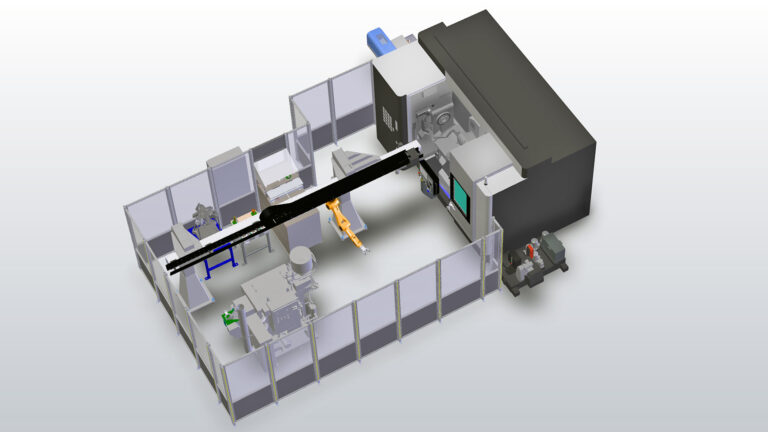

Single-Operator Robotic Cell With Automated Machining, Inspection & Tray Packing

MWES delivered a fully integrated robotic machining system that included:

- Automated bar feed and slug loading for parts up to 4” in diameter

- Dual-headstock machining centers for face and diameter processing

- Robotic unloading, part deburring, washing, and in-process gauging

- Rejection handling and final part placement into packing trays

The cell runs independently after HMI setup and minimal operator tasks, maintaining high-speed throughput and part accuracy with automatic part handling from start to finish.

The Results

Higher ROI, Increased Throughput & Reduced Operator Burden

The MWES automation solution produced measurable benefits:

- Increased machining efficiency with continuous bar and slug processing

- Reduced need for skilled operator intervention

- Improved part consistency with integrated gauging and rejection logic

- Enabled reliable tray packing and inventory management via HMI alerts

By automating an otherwise labor-intensive process, MWES helped the customer achieve faster cycle times and consistent production with just one operator.