The Challenge

Automating High-Speed Shrink Tube Placement with Minimal Footprint

The customer needed a compact, ergonomic system to automate shrink-tube positioning and assembly onto printed card stock:

- Ensure operator safety and simplify handling of cut tubing and roll stock

- Achieve quick, mistake-proof changeovers between product recipes

- Maintain sub-millimeter cut-length accuracy (± 0.015″)

- Deliver consistent throughput of up to 12,000 assemblies per hour

MWES was selected to design a machine integrating web feeding, robotic pick-and-place, and marking—with minimal footprint and easy future scalability.

The Solution

Multi-Robot Web Assembly Cell with Precision Cut, Tape, Vision & Marking

MWES delivered a fully integrated shrink tube assembly machine featuring:

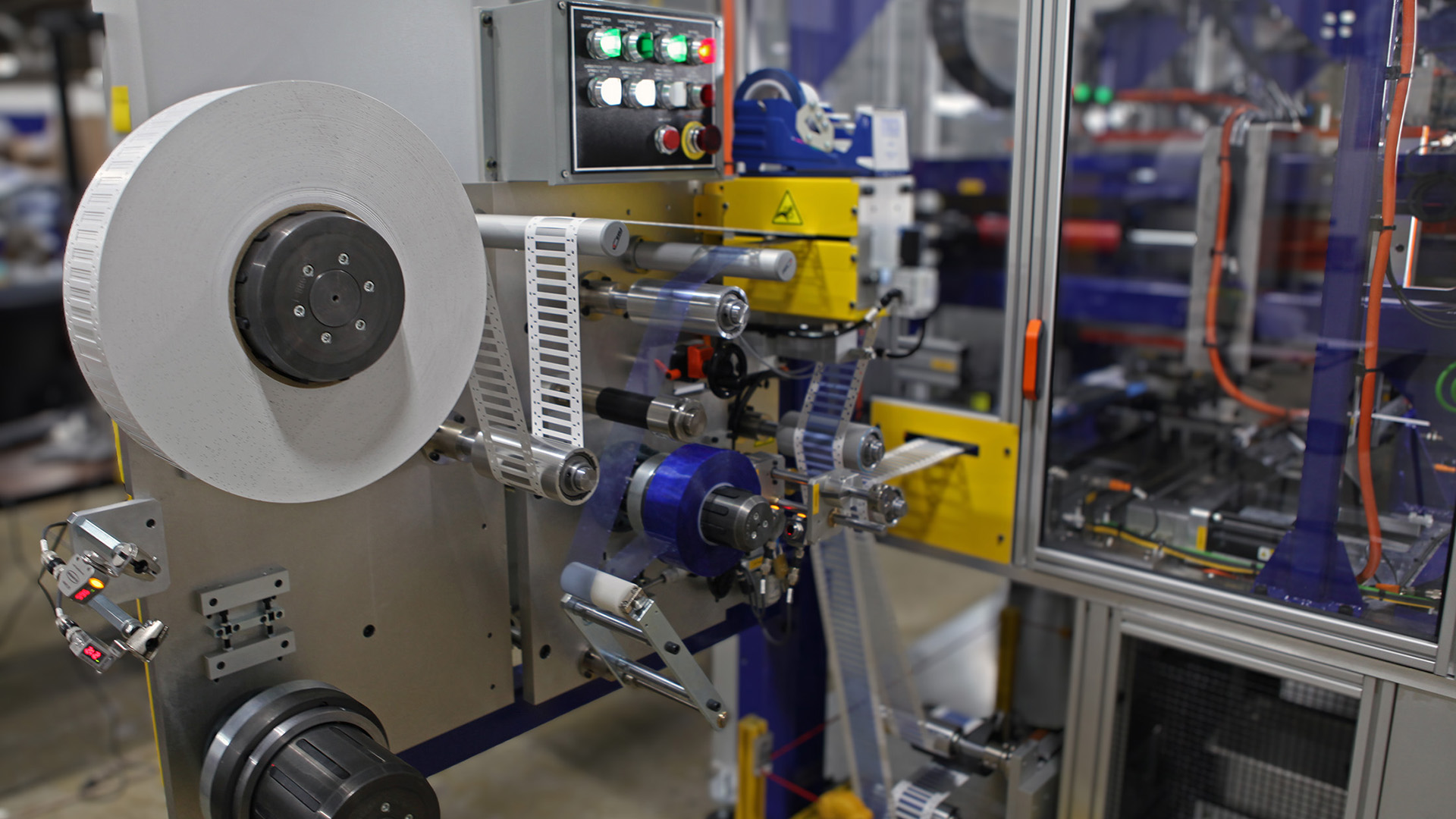

- Web unwind stations for tubing, cardstock, and pressure-sensitive tape

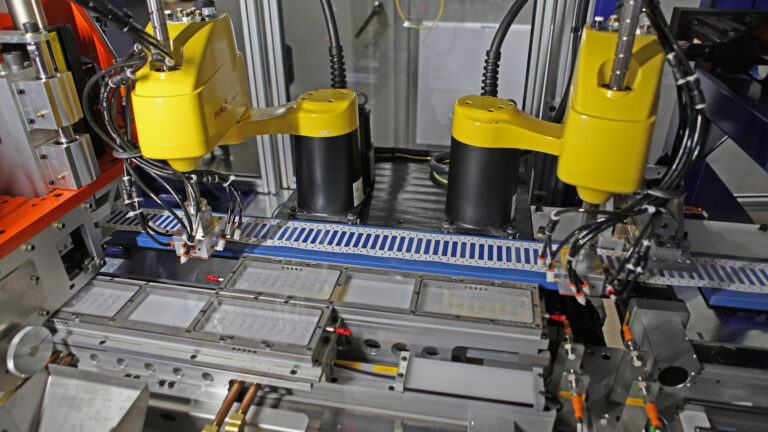

- Four SCARA-style robots synchronized to pick, align, and place cut tubing segments onto exposed tape windows

- Laser and vision-guided detection for verifying cut location and placement accuracy

- In-line printing system to label assemblies before rewind onto fixed core spools

- HMI-driven recipe control for SKU changeover and system adjustment

This automated cell streamlines cutting, placement, marking, and winding into a continuous, integrated machine—delivering repeatable, accurate tube assembly without manual alignment.

The Results

High Throughput with Repeatable Accuracy and Reduced Labor

The implemented system delivered substantial value for the customer:

- Achieved consistent output of 12,000 tubes/hour

- Met stringent cut-length tolerance of approximately ± 0.015 inches

- Eliminated ergonomic risk and manual variability in tube placement

- Enabled compact, scalable automation tailored to low-footprint production needs

By integrating robots, web handling, vision, and marking into one cell, MWES helped the customer achieve precise, high-speed tubing assembly with minimal human involvement—boosting quality, consistency, and throughput.